Luncheon meat containing brown algae dietary fiber and preparation method of luncheon meat

A technology of dietary fiber and dietary fiber powder is applied to the field of luncheon meat containing brown algae dietary fiber and its preparation, which can solve the problems of digestive disorders, obesity, and incompatibility with the needs of rich and balanced nutrition, and achieves increased dietary fiber content and balanced nutrition. , to ensure the effect of water retention and structural quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

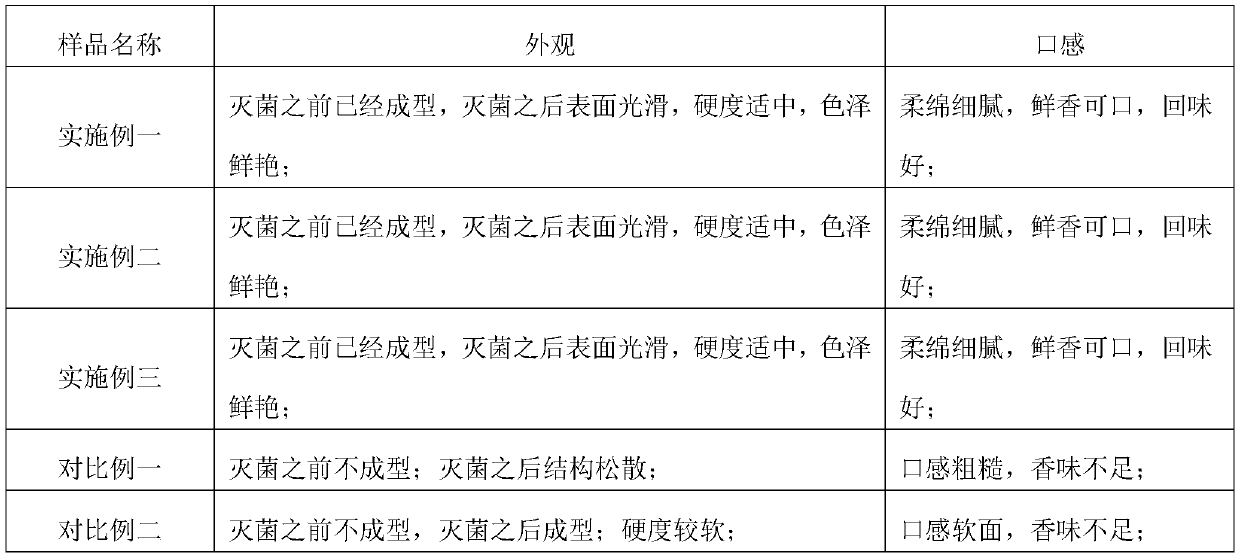

Examples

preparation example Construction

[0028] A kind of preparation method of the lunch meat containing brown algae dietary fiber of the present invention comprises the following steps:

[0029] 1) Pre-treatment of raw materials: take pork, chicken and pig fat, rinse and remove impurities to obtain raw meat;

[0030] 2) ground meat: mix the raw meat obtained in step 1), and ground the meat to obtain meat grains;

[0031] 3) Pickling: Take edible salt, sweetener, nitrite and phosphate, and mix to obtain a mixture; add the mixture to the meat granules obtained in step 2), stir evenly, at 0-4°C, Marinate for 48-72 hours to get marinated meat;

[0032] 4) Stirring: take brown algae dietary fiber powder, ice chips, protein powder, umami regulator, starch, pigment and flavor regulator, add brown algae dietary fiber powder and ice chips to the marinated meat obtained in step 3), and stir , and then continue to add protein powder, umami taste regulator, starch, pigment and flavor regulator to it, and mix evenly to get me...

Embodiment 1

[0037] A kind of preparation method of the lunch meat containing brown algae dietary fiber of the present invention comprises the following steps:

[0038] 1) Configuration of brown algae dietary fiber powder: take 50 parts of sodium alginate, 10 parts of wakame oligosaccharides, 10 parts of food grade calcium carbonate and 10 parts of gluconolactone, mix them to make brown algae dietary fiber powder, sodium alginate Viscosity is 500mPa · s;

[0039] 2) Preparation of raw materials: Weigh 20 parts of pork, 8 parts of chicken, 5 parts of pig fat, 45 parts of ice chips, 2.5 parts of protein powder, 1.2 parts of edible salt, 0.8 parts of white sugar, 0.12 parts of monosodium glutamate, and 0.012 parts of sodium nitrite , 2.5 parts of brown algae dietary fiber powder obtained in step 1), 2.5 parts of cornstarch, 0.05 part of sodium pyrophosphate, and 1 part of essence;

[0040] 3) Pre-treatment of raw materials: take pork, chicken and pig fat, rinse and remove impurities to obta...

Embodiment 2

[0047] A kind of preparation method of the lunch meat containing brown algae dietary fiber of the present invention comprises the following steps:

[0048] 1) Configuration of brown algae dietary fiber powder: Take 70 parts of potassium alginate, 5 parts of kelp oligosaccharide, 15 parts of food grade calcium sulfate and 5 parts of sodium pyrophosphate, and mix them to make brown algae dietary fiber powder. The viscosity of potassium alginate is 700mPa · s;

[0049] 2) Raw material preparation: Weigh 30 parts of pork, 10 parts of chicken, 3 parts of pig fat, 30 parts of ice chips, 1.0 part of protein powder, 0.8 parts of edible salt, 1.5 parts of white sugar, 0.08 parts of monosodium glutamate, and 0.014 parts of sodium nitrite , 1.5 parts of brown algae dietary fiber powder obtained in step 1), 5.0 parts of cornstarch, 0.2 part of sodium tripolyphosphate, and 1 part of pigment;

[0050] 3) Pre-treatment of raw materials: take the thawed pork, chicken and pig fat, rinse and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com