Modified clay seawater mixed liquid spraying system for red tide elimination

A spraying system and mixed liquid technology, applied in the field of marine pollution control, can solve the problems of shortening a single operation time, affecting the radius of a single spraying operation, complex equipment structure, etc., to prolong the time of a single operation and expand the radius of a single operation , the effect of large spraying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

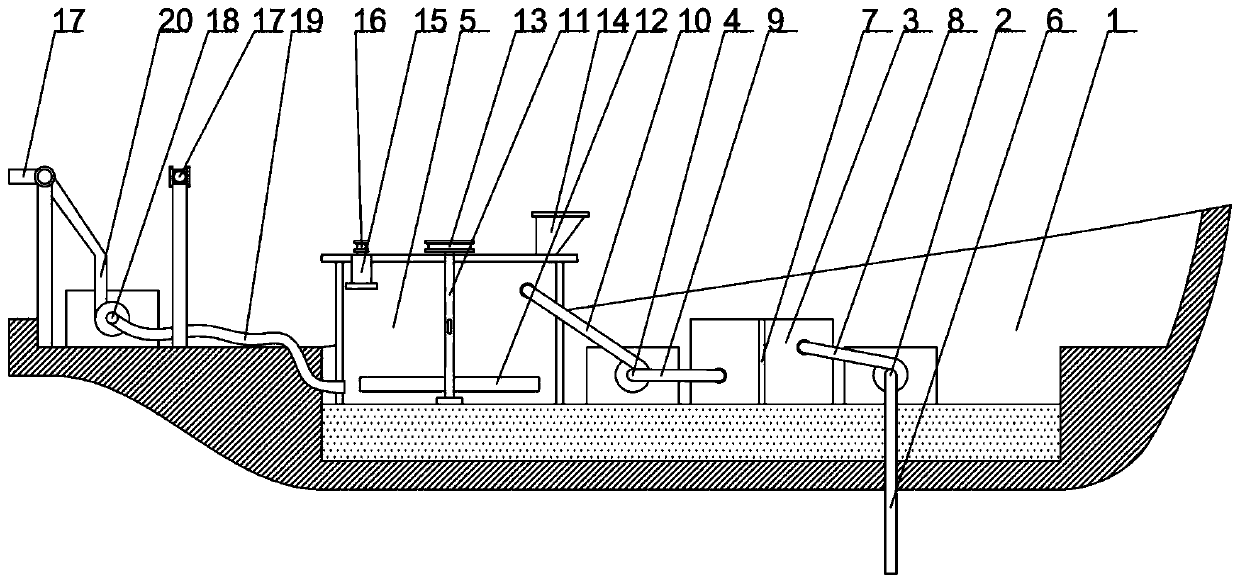

[0016] In order to illustrate the technical solution of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings. Obviously, the accompanying drawings described below are only an embodiment of the present invention. For those of ordinary skill in the art, On the premise of not paying creative work, other embodiments obtained according to the drawings and embodiments all belong to the protection scope of the present invention.

[0017] A modified clay seawater mixed solution spraying system for red tide elimination, the modified clay seawater mixed solution spraying system is mounted on the hull 1 through threaded fasteners as a whole, and the modified clay seawater mixed solution spraying system is from front to back It includes a first water pump 2, a filtered water tank 3, a second water pump 4, a mixing chamber 5 and a spraying device in sequence, the water inlet of the first water pump 2 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com