Modified film-forming resin containing acid inhibitor and preparation method thereof and photoresist composition

A technology of film-forming resin and acid inhibitor, which is applied in the direction of photosensitive materials, optics, and opto-mechanical equipment used in optomechanical equipment, and can solve the problem of poor film-forming ability of photoresist, mismatch of mutual solubility, photoresist film Brittle cracks and other problems, to achieve the effect of good film forming ability, stable photolithography performance, improved resolution and line width roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

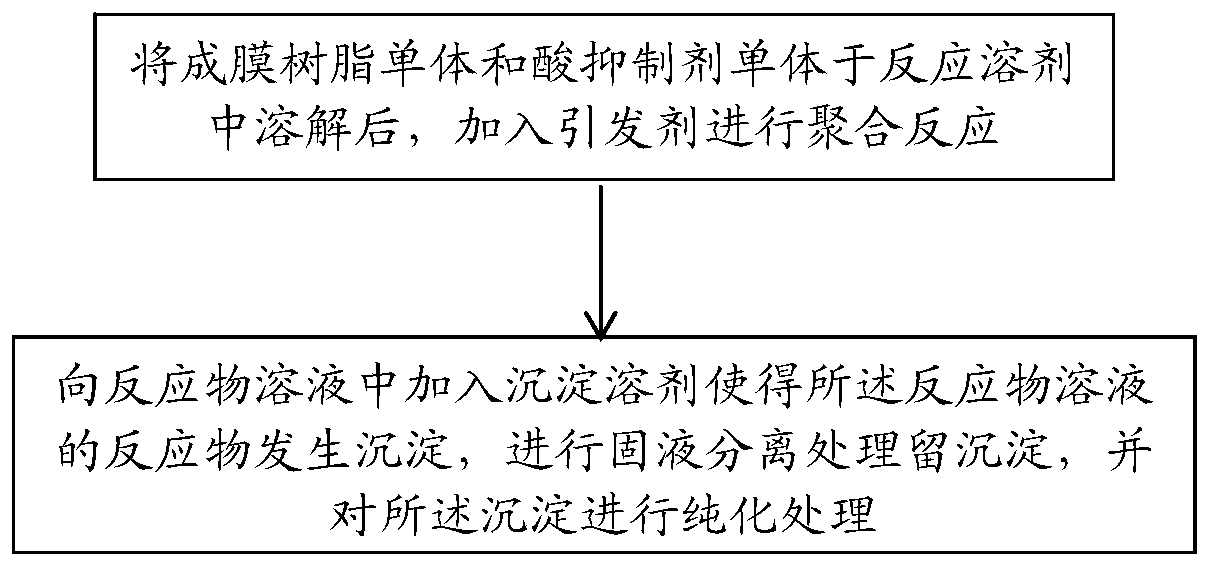

[0061] On the other hand, based on the modified film-forming resin described above, the embodiment of the present invention also provides a preparation method of the modified film-forming resin. Described modified film-forming resin preparation method technological process is as figure 1 As shown, it includes the following steps:

[0062] S01. Under a protective atmosphere, after dissolving the film-forming resin monomer and the acid inhibitor monomer in the reaction solvent, adding an initiator solution to carry out a polymerization reaction to obtain a reactant solution;

[0063] S02. Adding a precipitation solvent to the reactant solution to cause precipitation of the reactant in the reactant solution, leaving the precipitate and separating the solution for treatment, and purifying the precipitate.

[0064] Wherein, the film-forming resin monomer and the acid inhibitor monomer in step S01 are the same as the film-forming resin monomer and the acid inhibitor monomer describ...

Embodiment 1-1

[0080] This embodiment provides a modified film-forming resin containing an acid inhibitor and a preparation method thereof. The modified film-forming resin is formed by polymerizing film-forming resin monomers and acid inhibitor monomers. Specifically, the reaction formula and specific structural formula of the modified film-forming resin containing acid inhibitor are as follows:

[0081]

[0082] The preparation method of the modified film-forming resin containing acid inhibitor comprises the steps of:

[0083] (1) 30g of polar film-forming resin monomer M1, 50g of acid protection monomer M2, 19.35g of non-polar film-forming resin monomer M3 and 0.65g of acid-inhibiting monomer 1 are added into a reactor full of nitrogen, and Add 100g of the first tetrahydrofuran into the reaction kettle, stir the reaction kettle to 66° C., then add dropwise (dropping time is 10min) a mixture of 20g of the second tetrahydrofuran and 2g of benzoyl peroxide into the reaction kettle. The m...

Embodiment 1-2

[0087] This embodiment provides a modified film-forming resin containing an acid inhibitor and a preparation method thereof. The modified film-forming resin is polymerized from film-forming resin monomers, acid inhibitor monomers and hydroxyl-containing monomers. Specifically, the reaction formula and specific structural formula of the modified film-forming resin containing acid inhibitor are as follows:

[0088]

[0089] The preparation method of the modified film-forming resin containing acid inhibitor comprises the steps of:

[0090] (1) 30g of polar film-forming resin monomer M1, 50g of acid-protected monomer M2, 19.20g of non-polar film-forming resin monomer M3, 0.65g of acid-inhibiting monomer 1 and 0.15g of hydroxyl-containing monomer 376 were added In the reaction kettle filled with nitrogen, add 100g of the first ethyl acetate into the reaction kettle, stir the reaction kettle to 77°C, and then drop the second ethyl acetate into the reaction kettle (dropping time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com