A kind of bronzing UV varnish and its preparation method and application

A technology of varnish and photosensitizer, which is applied in the direction of textiles, papermaking, papermaking, coating, etc., can solve the problems of poor adhesion, short-term bronzing UV varnish, and bronzing defects, so as to achieve no bronzing defects and improve light curing efficiency , to meet the effect of bronzing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention also provides the preparation method of the bronzing UV varnish described in the above technical scheme, comprising the following steps:

[0066] Under heating conditions, the photosensitizer, photocrosslinking agent, amine co-initiator and leveling agent are stirred and refluxed and cooled in sequence to obtain the bronzing UV varnish.

[0067] In the present invention, the stirring and refluxing process is preferably to melt the photosensitizer in the range of 90-95° C., then mix it with the photocrosslinking agent, amine co-initiator and leveling agent, and then carry out stirring and refluxing.

[0068] In the present invention, the photosensitizer is melted in the range of 90-95°C, and then mixed with the photocrosslinking agent, amine co-initiator and leveling agent, which can ensure that the photosensitizer does not Coking occurs, ensuring the excellent quality and stability of the bronzable UV varnish product.

[0069] In the present inven...

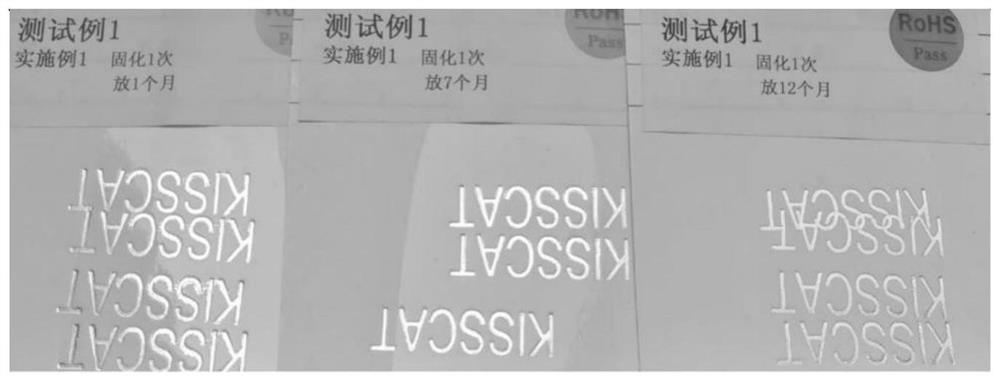

Embodiment 1

[0079] Weigh 30g of hydroxyl acrylic resin, 10g of bisphenol A epoxy diacrylate, 10g of trimethylolpropane triacrylate, 216g of active amine B-216g, 39.7g of tripropylene glycol diacrylate, 0.3g of DC-57 leveling agent, 2,4,6-Trimethylbenzoyl diphenoxyphos 4g;

[0080] Put the raw materials into the reaction kettle, heat to 120°C, stir and reflux, control the stirring speed to 800r / min, and stir for 2h, cool to 40°C and discharge to obtain bronzing UV varnish.

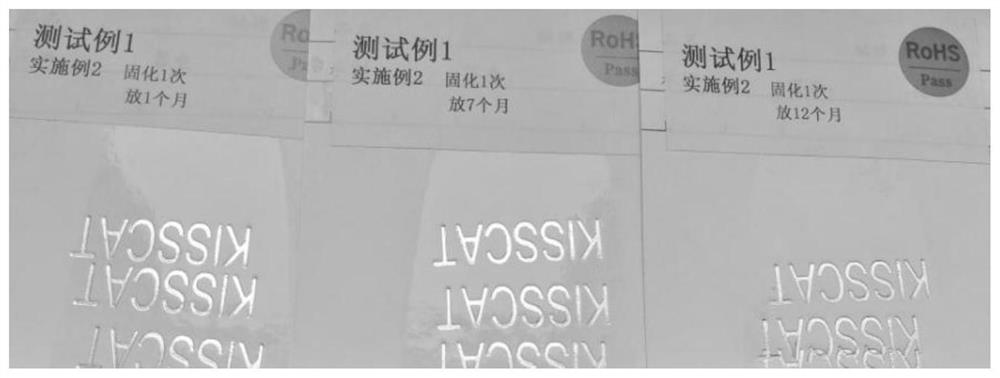

Embodiment 2

[0082] Weigh 30g of hydroxyl acrylic resin, 10g of bisphenol A epoxy diacrylate, 10g of trimethylolpropane triacrylate, 216g of active amine B-216g, 39.7g of tripropylene glycol diacrylate, 0.3g of DC-57 leveling agent, 2,4,6-Trimethylbenzoyl diphenoxyphos 5g;

[0083] Put the raw materials into the reaction kettle, heat to 125°C, stir and reflux, control the stirring speed to 800r / min, and stir for 3h, cool to 40°C and discharge to obtain bronzing UV varnish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com