Preparation method of silica-coated all-inorganic perovskite core-shell structure quantum dots

A silicon dioxide, core-shell structure technology, applied in chemical instruments and methods, luminescent materials, nanotechnology, etc., can solve problems such as optical parameter discount, and achieve the effects of short synthesis cycle, high quantum efficiency, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The raw material purity used in this embodiment is as follows:

[0032] Cesium carbonate (99%), n-octanoic acid (99%), lead bromide (99%), tetra-n-octylammonium bromide (98%), toluene (99%), n-hexane (97%) and APTES (3 - aminopropyltriethoxysilane, 99%).

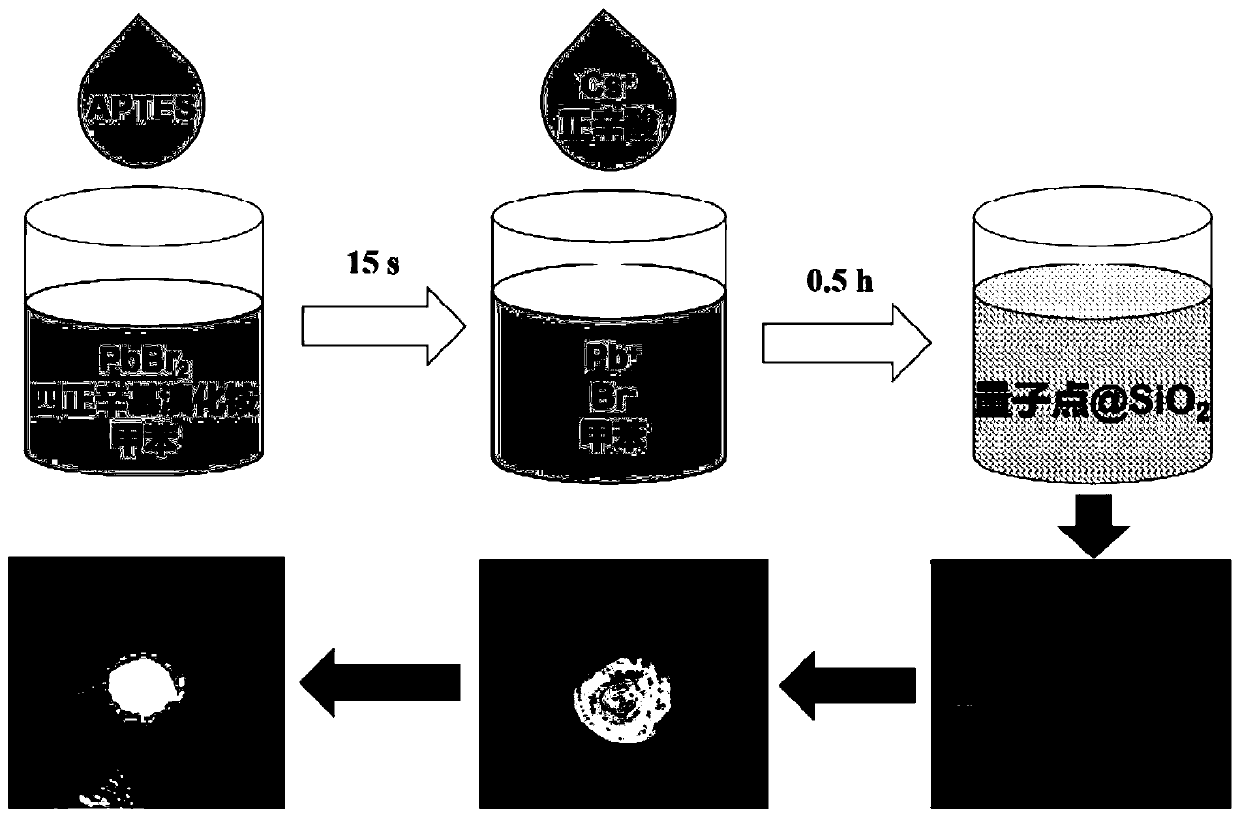

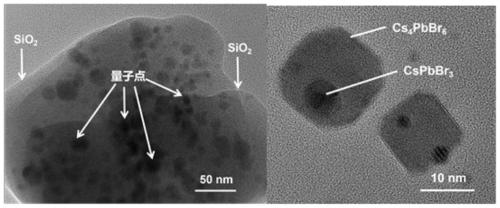

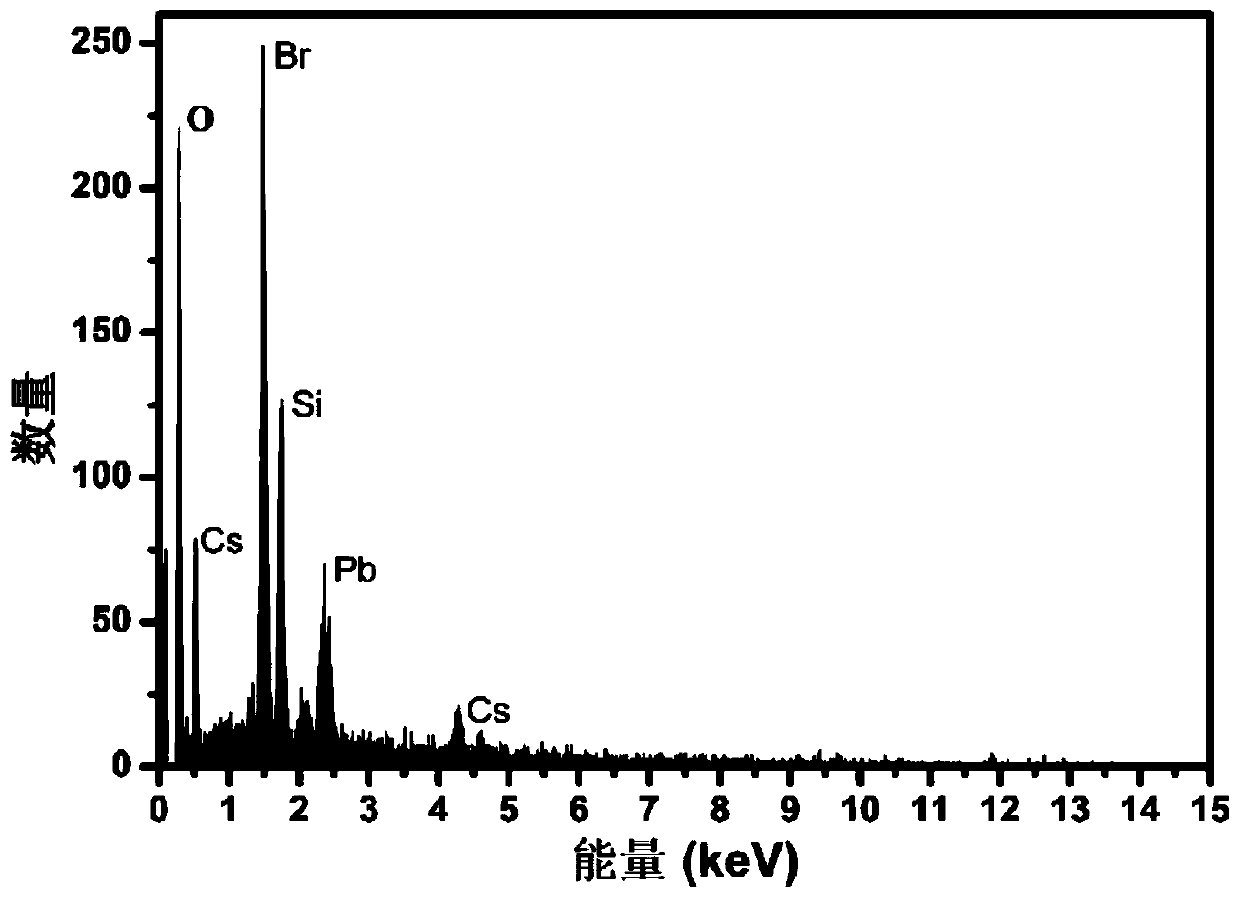

[0033] Press as figure 1 The shown method prepares silica-coated CsPbBr at room temperature 3 / Cs 4 PbBr 6 Core-shell quantum dots.

[0034] Step 1): Inject 0.326g (1mmol) of cesium carbonate into 5ml of n-octanoic acid, and stir at room temperature for 15min to obtain a cesium precursor solution.

[0035] Step 2): 0.367g (1mmol) of lead bromide and 1.094g (2mmol) of tetraoctylammonium bromide were simultaneously added to 3ml of toluene, and magnetically stirred for 20min to obtain a lead bromide / toluene solution.

[0036] Step 3): Rapidly inject 0.7ml APTES into the lead bromide / toluene solution in step 2), and stir magnetically for 15s.

[0037] Step 4): quickly inject the cesium precursor solution in step 1)...

Embodiment 2- Embodiment 4

[0060] Compared with Example 1, most of them are the same, except that the aminosilane coupling agent used in this example is replaced by 3-aminopropyltrimethoxysilane, 3-aminopropylmethyldimethoxysilane or 3-(2-Aminoethylamino)propylmethyldimethoxysilane

Embodiment 5- Embodiment 6

[0062] Compared with Example 1, most of them are the same, except that the stirring time in step 3) of this example is 5s or 30s respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com