Method for producing polyhydroxyalkanoates by using acetic acid or butyric acid

A technology of polyhydroxyalkanoate and acetic acid, applied in the field of biochemistry, can solve the problems of restricting large-scale industrial production and application, high production cost of PHA, etc., achieves good industrial application prospects, reduces fermentation costs, and has great economic advantages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1, utilize acetic acid to produce polyhydroxyalkanoate (shaking flask culture) with Neptunomonas

[0073] 1. Production of polyhydroxyalkanoate from acetic acid by Neptunonas bacterium

[0074] 1. Aseptically prepare Neptunonas seed solution

[0075] (1) Activation of bacteria

[0076] Take a glycerol tube of strains stored in a -80°C refrigerator, streak and inoculate it on a TYS medium plate, and incubate at 37°C for 12-24h.

[0077] (2) First-class seeds

[0078] Pick a single colony from the plate that has completed step (1), inoculate it in liquid TYS medium, and cultivate it at 37° C. with shaking at 200 rpm for 10-12 hours.

[0079] (3)Secondary seed

[0080] Take the primary seed liquid obtained in step (2), inoculate it in liquid TYS medium according to the inoculum amount of 1%, add 10 g / L acetic acid as carbon source, and culture at 37°C and 200 rpm for 10-12 hours with shaking.

[0081] 2. Prepare liquid TYS medium, add acetic acid to a final...

Embodiment 2

[0101] Embodiment 2, utilize butyric acid to produce polyhydroxyalkanoate (shake flask culture) with Neptunomonas

[0102] 1. Production of polyhydroxyalkanoate from butyric acid by Neptunomonas

[0103] 1. Aseptically prepare Neptunonas seed solution

[0104] (1) Activation of bacteria

[0105] Take a glycerol tube of strains stored in a -80°C refrigerator, streak and inoculate it on a TYS medium plate, and incubate at 37°C for 12-24h.

[0106] (2) First-class seeds

[0107] Pick a single colony from the plate that has completed step (1), inoculate it in liquid TYS medium, and cultivate it at 37° C. with shaking at 200 rpm for 10-12 hours.

[0108] (3)Secondary seed

[0109]Take the primary seed liquid obtained in step (2), inoculate it in liquid TYS medium according to the inoculum amount of 1%, add 10 g / L butyric acid as a carbon source, and culture at 37°C and 200 rpm for 10-12 hours with shaking.

[0110] 2. Prepare liquid TYS medium, add butyric acid to a final conc...

Embodiment 3

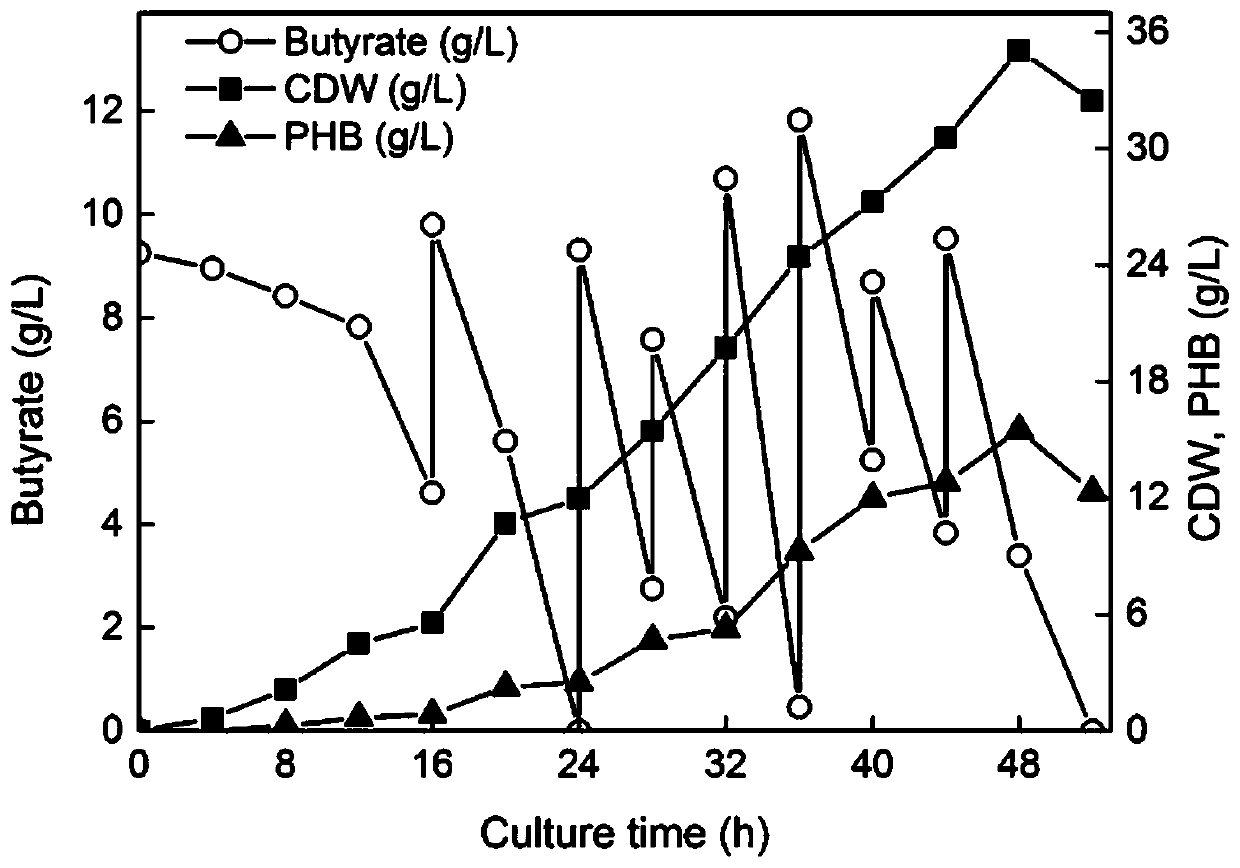

[0121] Embodiment 3, utilize butyric acid to produce polyhydroxyalkanoate (fermenter cultivation) with Neptunomonas

[0122] 1. Production of polyhydroxyalkanoate from butyric acid by Neptunomonas

[0123] 1. Aseptically prepare Neptunonas seed solution

[0124] (1) Activation of bacteria

[0125] Take a glycerol tube of strains stored in a -80°C refrigerator, streak and inoculate it on a TYS medium plate, and incubate at 37°C for 12-24h.

[0126] (2) First-class seeds

[0127] Pick a single colony from the plate that has completed step (1), inoculate it in liquid TYS medium, and cultivate it at 37° C. with shaking at 200 rpm for 10-12 hours.

[0128] (3)Secondary seed

[0129] Take the primary seed liquid obtained in step (2), inoculate it in liquid TYS medium according to the inoculum amount of 1%, add 10 g / L butyric acid as a carbon source, and culture at 37°C and 200 rpm for 10-12 hours with shaking. A total of 300ml of secondary seed liquid is required for fermenter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com