Ignition gas distribution ring for arc plasma torch

An arc plasma and gas distribution technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of limiting diamond quality and further improvement of performance, etc., to achieve lower temperature, simple structure, prevent deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

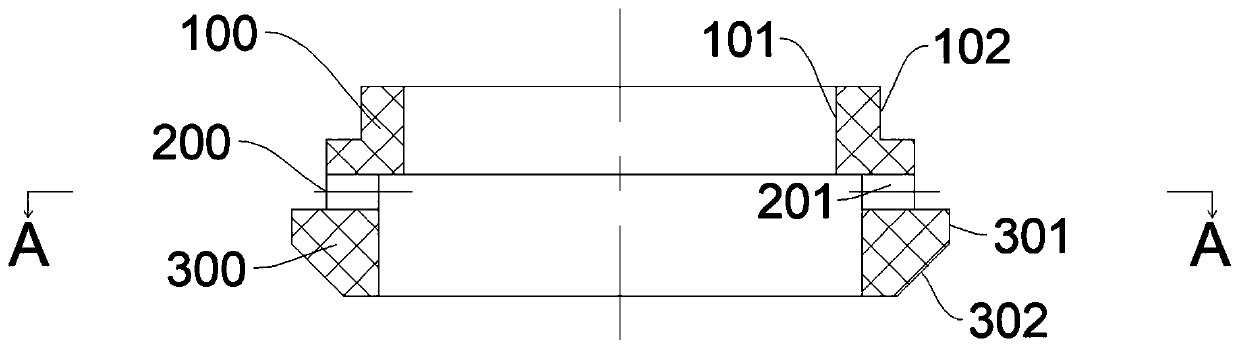

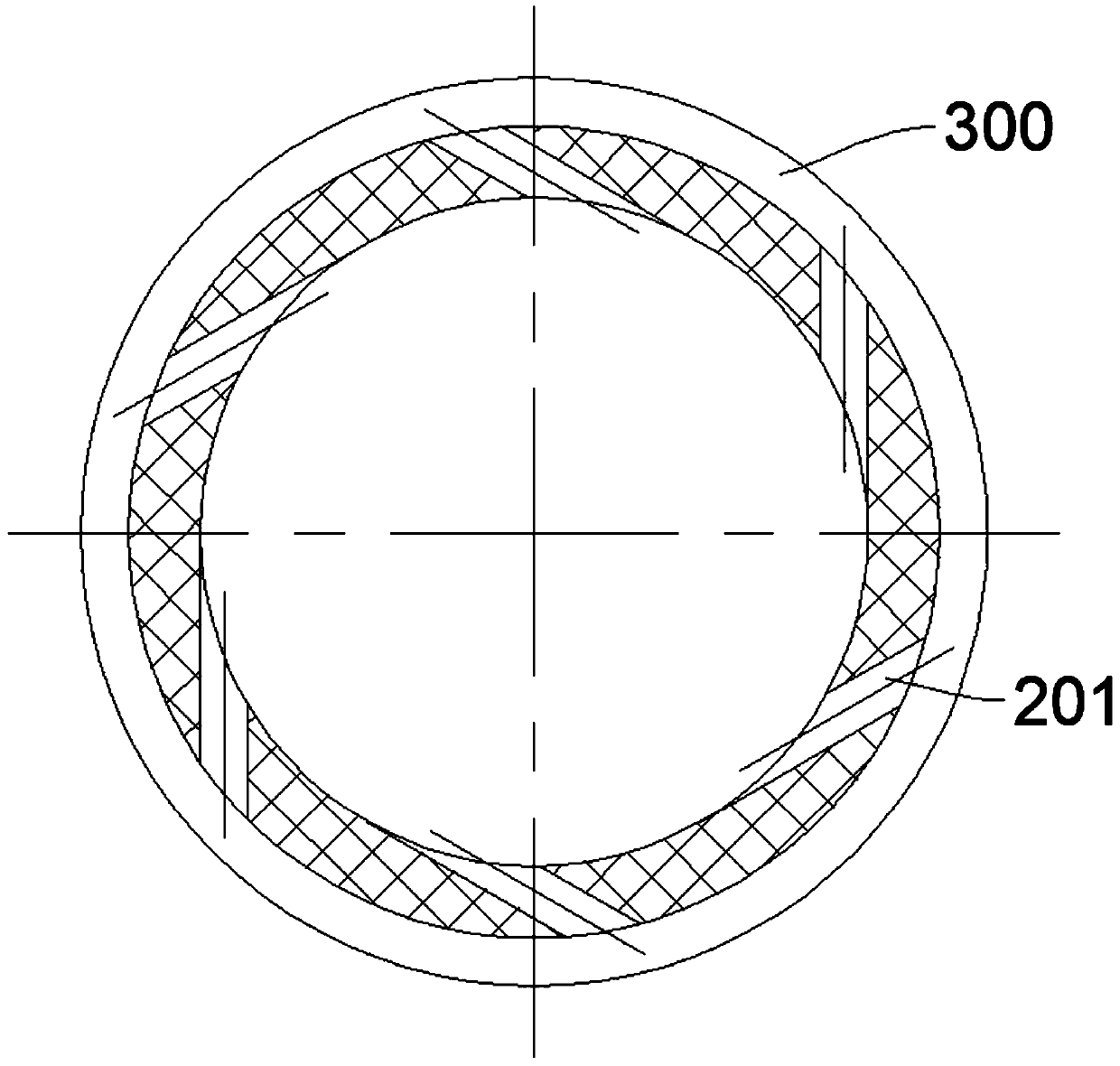

[0032] Embodiment 1 adopts Figure 1-2 The distribution ring structure, the installation method is as follows Figure 5 shown. The cathode 5 is made of tungsten rod, the first anode 7 is made of copper, the gas distribution ring with an outer diameter of 42 mm is arranged on the same plane, and six tangential holes 201 with a diameter of 1.5 mm are evenly and symmetrically arranged, and the ignition gas is a protective Gas argon, the flow rate of argon is 2.5 liters per minute, the main gas is composed of argon, hydrogen and LPG and other gases, the working voltage is 110V, the current is 165A, and the voltage has been stable at 110V+ / -0.5V during the continuous operation of 250 hours , as shown in Table 1, indicating that the cathode working state is very stable throughout the process. Figure 6 It is the Raman spectrum of diamond produced by this deposition equipment, only 1332cm -1 The sharp diamond peak at the position shows that there is no metal impurity in the diamon...

Embodiment 2

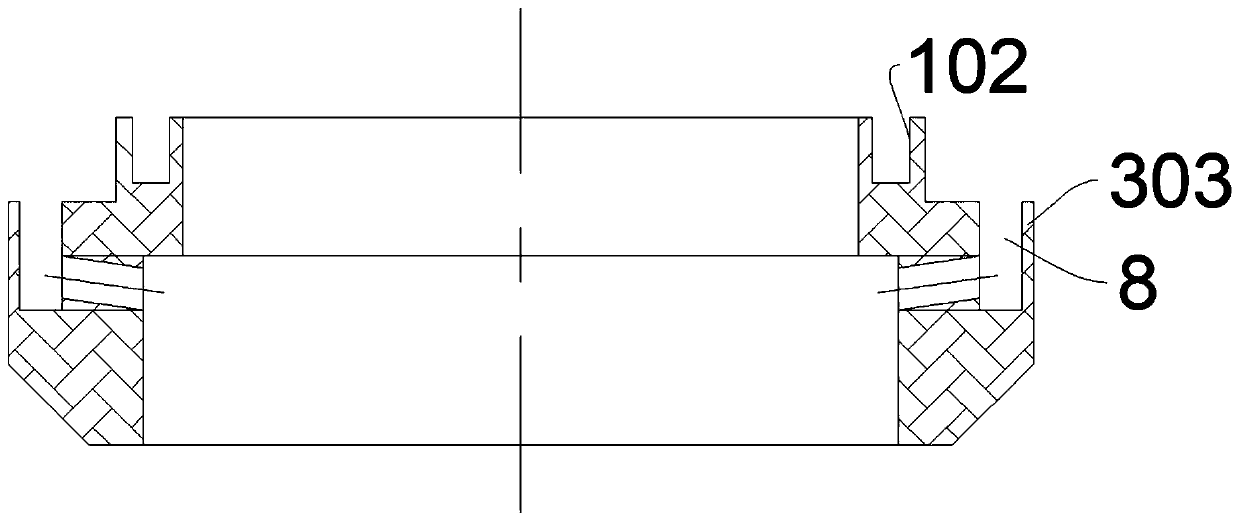

[0033] Embodiment 2 adopts the same parameter conditions as Embodiment 1, wherein the channel of the tangential hole of the distribution ring is arranged obliquely along the tangential direction, that is, the axis of the channel of the tangential hole and the axis of the ring body of the distribution ring form an included angle of 75°. During 250 hours of continuous operation, the voltage has been stable at 110V+ / -0.3V, and the voltage stability has been further improved, which is more conducive to arc stability and electrode life, and avoids metal evaporation and diamond pollution.

[0034] Table 1 Voltage values at different time points during diamond production

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com