RC-IGBT chip and manufacturing method thereof

A manufacturing method and chip technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that the reverse recovery characteristics of diodes cannot be fully reduced, and achieve the effect of good reverse recovery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

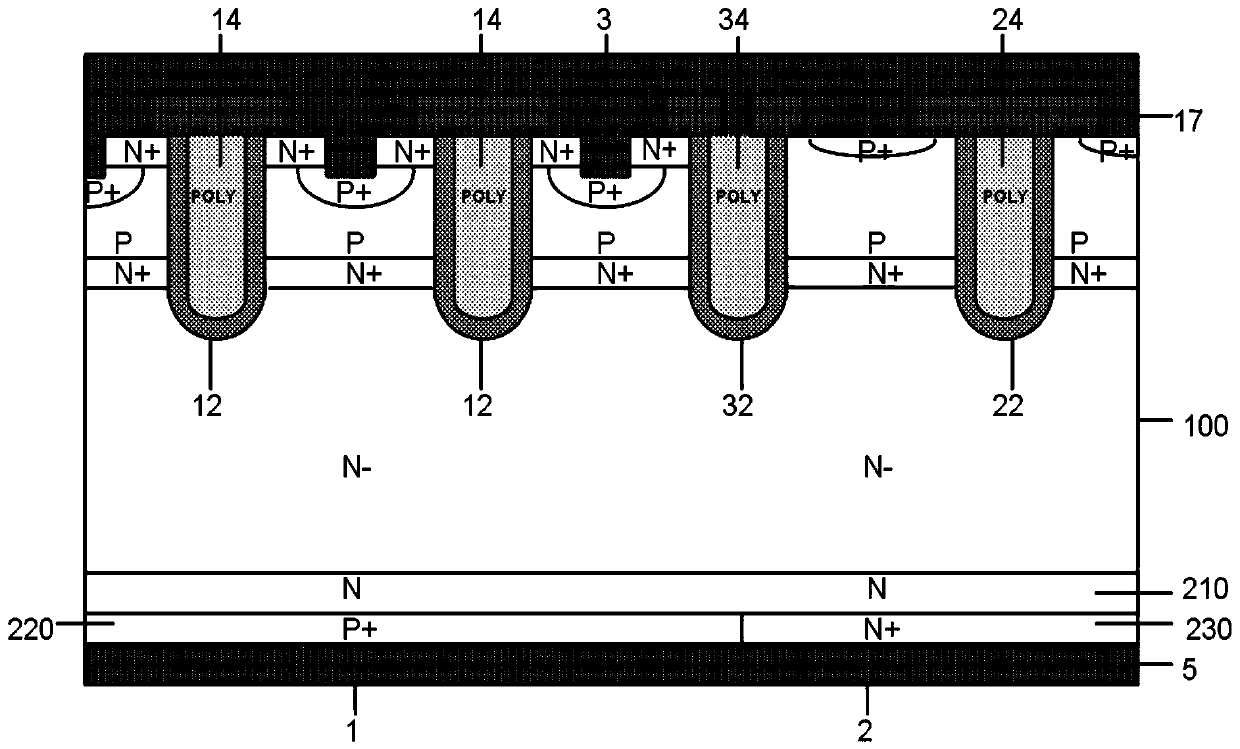

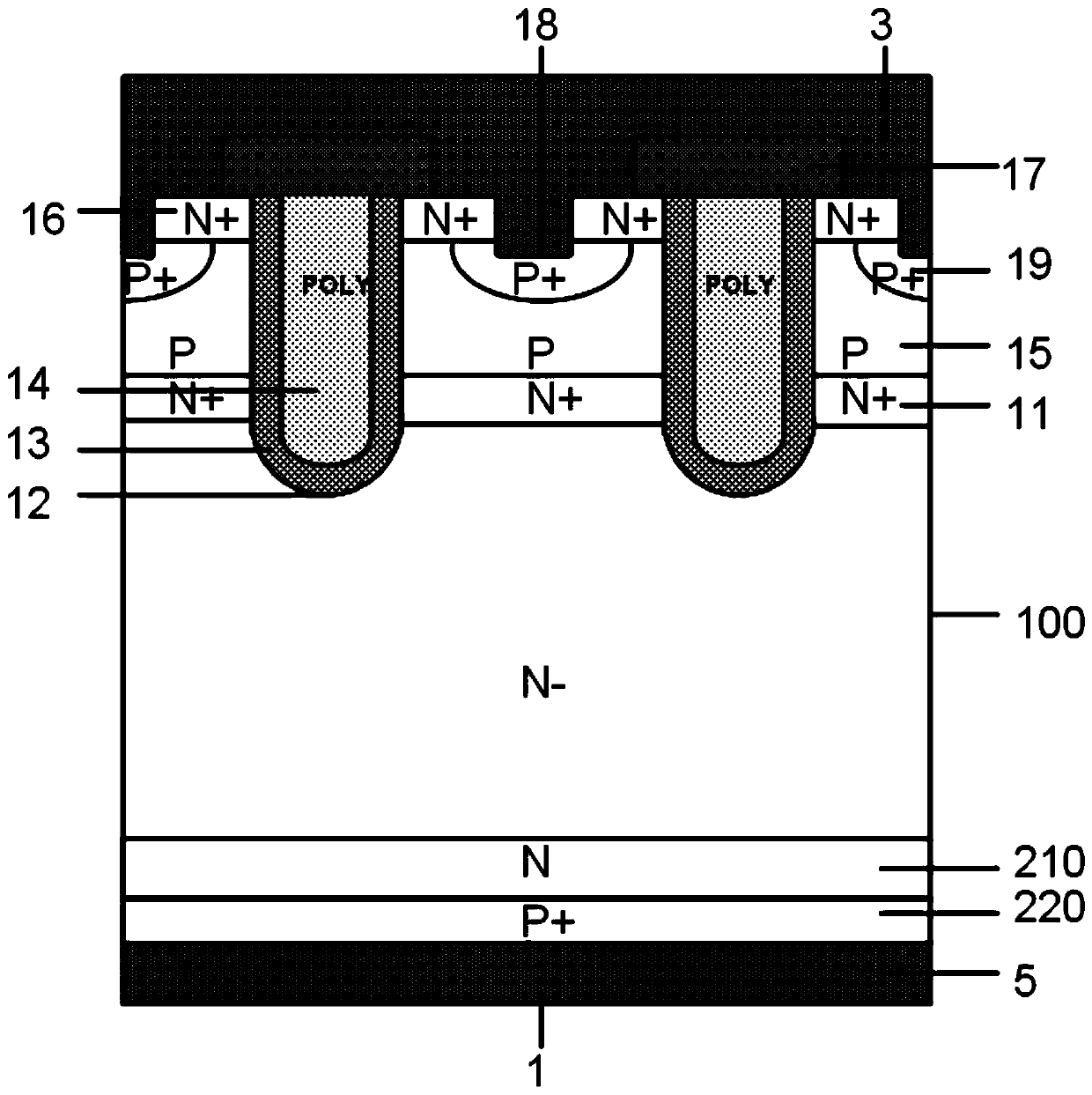

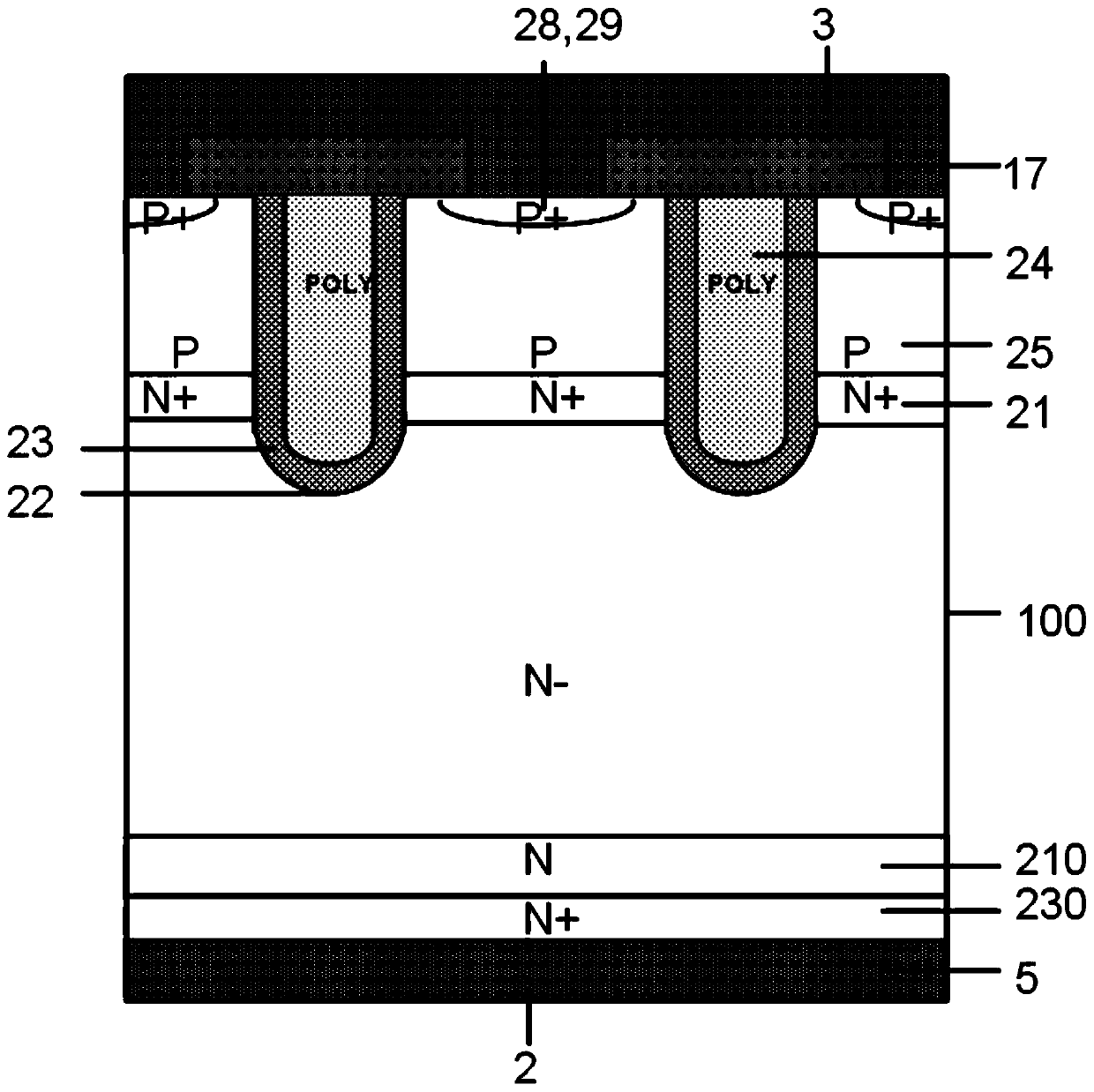

[0031] see Figure 1 to Figure 3, the RC-IGBT chip of a preferred embodiment of the present invention includes an IGBT region and an FRD region, and both the IGBT region and the FRD region include an N-type drift region formed by a semiconductor substrate 100, an N-type field stop located on the back of the N-type drift region region 210 and the collector 5 located below the N-type field termination region, a P-type collector region 220 is provided between the N-type field termination region and the collector in the IGBT region, and a P-type collector region 220 is provided between the N-type field termination region and the collector in the FRD region. An N-type collecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com