Composite neutron target suitable for BNCT system

A neutron and target layer technology, used in X-ray/γ-ray/particle irradiation therapy, electrical components, DC voltage accelerators, etc. The problem of poor heat dissipation effect of sub-targets can reduce the interface effect, shorten the treatment time and avoid normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

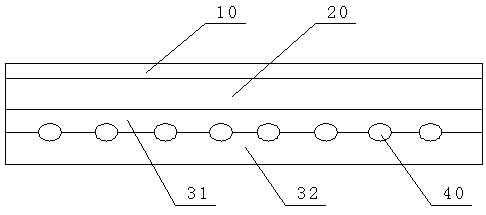

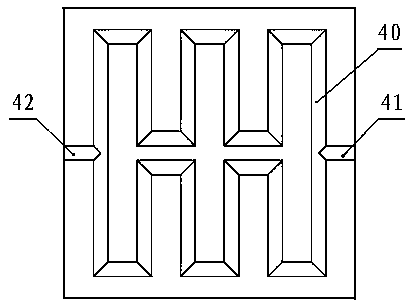

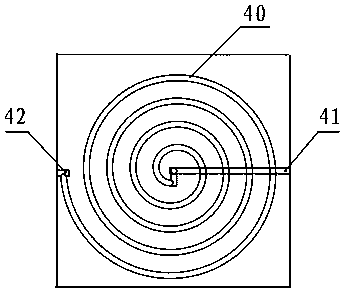

[0035] see Figure 1-5, this kind of neutron target adopts a "sandwich" structure. The target plate includes a tantalum target layer 10, a beryllium target layer 20 and a heat dissipation base layer distributed in sequence. The tantalum target layer is in front, and the heat dissipation base layer is behind. Between the heat dissipation base layers, the tantalum target layer is made of metal tantalum and / or tantalum alloy, and is located at the front of the target plate, and the beryllium target layer is made of metal beryllium and / or beryllium alloy, and is located on the tantalum target layer Between the heat dissipation base layer and the heat dissipation base layer, the heat dissipation base layer is located at the rear of the target plate, and a coolant flow channel 40 is provided inside the heat dissipation base layer and / or between the heat dissipation base layer and the beryllium target layer, and the coolant The flow channel is provided with inlet and outlet ports 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com