Sterilization method for fresh-kept wet rice noodles

A sterilization method and technology for wet rice flour, applied in the field of food processing, can solve the problems of incomplete sterilization and spoilage of rice flour, and achieve the effects of rapid and thorough sterilization, reducing decomposition and avoiding easy residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation process of fresh-keeping wet rice noodles is carried out as follows:

[0029] (1) After the early indica rice is washed, soaked, refined and slurried, it is extruded and dispersed by a full-automatic rice flour machine;

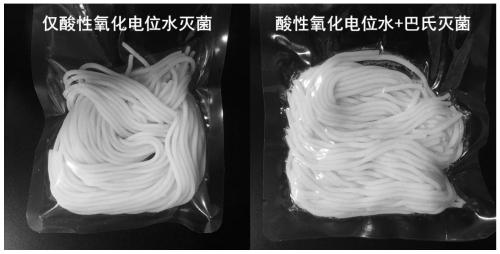

[0030] (2) take the mode of closed soaking and utilize acidic oxidation potential water to sterilize the fresh wet rice noodles scattered;

[0031] (3) After drying the fresh and wet rice noodles obtained in (2) in a sterile or clean environment, put them into a retort pouch for heat-sealed packaging.

[0032] Among them, the early indica rice was soaked at 25°C for 48 hours, the mass ratio of dry rice to water was 1.35:1 when refining, the mass ratio of dry rice to cornstarch was 10:1 when pulping, and the extrusion temperature was 108°C; The pH of the oxidation potential water is 3, the soaking time is 6 minutes, stored at 28°C, and the shelf life can reach 15-20 days.

Embodiment 2

[0034] The preparation process of fresh-keeping wet rice noodles is carried out as follows:

[0035] (1) After the early indica rice is washed, soaked, refined and slurried, it is extruded and dispersed by a full-automatic rice flour machine;

[0036] (2) take the mode of closed soaking and utilize acidic oxidation potential water to sterilize the fresh wet rice noodles scattered;

[0037] (3) After drying the fresh and wet rice noodles obtained in (2) in a sterile or clean environment, put them into a retort pouch for heat-sealed packaging.

[0038] Among them, the early indica rice was soaked at 20°C for 4 days, the mass ratio of dry rice to water was 1:1 when refining, the mass ratio of dry rice to cornstarch was 10:1 when pulping, and the extrusion temperature was 100°C. The pH of the acidic oxidation potential water is 4, the soaking time is 8 minutes, the pasteurization condition is 70°C water bath sterilization for 20 minutes, the obtained fresh wet rice noodles are st...

Embodiment 3

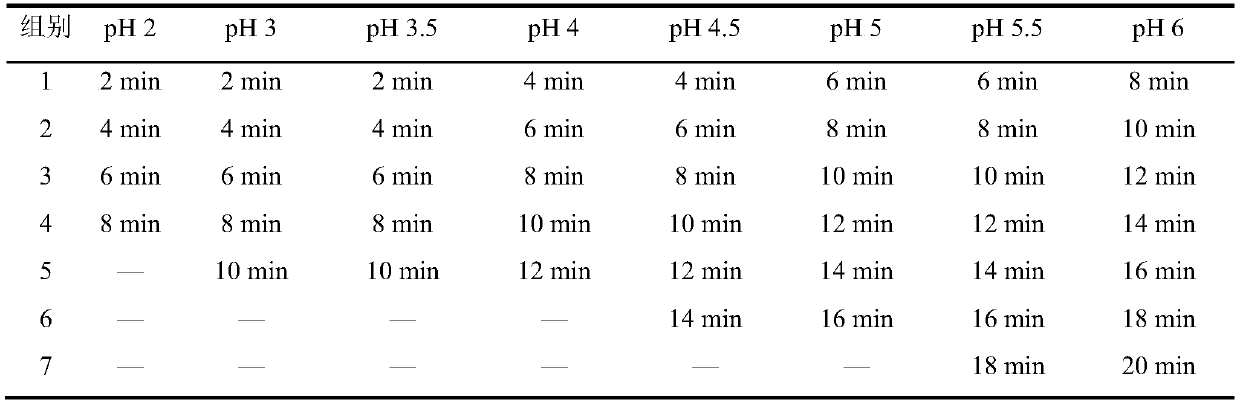

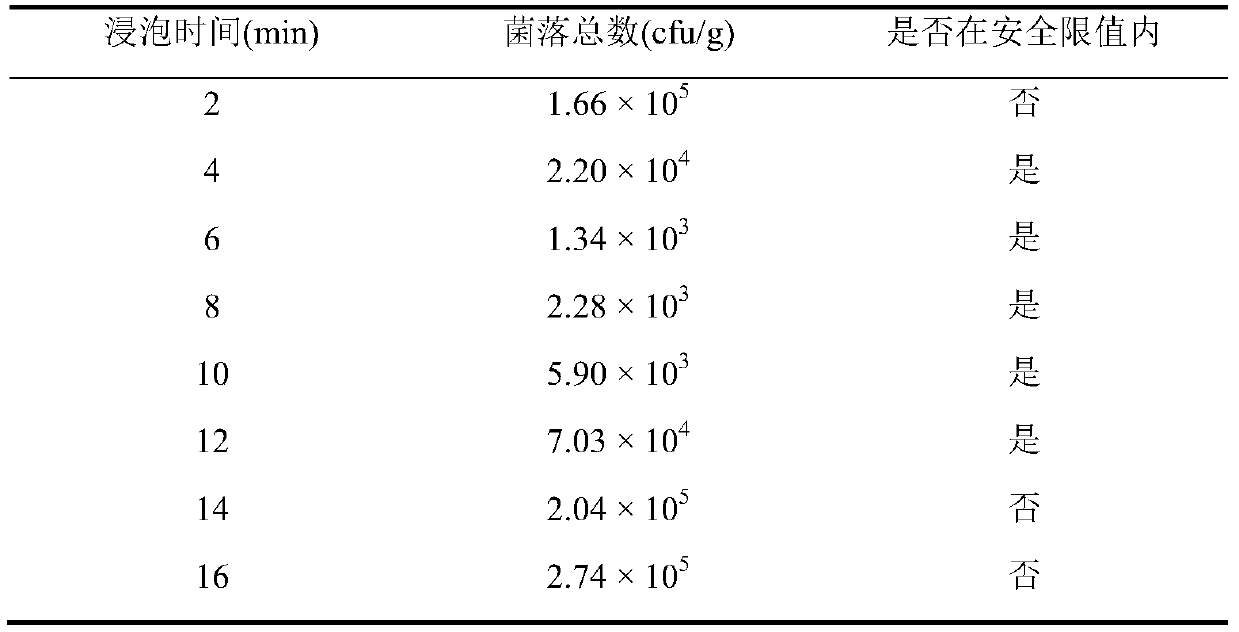

[0039] Embodiment 3: the influence of acid oxidation potential water sterilization condition on the shelf life (28 ℃) of fresh-keeping wet rice noodles

[0040] The preparation process of fresh-keeping wet rice noodles is carried out as follows:

[0041] (1) After the early indica rice is washed, soaked, refined and slurried, it is extruded and dispersed by a full-automatic rice flour machine;

[0042] (2) take the mode of closed soaking and utilize acidic oxidation potential water to sterilize the fresh wet rice noodles scattered;

[0043] (3) After drying the fresh and wet rice noodles obtained in (2) in a sterile or clean environment, put them into a retort pouch for heat-sealed packaging.

[0044]Among them, the early indica rice was soaked at 25°C for 48 hours, the mass ratio of dry rice to water was 1.35:1 during pulping, the mass ratio of dry rice to cornstarch was 10:1 during pulping, and the extrusion temperature was 108°C. The pH and immersion time of the acidic ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com