Polyoxysilane and preparation method thereof, and glass protection composition and use thereof

A composition, polysiloxane technology, applied in coatings, fire-retardant coatings, etc., can solve problems such as difficult glass protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

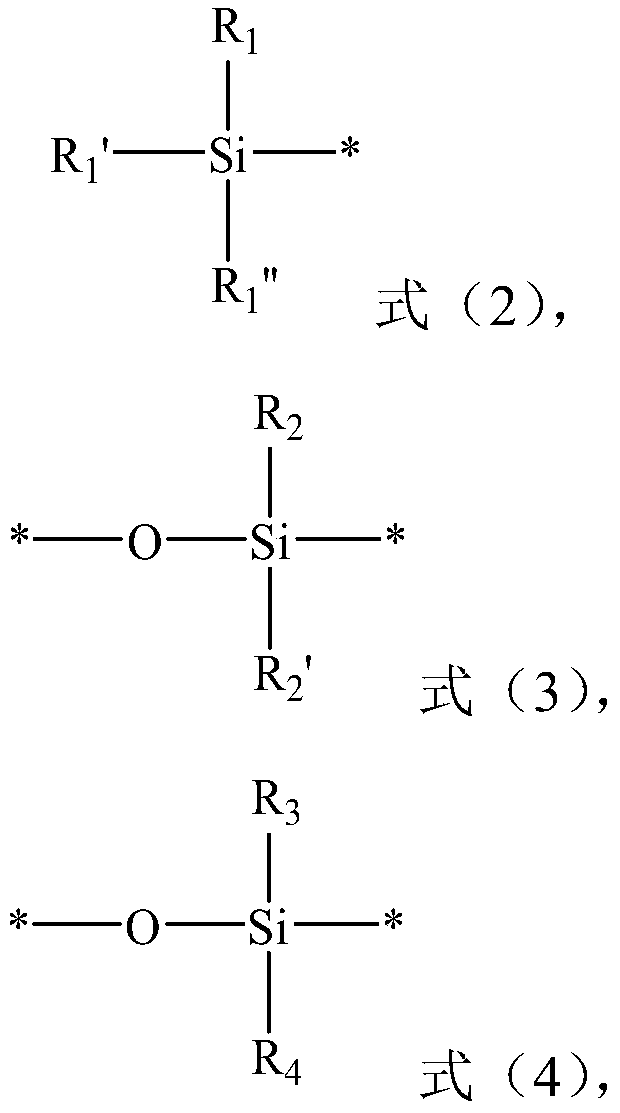

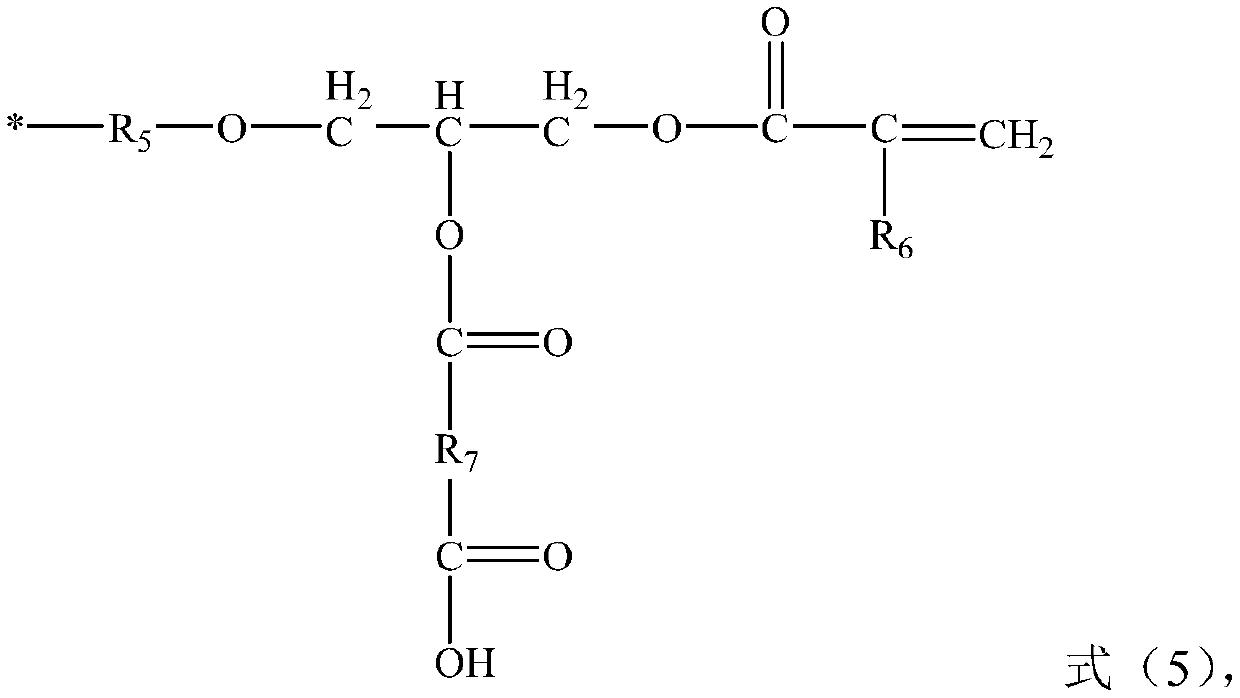

Method used

Image

Examples

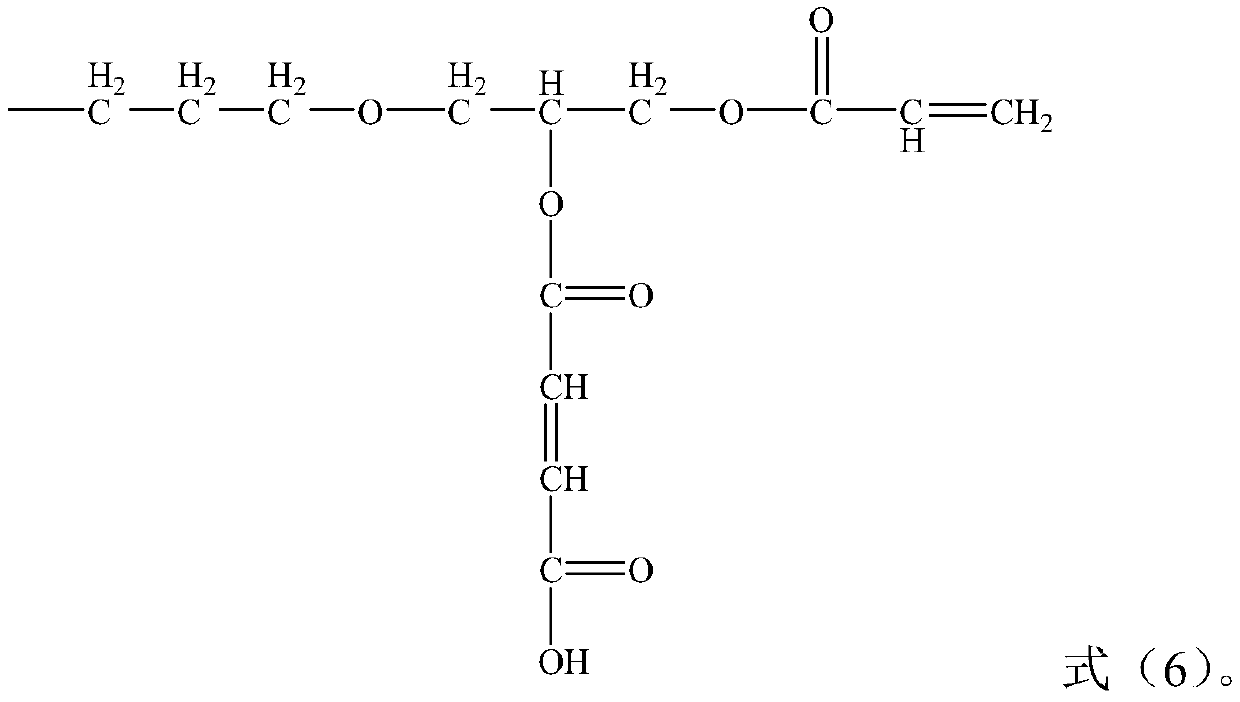

preparation Embodiment 1

[0115] In a 250mL three-necked flask with a reflux condenser, a stirrer and a thermometer, add 50g (0.4167mol) of dimethyldimethoxysilane, 40g (0.1639mol) of diphenyldimethoxysiloxane, and 11.4959g ( 0.6387mol) and 0.5040g of phosphoric acid catalyst of 10% by weight, N 2 Under protection, start to stir slowly, raise the temperature to 80°C; keep warm for 2h; add 17.5102g of γ-glycidyl etheroxypropylmethyldiethoxysilane dropwise at a rate of 3mL / min, keep warm at 80°C for 5h, then Add 0.8497 g of triphenylmethoxysiloxane and keep it warm for 1 hour to obtain the first intermediate product. The molar ratio of the first monomer, the second monomer and the third monomer is 1:0.01:0.005.

[0116]When the temperature reaches the reaction temperature of 70°C, slowly dropwise add 2.0919g of acrylic acid, 0.36g of hydroquinone as a polymerization inhibitor and N,N-dimethylaniline as a catalyst to the above-mentioned first intermediate product at a rate of 3.5mL / min. 0.9 g of the mix...

preparation Embodiment 2

[0119] In a 250mL three-necked flask with reflux condenser, stirrer and thermometer, add dimethyldimethoxysilane 40g (0.3333mol) and diphenyldimethoxysiloxane 60g (0.2459mol), water 10.4262g and 10% by weight phosphoric acid catalyst 1.22g, N 2 Under protection, start to stir slowly, raise the temperature to 90°C; keep warm for 12h; add 28.7764g of γ-glycidyl etheroxypropylmethyldiethoxysilane dropwise at a rate of 2.5mL / min, keep warm at 90°C for 6h, Then 1.6954 g of triphenylmethoxysiloxane was added and kept for 1 hour to obtain the first intermediate product. The molar ratio of the first monomer, the second monomer and the third monomer is 1:0.2:0.01.

[0120] When the temperature reaches the reaction temperature of 80°C, slowly dropwise add 10.0175g of acrylic acid, 0.8g of hydroquinone as a polymerization inhibitor and N,N-dimethylaniline as a catalyst to the above-mentioned first intermediate product at a rate of 2.5mL / min. 2 g of the reaction mixture was formed. Slo...

preparation Embodiment 3

[0123] In a 250mL three-necked flask with a reflux condenser, a stirrer and a thermometer, add 50g (0.4167mol) of dimethyldimethoxysilane, 50g (0.2049mol) of diphenyldimethoxysiloxane, and 13.4262g of water ( 0.74592mol) and 10% by weight of phosphoric acid catalyst 2g, N 2 Under protection, start to stir slowly, raise the temperature to 80°C; keep warm for 2h; add 1.5440g of γ-glycidyl etheroxypropylmethyldiethoxysilane dropwise at a rate of 4mL / min, and the dropping time is 15min. Insulate at 80°C for 1 hour, then add 36.3876 g of triphenylmethoxysiloxane, and incubate for 1 hour to obtain the first intermediate product. γ The molar ratio of the first monomer, the second monomer and the third monomer is 1:0.01:0.2.

[0124] When the temperature reaches the reaction temperature of 70°C, slowly add 0.6719 g of acrylic acid, 1 g of inhibitor hydroquinone and 0.1 g of catalyst N,N-dimethylaniline dropwise at a rate of 40 mL / min to the above-mentioned first intermediate product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com