Polyoxysilane and its preparation method, glass protection composition and its application

A technology of composition and polysiloxane, applied in the direction of coating, fireproof coating, etc., can solve the problems of difficult glass protection, and achieve the effect of easy removal and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

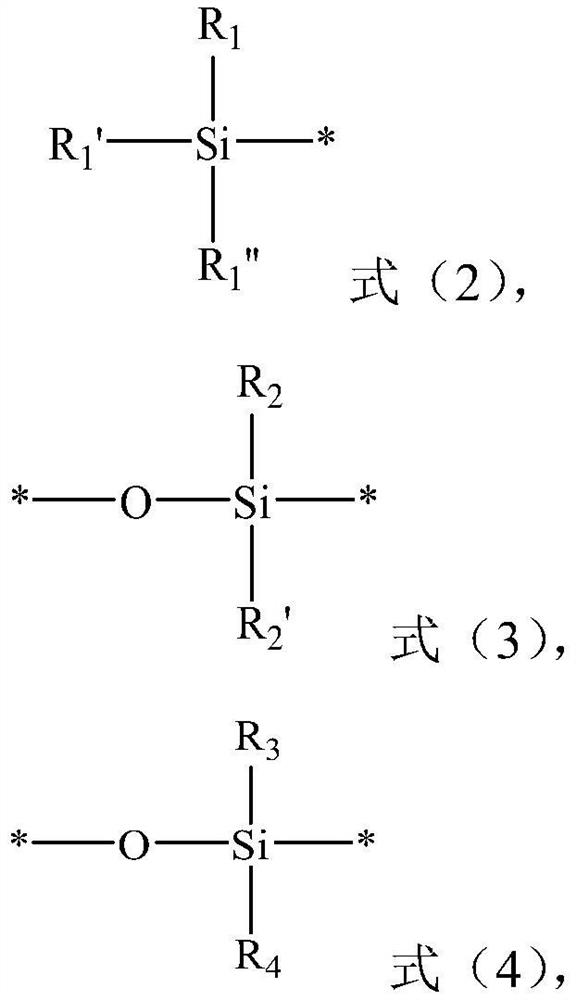

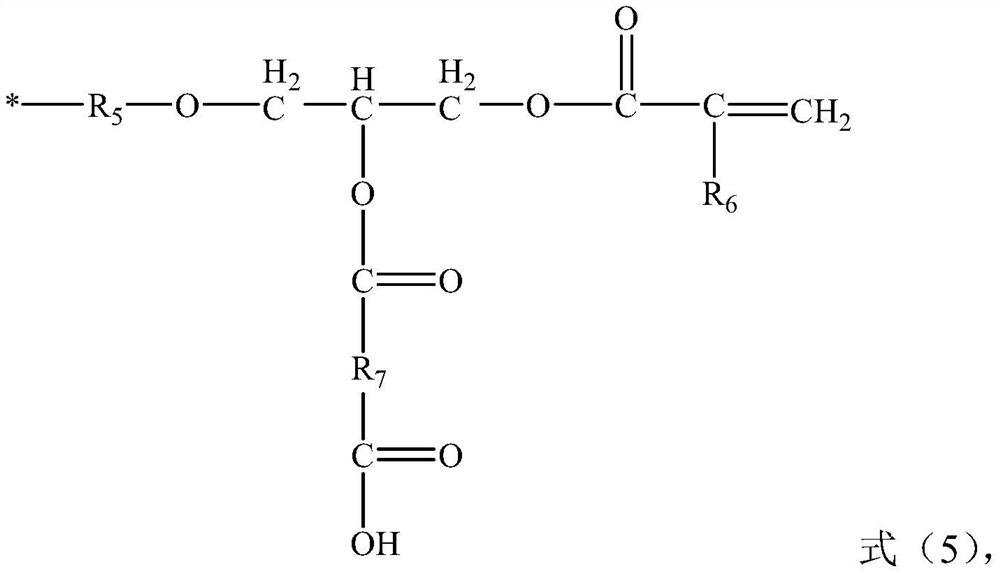

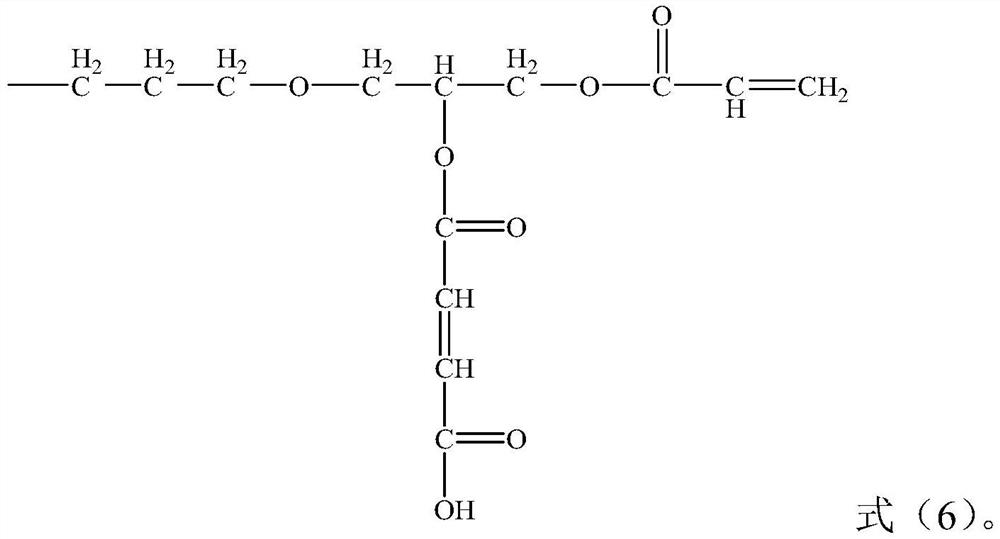

Method used

Image

Examples

preparation Embodiment 1

[0115] In a 250mL three-necked flask with a reflux condenser, a stirrer and a thermometer, add 50g (0.4167mol) of dimethyldimethoxysilane, 40g (0.1639mol) of diphenyldimethoxysiloxane, and 11.4959g ( 0.6387mol) and 0.5040g of phosphoric acid catalyst of 10% by weight, N 2 Under protection, start to stir slowly, raise the temperature to 80°C; keep warm for 2h; add 17.5102g of γ-glycidyl etheroxypropylmethyldiethoxysilane dropwise at a rate of 3mL / min, keep warm at 80°C for 5h, then Add 0.8497 g of triphenylmethoxysiloxane and keep it warm for 1 hour to obtain the first intermediate product. The molar ratio of the first monomer, the second monomer and the third monomer is 1:0.01:0.005.

[0116]When the temperature reaches the reaction temperature of 70°C, slowly dropwise add 2.0919g of acrylic acid, 0.36g of hydroquinone as a polymerization inhibitor and N,N-dimethylaniline as a catalyst to the above-mentioned first intermediate product at a rate of 3.5mL / min. 0.9 g of the mix...

preparation Embodiment 2

[0119] In a 250mL three-necked flask with reflux condenser, stirrer and thermometer, add dimethyldimethoxysilane 40g (0.3333mol) and diphenyldimethoxysiloxane 60g (0.2459mol), water 10.4262g and 10% by weight phosphoric acid catalyst 1.22g, N 2 Under protection, start to stir slowly, raise the temperature to 90°C; keep warm for 12h; add 28.7764g of γ-glycidyl etheroxypropylmethyldiethoxysilane dropwise at a rate of 2.5mL / min, keep warm at 90°C for 6h, Then 1.6954 g of triphenylmethoxysiloxane was added and kept for 1 hour to obtain the first intermediate product. The molar ratio of the first monomer, the second monomer and the third monomer is 1:0.2:0.01.

[0120] When the temperature reaches the reaction temperature of 80°C, slowly dropwise add 10.0175g of acrylic acid, 0.8g of hydroquinone as a polymerization inhibitor and N,N-dimethylaniline as a catalyst to the above-mentioned first intermediate product at a rate of 2.5mL / min. 2 g of the reaction mixture was formed. Slo...

preparation Embodiment 3

[0123] In a 250mL three-necked flask with a reflux condenser, a stirrer and a thermometer, add 50g (0.4167mol) of dimethyldimethoxysilane, 50g (0.2049mol) of diphenyldimethoxysiloxane, and 13.4262g of water ( 0.74592mol) and 10% by weight of phosphoric acid catalyst 2g, N 2 Under protection, start to stir slowly, raise the temperature to 80°C; keep warm for 2h; add 1.5440g of γ-glycidyl etheroxypropylmethyldiethoxysilane dropwise at a rate of 4mL / min, and the dropping time is 15min. Insulate at 80°C for 1 hour, then add 36.3876 g of triphenylmethoxysiloxane, and incubate for 1 hour to obtain the first intermediate product. γ The molar ratio of the first monomer, the second monomer and the third monomer is 1:0.01:0.2.

[0124] When the temperature reaches the reaction temperature of 70°C, slowly add 0.6719 g of acrylic acid, 1 g of inhibitor hydroquinone and 0.1 g of catalyst N,N-dimethylaniline dropwise at a rate of 40 mL / min to the above-mentioned first intermediate product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com