Concave-convex surrounding internal cooling type turbine generator end ventilation cooling system with multiple shields

A turbo-generator, ventilation and cooling technology, applied in the direction of magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problems of lowering temperature and unreasonable ventilation design, saving materials and enhancing long-term safety and stability The ability to run, the effect of enhanced cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

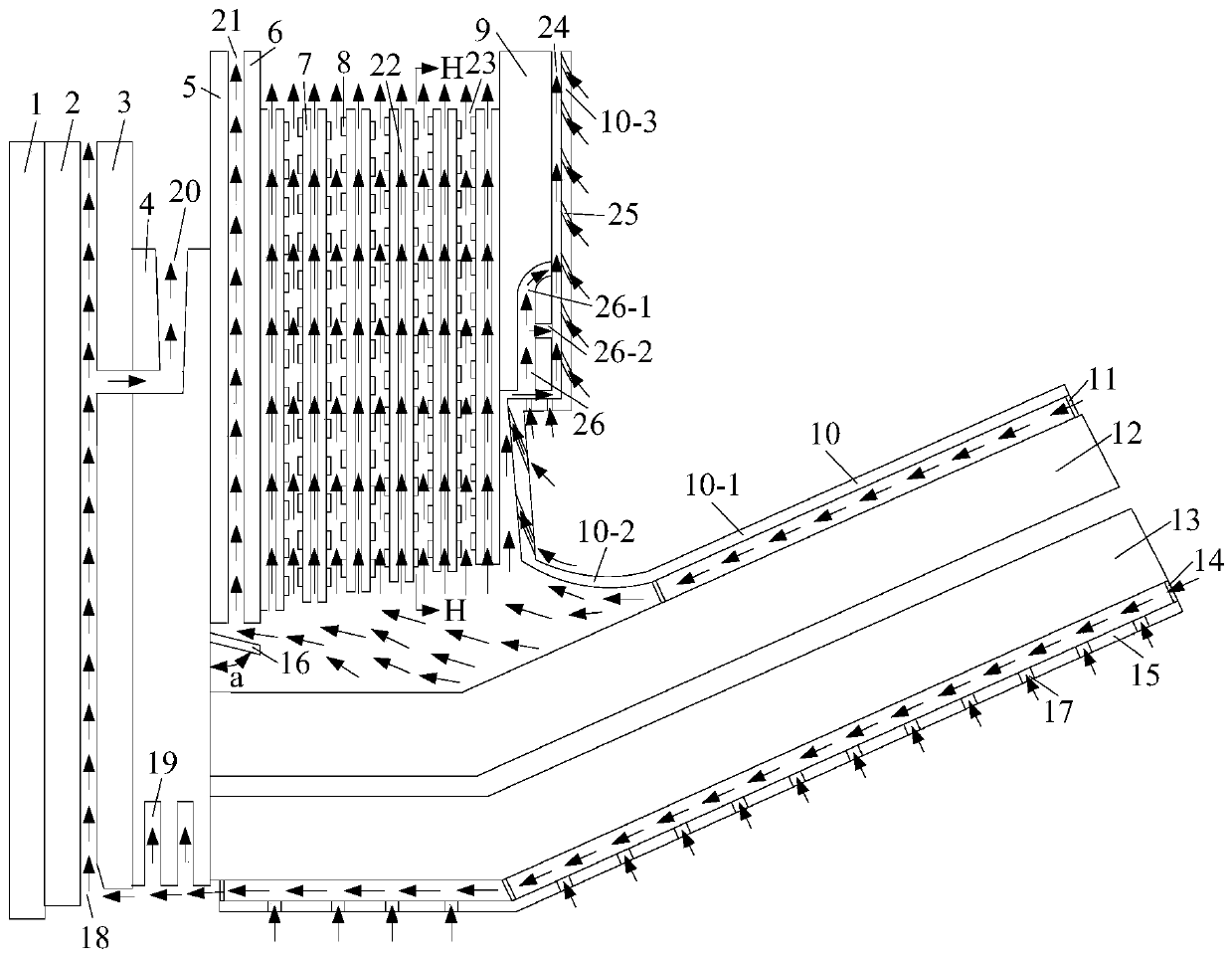

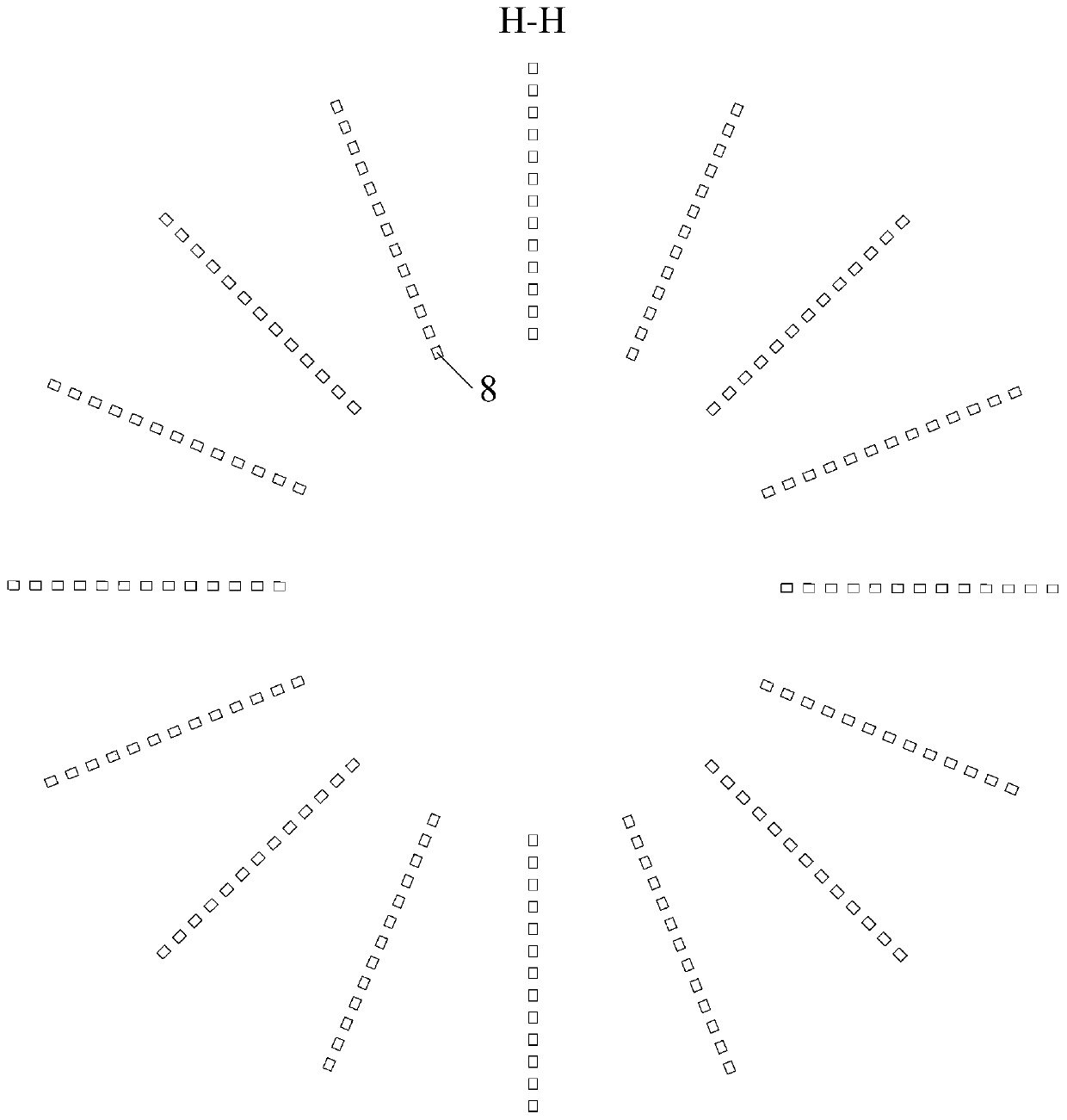

[0021] Specific implementation mode one: combine figure 1 and figure 2Describe this embodiment. The multi-shielding concave-convex surround internal cooling type turbogenerator end ventilation cooling system described in this embodiment includes the end iron core 1 of the second section of the stator, the iron core 1 at the outer end of the first section of the stator Core 2, iron core at the inner end of the first section of the stator 3, self-cooling tooth pressure plate 4, inner lamination ring 5, outer lamination ring 6, concave-convex surrounding magnetic shield 7, heat dissipation teeth 8, self-cooling shield pressure plate 9 , bow-shaped large copper shield 10, upper fixed bracket 11, stator lower end winding 12, stator upper end winding 13, lower fixed bracket 14, bent large copper shield 15, inclined small copper shield 16, bent large Supplementary ventilation channel 17 inside copper shield, radial ventilation groove 18 of iron core at the end of stator, heat dissi...

specific Embodiment approach 2

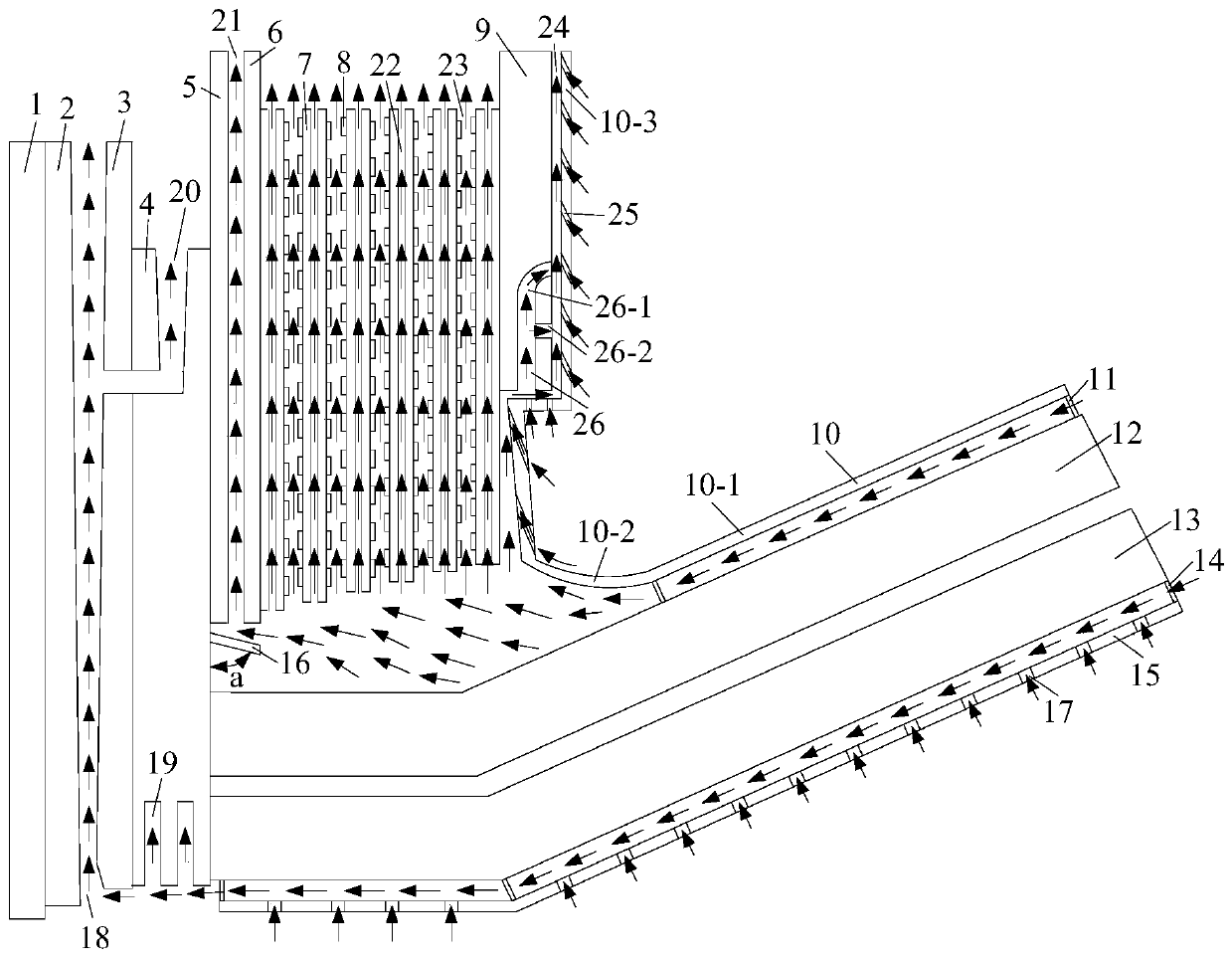

[0024] Specific implementation mode two: combination image 3 Describe this embodiment. The difference between this embodiment and Embodiment 1 is that the outlet area of the iron core radial ventilation groove 18 at the stator end is doubled, which improves the access to the radial ventilation groove 18 of the iron core at the stator end. The flow and velocity of the cooling gas increase the surface heat dissipation coefficient of the first section of the outer end iron core 2 of the stator and the inner end iron core 3 of the first section of the stator, and further reduce the The temperature of the iron core 3 at the inner end of the first section. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination Figure 4 This embodiment is described. The difference between this embodiment and Embodiment 1 is that cooling fins 27 are installed on the arcuate large copper shield 10, which increases the contact area between the cooling gas and the arcuate large copper shield 10, and improves the cooling gas take away. The heat capacity of the bow-shaped large copper shield 10 effectively reduces the temperature of the bow-shaped large copper shield 10 . Other components and connections are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial width | aaaaa | aaaaa |

| Radial height | aaaaa | aaaaa |

| Axial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com