Cr-doped In2S3 intermediate band material and preparation method thereof

A cr-in2s3, intermediate band technology, applied in chemical instruments and methods, gallium/indium/thallium compounds, final product manufacturing, etc., can solve problems such as analysis, discussion and preparation methods, to broaden spectral response, reduce photogenerated electron-space Acupoint pair recombination, reducing the effect of light reflection intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

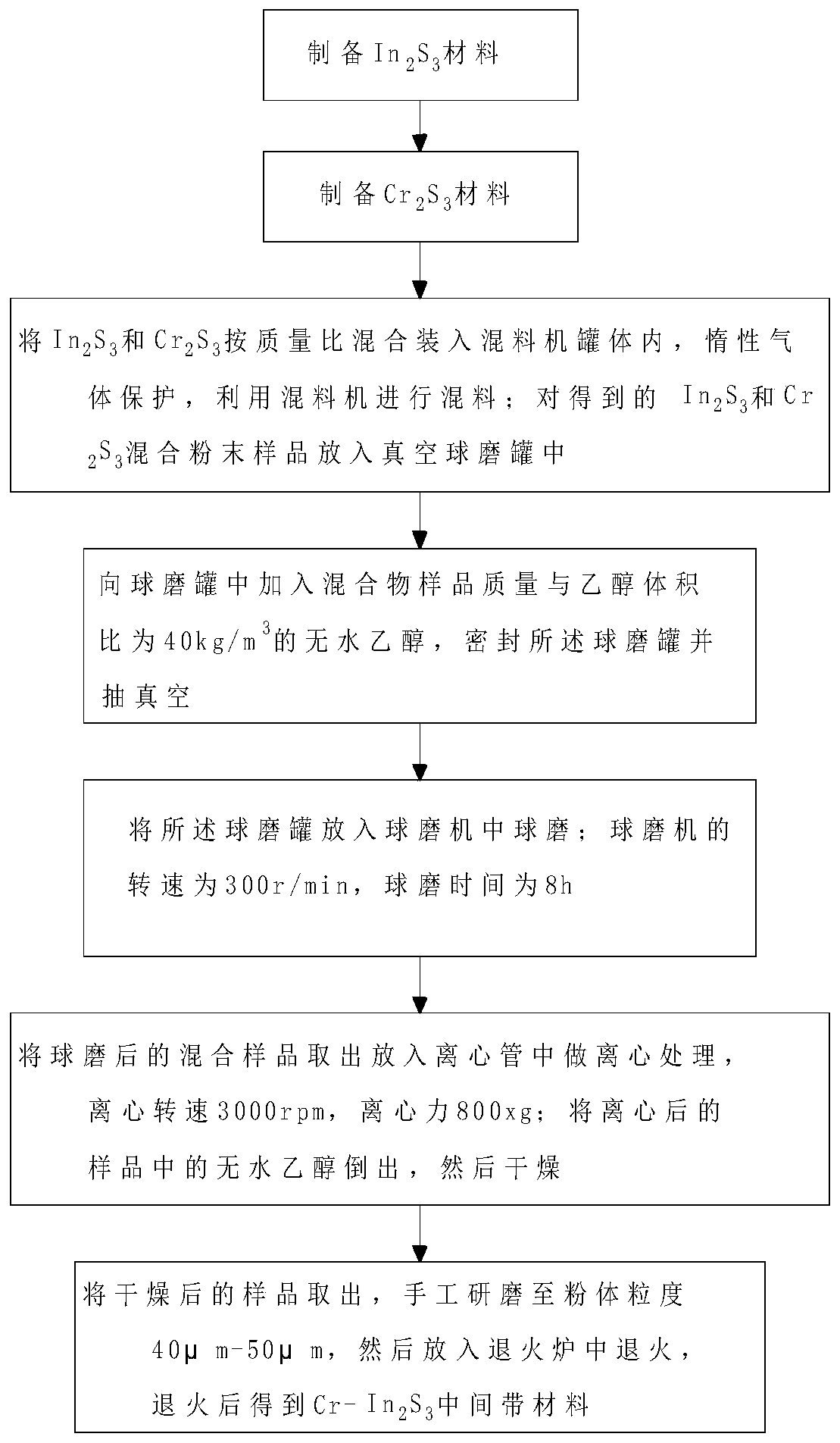

[0052] For the preparation process, please refer to figure 1 , a Cr-doped In of this embodiment 2 S 3 The preparation method of intermediate zone material, its method step is as follows:

[0053] Step 1: Preparation of In 2 S 3 Material, 99.99% pure; weighs 10 grams. Weighing adopts the electronic balance scale of model BSA124S-CW produced by Sai Duo Kesi Scientific Instrument Co., Ltd.

[0054] Step 2: Preparation of Cr 2 S 3 Material, 99.99% pure; weighs 0.3234 grams. Weighing adopts the electronic balance scale of model BSA124S-CW produced by Sai Duo Kesi Scientific Instrument Co., Ltd.

[0055] Step 3: Put In 2 S 3 and Cr 2 S 3 The mixed material is put into the tank body of the mixer, the rotating speed of the mixer is 20r / min, the mixing time is 10h, the inert gas argon protection is passed into, and then the mixer is used for mixing; the mixed powder is obtained; In 2 S 3 and Cr 2 S 3 The mixed powder samples were put into a vacuum ball mill jar.

[00...

Embodiment 2

[0061] For the preparation process, please refer to figure 1 , a Cr-doped In of this embodiment 2 S 3 The preparation method of intermediate zone material, its method step is as follows:

[0062] Step 1: Preparation of In 2 S 3 Material, 99.99% pure; weighs 100 grams. Weighing adopts the electronic balance scale of model BSA124S-CW produced by Sai Duo Kesi Scientific Instrument Co., Ltd.

[0063] Step 2: Preparation of Cr 2 S 3 Material, 99.99% pure; weighs 3.33 grams. Weighing adopts the electronic balance scale of model BSA124S-CW produced by Sai Duo Kesi Scientific Instrument Co., Ltd.

[0064] Step 3: Put In 2 S 3 and Cr 2 S 3 The mixed material is put into the tank body of the mixer, the rotating speed of the mixer is 50r / min, and the mixing time is 20h, and the inert gas nitrogen protection is passed into, and then the mixer is used for mixing; the mixed powder is obtained; the obtained In 2 S 3 and Cr 2 S 3 The mixed powder samples were put into a vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com