Arc boosting and current increasing method for overlap joint of annular elastic belts and based on cooperative adjustment of multiple parameters

A multi-parameter, elastic belt technology, used in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low projectile strength, inconsistent height of lap joints, and difficult belt welding, so as to improve the power of the shell and solve the Difficulty in welding and the effect of increasing the amount of filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

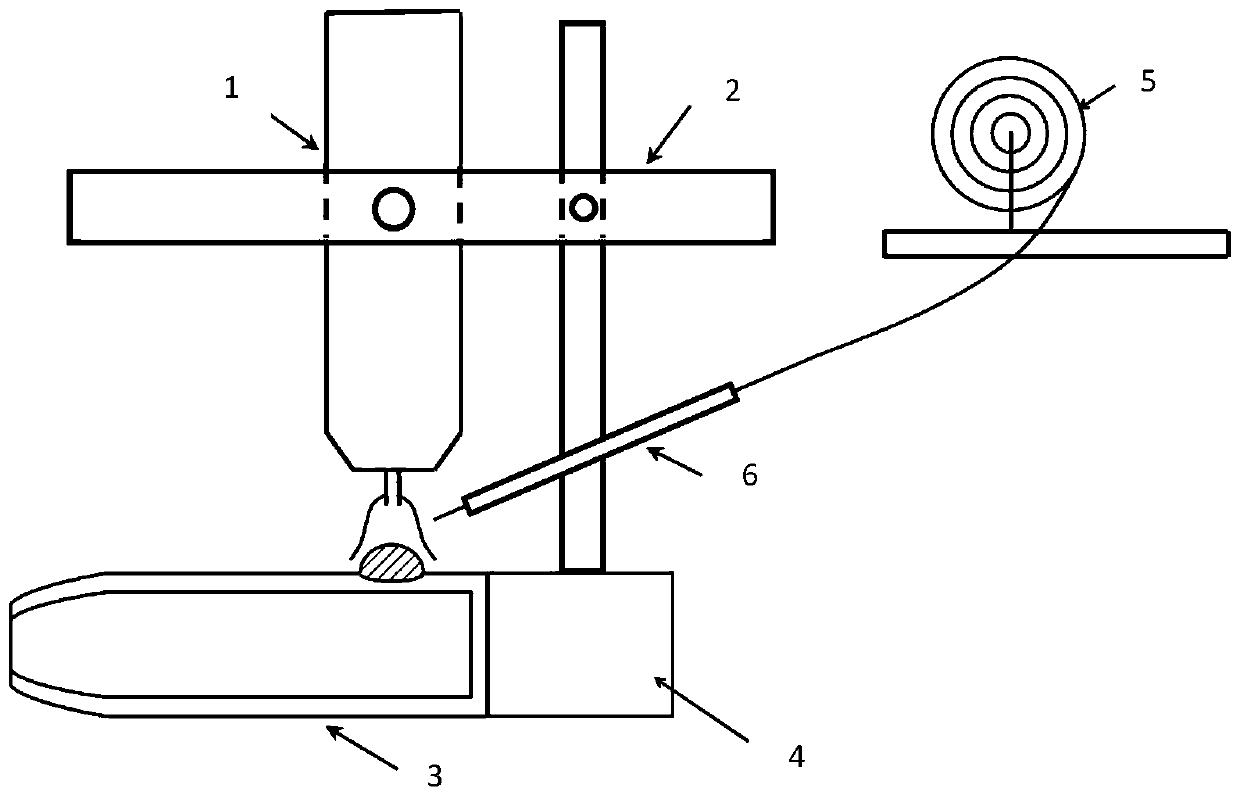

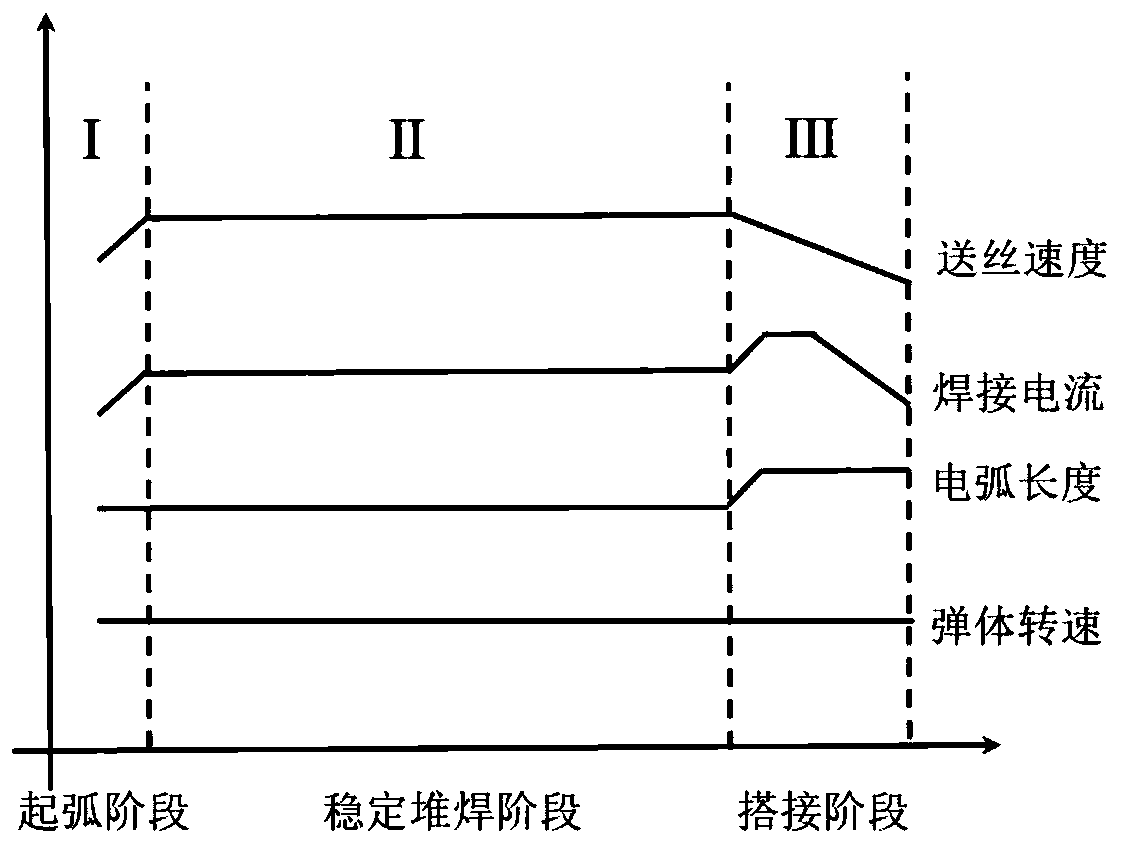

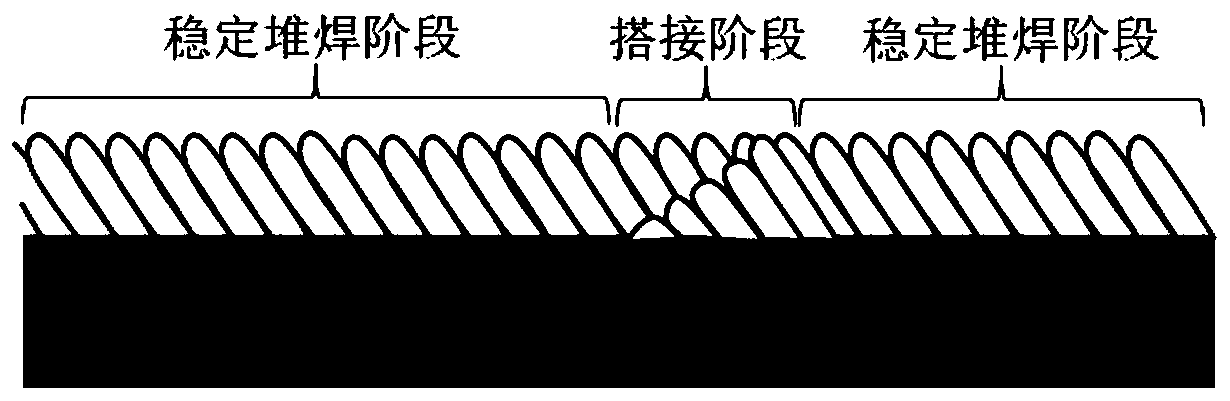

[0016] Specific implementation mode one: combine Figure 1~3 Description of this embodiment, a multi-parameter cooperative adjustment arc raising and current raising method for ring elastic belt lapping, which includes three stages, followed by arc starting stage, stable surfacing stage and lapping stage, and the speed range of the projectile body is 0.1- 20r / min and keep the speed of the projectile constant during the welding process.

[0017] The first stage is the arc starting stage. In this stage, the welding current is linearly increased to 50-200A, the wire feeding speed is 0.5-20m / min, and the arc length is 1mm-5mm.

[0018] The second stage is the stable surfacing stage. In this stage, the welding current is stabilized at 50-200A, the wire-feeding speed is 0.5-20m / min, the arc length is 1mm-5mm, and the welding current, wire-feeding speed and arc length are kept stable. .

[0019] The third stage is the lap joint stage. In this stage, the welding current rises to 120...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 1~3 To illustrate this embodiment, when the surfacing welding material is copper, that is, during the lap forming process of the surfacing welding copper elastic band, the rotational speed of the projectile during the welding process is 1.5r / min and remains constant, and the flow rate of argon gas is 10L / min and remains constant. In the welding process, the welding current in the arc starting stage increases linearly to 160A, the wire feeding speed increases linearly to 1.4m / min, and the arc length is 3mm; the welding current in the stable surfacing stage is stable at 160A, and the wire feeding speed is 1.4m / min, the arc length is 3mm, and remains stable; the wire feeding speed is gradually reduced from 1.4m / min to 0m / min during the lapping stage, and the arc length is elongated to 4mm, and the pre-crystallization surfacing layer is controlled by changing the current characteristics , the temperature rises to make it...

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 1~3 To illustrate this embodiment, when the surfacing welding material is soft iron, that is, during the lap forming process of the surfacing welding soft iron elastic belt, the rotational speed of the projectile during the welding process is 1r / min and remains unchanged, and the flow rate of argon gas is 12L / min and Keeping the same, in the welding process, the welding current in the arc starting stage increases linearly to 165A, the wire feeding speed increases linearly to 1.3m / min, and the arc length is 2.8mm; in the stable surfacing stage, the welding current is stable at 160A, and the wire feeding speed is linearly increased to 1.3m / min. The wire speed is 1.3m / min, the arc length is 2.8mm, and remains stable; the wire feeding speed is gradually reduced from 1.3m / min to 0m / min during the lapping stage, and the arc length is elongated to 4.5mm. characteristics to control the first crystallization of the surfacin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap