A flue gas acid production system that recovers the low-level heat of the second suction process

A technology for making acid and flue gas from flue gas, which is applied in the direction of inorganic chemistry, chemical instruments and methods, sulfur compounds, etc., can solve the problems of unusable and waste of heat, and achieve the effect of reasonable setting, economic benefits and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

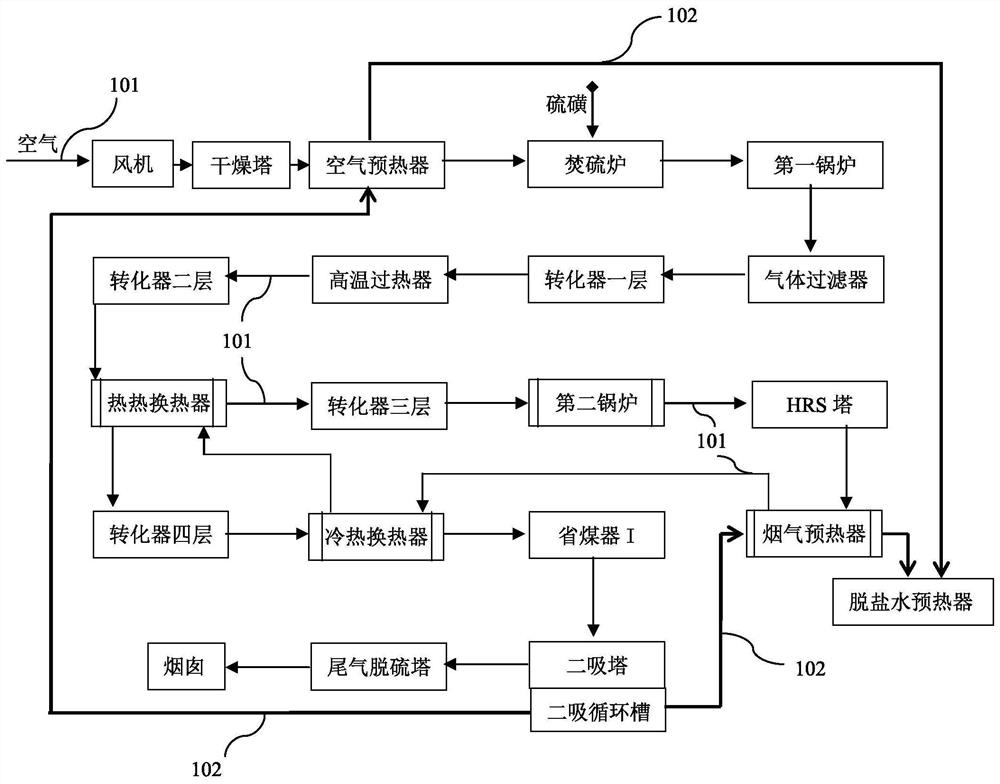

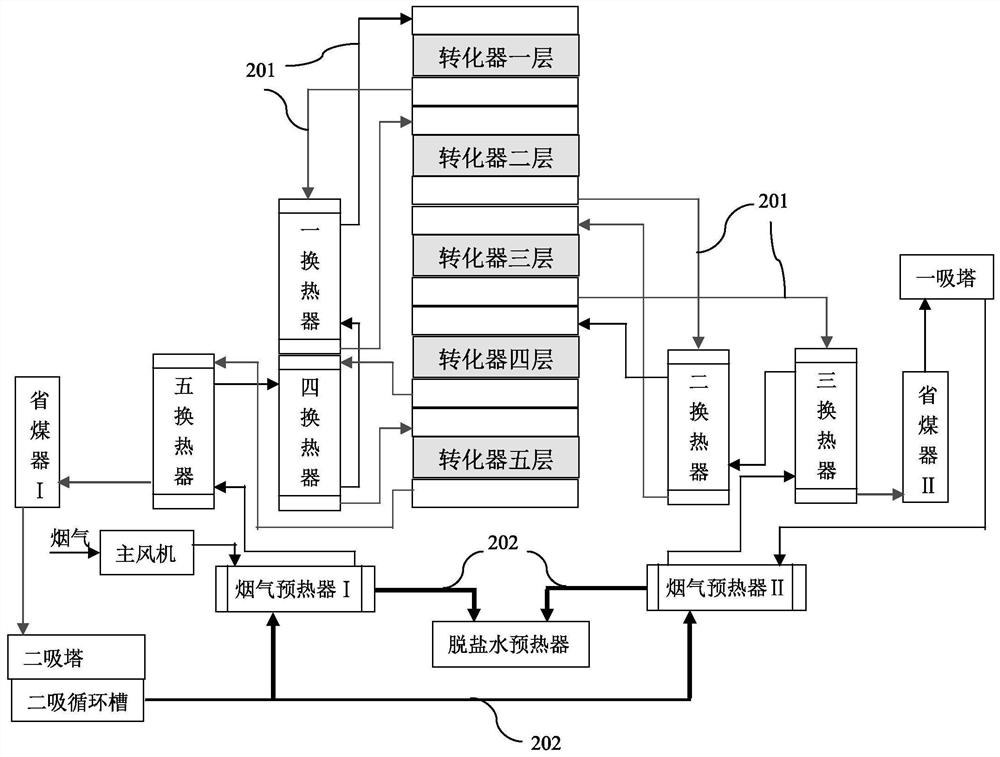

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment, but does not limit the present invention thereby. The operation methods and devices involved in the following examples are conventional methods and devices unless otherwise specified.

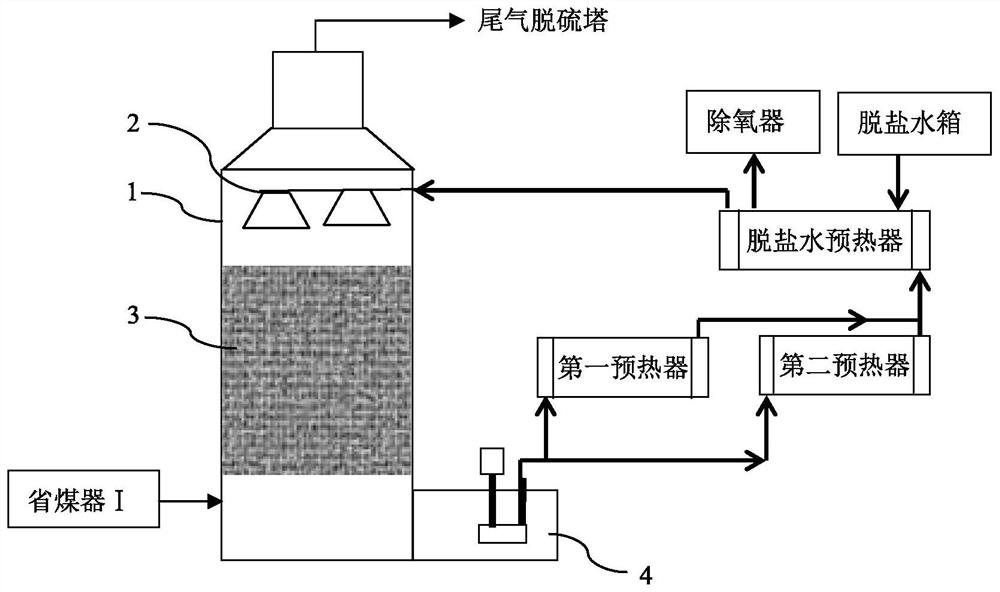

[0025] The invention provides a second absorption tower capable of realizing low-level heat recovery. The second absorption tower is used for secondary absorption of sulfur trioxide in the sulfuric acid preparation process. The second absorption tower includes a tower body and an acid separation tower arranged on the upper part of the tower device, the packing arranged under the acid separator and the acid circulation tank arranged at the bottom of the tower body, the spray density of the acid separator of the second suction tower is set at 2.0-3.5m 3 / m 2 · h; the packing of the second suction tower is set as a ceramic packing with a diameter of 20-50 mm.

[0026] The spray density of 98% sulfuric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com