Bismuth ferrite and barium titanate-based ceramic with high energy storage density and high power density and preparation method thereof

A bismuth ferrite barium titanate, high power density technology, applied in the field of ceramic dielectric materials for pulse power capacitors, can solve the problems of inability to replace lead-based ceramic materials, low energy storage density and energy storage efficiency, etc. Recalcitrant field and remanent polarization, improving energy storage performance, effect of high saturation polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

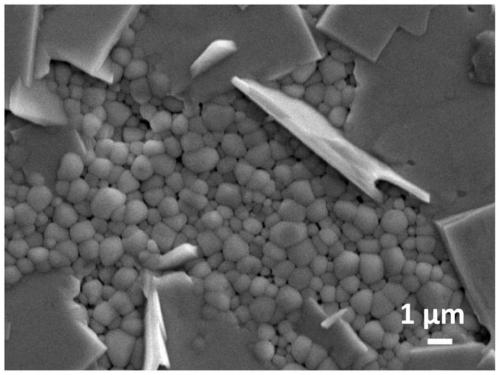

[0038] The preparation conforms to the chemical composition (1-x) (0.67BiFeO 3 -0.33BaTiO 3 )-xBaBi 2 Nb 2 o 9 , the lead-free energy storage ceramics of x=0.02, comprising the following steps:

[0039](1) Ingredients: Bi 2 o 3 Powder, Fe 2 o 3 Powder, BaCO 3 Powder, TiO 2 Powder and Nb 2 o 5 Powder is used as raw material, according to the general formula 0.98(0.67BiFeO 3 -0.33BaTiO 3 )-0.02BaBi 2 Nb 2 o 9 The stoichiometry of Bi, Ba, Fe, Ti and Nb in the mixture is batched;

[0040] (2) One-time ball milling: add absolute ethanol equal to the mixture to the above mixture, and continue ball milling for 12 hours, so that the powder is mixed evenly to form a slurry, which can further improve the comprehensive performance of bismuth ferrite barium titanate ceramic materials performance;

[0041] (3) drying: the above slurry is placed in a constant temperature oven to bake, remove absolute ethanol, and grind in a mortar to obtain powder;

[0042] (4) Tablet pre...

Embodiment 2

[0049] The preparation conforms to the chemical composition (1-x) (0.67BiFeO 3 -0.33BaTiO 3 )-xBaBi 2 Nb 2 o 9 , the lead-free energy storage ceramics of x=0.04, comprising the following steps:

[0050] (1) Ingredients: Bi 2 o 3 Powder, Fe 2 o 3 Powder, BaCO 3 Powder, TiO 2 Powder and Nb 2 o 5 Powder is used as raw material, according to the general formula 0.96(0.67BiFeO 3 -0.33BaTiO 3 )-0.04BaBi 2 Nb 2 o 9 The stoichiometry of Bi, Ba, Fe, Ti and Nb in the mixture is batched;

[0051] (2) One-time ball milling: add absolute ethanol equal to the mixture to the above mixture, and continue ball milling for 12 hours, so that the powder is mixed evenly to form a slurry, which can further improve the comprehensive performance of bismuth ferrite barium titanate ceramic materials performance;

[0052] (3) drying: the above slurry is placed in a constant temperature oven to bake, remove absolute ethanol, and grind in a mortar to obtain powder;

[0053] (4) Tablet pr...

Embodiment 3

[0060] The preparation conforms to the chemical composition (1-x) (0.67BiFeO 3 -0.33BaTiO 3 )-xBaBi 2 Nb 2 o 9 , the lead-free energy storage ceramics of x=0.06, comprising the following steps:

[0061] (1) Ingredients: Bi 2 o 3 Powder, Fe 2 o 3 Powder, BaCO 3 Powder, TiO 2 Powder and Nb 2 o 5 Powder is used as raw material, according to the general formula 0.94(0.67BiFeO 3 -0.33BaTiO 3 )-0.06BaBi 2 Nb 2 o 9 The stoichiometry of Bi, Ba, Fe, Ti and Nb in the mixture is batched;

[0062] (2) One-time ball milling: add absolute ethanol equal to the mixture to the above mixture, and continue ball milling for 12 hours, so that the powder is mixed evenly to form a slurry, which can further improve the comprehensive performance of bismuth ferrite barium titanate ceramic materials performance;

[0063] (3) drying: the above slurry is placed in a constant temperature oven to bake, remove absolute ethanol, and grind in a mortar to obtain powder;

[0064] (4) Tablet pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com