Thickening agent for acid fracturing and preparation method thereof

A technology of acid fracturing and thickening agent, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that cannot fully meet the needs of deep well reservoir reconstruction, and achieve the effect of mild reaction conditions and meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of thickener of the present invention is:

[0030] (1) Dissolve 2-acrylamide-2-methylpropanesulfonic acid in pure water, add NaOH, and adjust the pH value of the solution to 7; then acrylamide, N-vinylpyrrolidone, acetic acid and diethylenetriamine After dissolving in pure water, it can be miscible with 2-acrylamide-2-methylpropanesulfonic acid solution, add pure water and stir evenly to obtain standby solution Ⅰ; raw materials acrylamide, 2-acrylamide-2-methylpropanesulfonic acid , The weight ratio of N-vinylpyrrolidone, acetic acid and diethylenetriamine is 7:1:0.5:0.2:0.2;

[0031] (2) Take the spare solution I and inject it into the reaction container, under the protection of nitrogen, raise the temperature to 70°C, take ammonium persulfate and sodium bisulfite, add them to the spare solution I, continue to fill with nitrogen, airtight, and stir at 70°C 4.5h, the colloid was obtained; the weight ratio of ammonium persulfate to sodium bisulfit...

Embodiment 2

[0036] The preparation method of thickener of the present invention is:

[0037] (1) Dissolve 2-acrylamide-2-methylpropanesulfonic acid in pure water, add NaOH, and adjust the pH value of the solution to 7; then acrylamide, N-vinylpyrrolidone, acetic acid and diethylenetriamine After dissolving in pure water, it can be miscible with 2-acrylamide-2-methylpropanesulfonic acid solution, add pure water and stir evenly to obtain standby solution Ⅰ; raw materials acrylamide, 2-acrylamide-2-methylpropanesulfonic acid , The weight ratio of N-vinylpyrrolidone, acetic acid and diethylenetriamine is 7.5:3:1:0.4:0.4;

[0038] (2) Take the spare solution I and inject it into the reaction container, under the protection of nitrogen, heat up to 80°C, take ammonium persulfate and sodium bisulfite, add them to the spare solution I, and continue to fill with nitrogen, airtight, and stir at 80°C 3.5h, the colloid was obtained; the weight ratio of ammonium persulfate to sodium bisulfite was 1:1;...

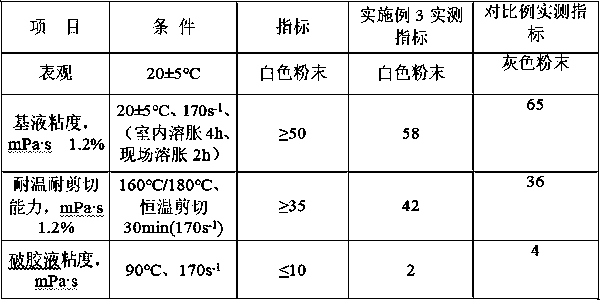

Embodiment 3

[0043] The preparation method of thickener of the present invention is:

[0044] (1) Dissolve 2-acrylamide-2-methylpropanesulfonic acid in pure water, add NaOH, and adjust the pH value of the solution to 7; then acrylamide, N-vinylpyrrolidone, acetic acid and diethylenetriamine After dissolving in pure water, it can be miscible with 2-acrylamide-2-methylpropanesulfonic acid solution, add pure water and stir evenly to obtain standby solution Ⅰ; raw materials acrylamide, 2-acrylamide-2-methylpropanesulfonic acid , The weight ratio of N-vinylpyrrolidone, acetic acid and diethylenetriamine is 7.3:2:0.7:0.3:0.3;

[0045] (2) Take the spare solution I and inject it into the reaction container, under the protection of nitrogen, heat up to 75°C, take ammonium persulfate and sodium bisulfite, add them to the spare solution I, and continue to fill with nitrogen, airtight, and stir at 75°C 4h, the colloid was obtained; the weight ratio of ammonium persulfate to sodium bisulfite was 1:1;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com