Halogen-free flame-retardant thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of polyurethane elastomers, can solve the problems of incompatibility of flame retardant properties, mechanical properties and processing properties, and achieve the effects of maintaining good mechanical properties, delaying slippage and improving melt strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The invention relates to a preparation method of a halogen-free flame-retardant thermoplastic polyurethane elastomer. The thermoplastic polyurethane polymer, long-chain alkylbenzimidazole and inorganic filler are used as main raw materials, mixed and extruded through a twin-screw extruder. The raw materials may also include antioxidants and lubricants; wherein, the extrusion temperature of the twin-screw extruder is 150-220° C., and the screw speed is 150-300 r / min.

[0067] Raw material preparation:

[0068] Thermoplastic polyurethane polymer (TPU): ES85 (polyester TPU with Shore hardness of 85A), 1185 (polyether TPU with Shore hardness of 85A), all purchased from BASF, Germany;

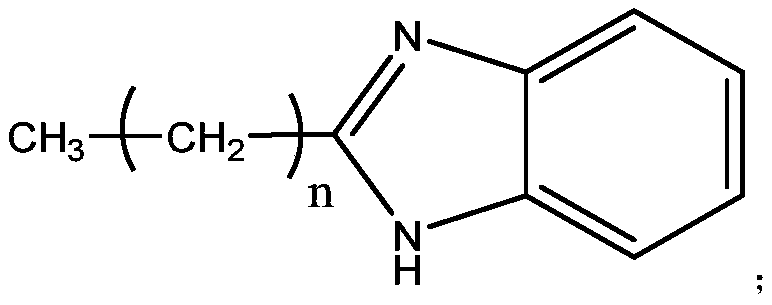

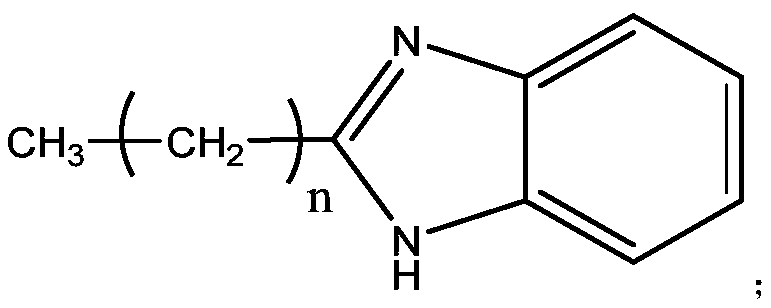

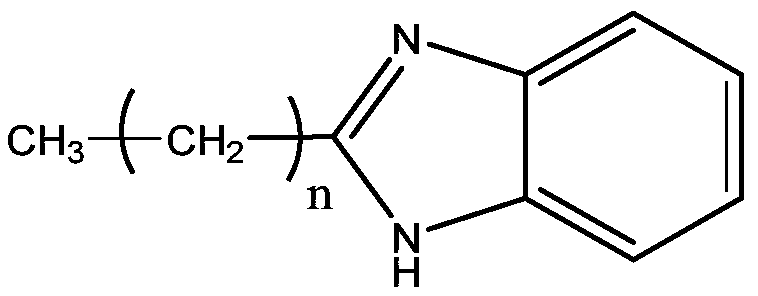

[0069] Long-chain alkylbenzimidazole: 2-tridecylbenzimidazole, prepared according to the method in the literature [Zhang Jingming et al., Guizhou Chemical Industry, 2009, 34 (5): 11]; the structural formula is:

[0070]

[0071] where n=12;

[0072] Substance B: Resorcinol bis(diphenyl) ...

Embodiment 1

[0088] A preparation method of a halogen-free flame-retardant thermoplastic polyurethane elastomer is: in parts by weight, 100 parts of ES85, 15 parts of alkylbenzimidazole (i.e. 2-tridecylbenzimidazole), 5 parts of layered Silicate filler A, 0.2 part of antioxidant 1010, 0.4 part of antioxidant 626 and 0.2 part of lubricant WAX C are mixed evenly and then added to a heated twin-screw extruder (model CTE50, purchased from Coperion (Nanjing) Machinery Co., Ltd.); the temperature of each section of the screw extruder is 180°C, 220°C, 220°C, 220°C, 220°C, 210°C, 210°C, 200°C, 180°C, the head temperature is 180°C, and the screw speed setting 200r / min;

[0089] The performance test of the prepared halogen-free flame-retardant thermoplastic polyurethane elastomer is shown in Table 1.

Embodiment 2

[0105] A preparation method of a halogen-free flame-retardant thermoplastic polyurethane elastomer is: in parts by weight, each component is mixed according to the addition amount in Table 2, and then added to a heated twin-screw extruder (same as Example 1) The temperature of each section of the screw extruder is 180°C, 200°C, 200°C, 200°C, 200°C, 195°C, 195°C, 185°C, 185°C, the head temperature is 185°C, and the screw speed is set to 160r / min.

[0106] The performance test of the prepared halogen-free flame-retardant thermoplastic polyurethane elastomer is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com