Refined sugar decolorization treatment device and decolorization, backwashing, regeneration and cleaning process

A processing device and anti-regeneration technology, which is applied in sucrose production, sugar production, ion exchange regeneration, etc., can solve the problems of increasing regeneration cost, shortening resin life, and high resin price, so as to reduce difficulty, improve capacity and efficiency, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

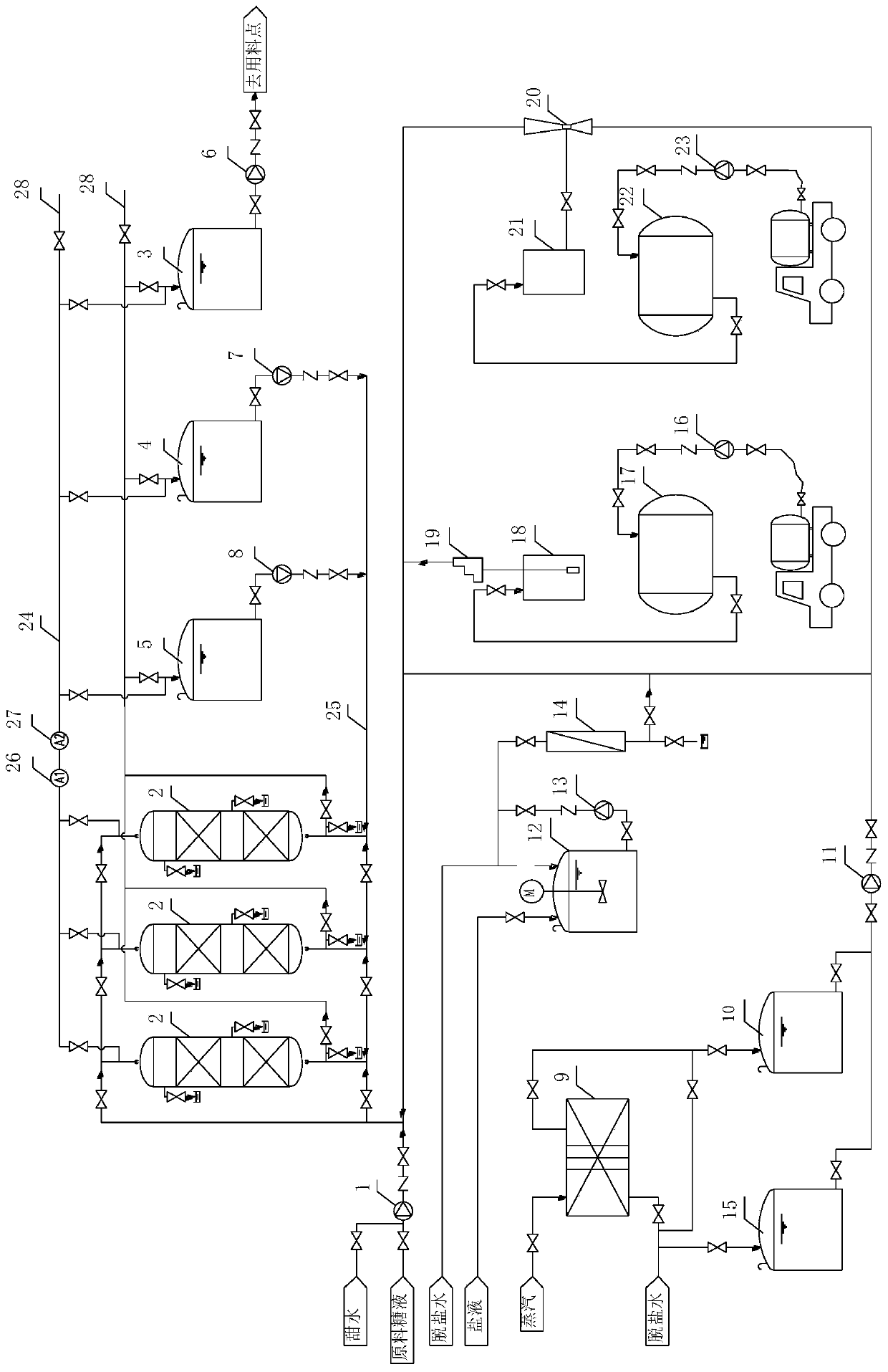

[0061] This embodiment provides a refined sugar decolorization treatment device, including an operating system, a regeneration system and an anti-regeneration system.

[0062] Such as figure 1 As shown, the operating system includes a syrup pump, a decolorized sugar solution pump 6, an ion exchange bed group, a dilute sugar solution tank 5, a concentrated sugar solution tank 4 and a decolorized sugar solution tank 3, wherein the ion exchange bed group is provided with three ion exchange Bed 2, the inner cavity of each ion exchange bed 2 is divided into an upper chamber and a lower chamber, the upper chamber is filled with acrylic resin and the lower chamber is filled with styrene resin. The three ion exchange beds 2 are sequentially connected to the decolorization program. Compared with a single ion exchange bed 2, the three ion exchange beds 2 can improve the decolorization capacity. The upper port and the lower port of each ion exchange bed 2 are provided with inlet and out...

Embodiment 2

[0069] This embodiment provides a decolorization treatment process, based on a refined sugar decolorization treatment device in Example 1, comprising the following steps:

[0070] S1: Add sugar,

[0071] S11: Pump sweet water from the lower port of each ion exchange bed through a syrup pump to soak the resin inside the ion exchange bed;

[0072] S12: The dilute sugar solution pump draws the dilute sugar solution from the dilute sugar solution tank and pumps it in from the lower port of each ion exchange bed. The upper port of each ion exchange bed is returned to the dilute sugar solution tank;

[0073] S13: The concentrated sugar solution pump draws the concentrated sugar solution from the concentrated sugar solution tank and pumps it in from the lower port of each ion exchange bed. The upper port of each ion exchange bed is returned to the concentrated sugar solution tank, and the sugar feeding is completed;

[0074] S2: decolorization run,

[0075] S21: In S13, when the ...

Embodiment 3

[0085] This embodiment provides a backwash treatment process, based on the refined sugar decolorization treatment device of Example 1, the resin in the ion exchange bed is blocked by suspended matter and affects the passing of the sugar solution, then the following steps are performed:

[0086] S1: The external salt solution pipeline leads to the desalted salt water tank, and the desalted water is pumped in from the lower port of each ion exchange bed through the salt solution pump and bag filter. The flow rate is 1~2BV / h. The input time is 1 hour, and the eluate is discharged from the waste liquid pipe;

[0087] S2: The external desalinated water pipeline pumps desalted water at 70-80°C into the desalted water tank and the heat preservation water tank, and then pumps it in from the upper port of each ion exchange bed through the regeneration pump. After 1 hour, the eluate is discharged from the waste pipe, and the backwashing is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com