LED light-emitting structure and light-emitting spike with same

A technology of light emission and road studs, which is applied to the semiconductor devices of light-emitting elements, roads, light sources, etc., can solve the problems of non-compression and impact resistance, poor structural strength, cumbersome manufacturing and installation, etc., and increase the compression and impact resistance performance, improve the shell structure, increase the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

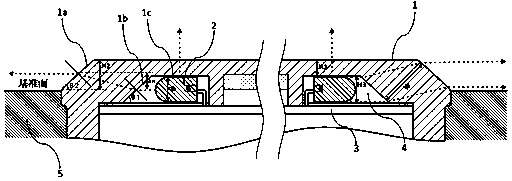

[0101] A solar luminous reflective raised road stud, comprising one transparent shell (110), one LED straw hat lamp (120), one partition (130), one air layer (140), and one accommodating cavity (150) , Bottom case one (160), retro reflector one (170), photovoltaic module one (180), control circuit one (190), energy storage element one (1100), such as Figure 5 —13 shown.

[0102] Transparent shell one (110):

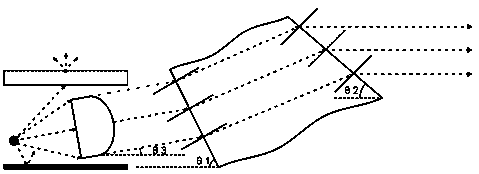

[0103] Transparent shell one (110) is an injection-molded part similar to a rectangular parallelepiped with a downwardly opened cavity formed by a transparent PC through an injection process. The four corners of the top are recessed downward to form two sets of positive and back slopes with a height of 6mm and a thickness of 10mm. The outer slope (110a) and the inner slope (110b) of the slope are parallel to each other and are parallel to the top surface. It has an included angle of 45°. Between the inner slopes (110b) of each group, there is an arched top (similar to an inv...

Embodiment 2

[0123] A solar luminous reflective raised road stud, comprising two transparent shells (210), two LED straw hat beads (220), two separators (230), two air layers (240), two retroreflectors (270), Photovoltaic module two (280), control circuit two (290), energy storage element two (2100), such as Figure 14 —17 shown.

[0124] Transparent shell two (210):

[0125] The second transparent shell (210) is an injection molded part of transparent PC with a downwardly opened cavity. Its shape is similar to a table body. The front and rear sides are respectively provided with opposite slopes that intersect the bottom surface at an angle of 30° and each has a convex groove. The left and right sides protrude outward in an arc shape and are respectively taped There is a mounting hole, the four corners of the top are recessed downward to form two sets of opposite slopes with a height of 6mm and a thickness of 9mm in front and back directions. The outer slopes of the slopes are two (210a) and t...

Embodiment 3

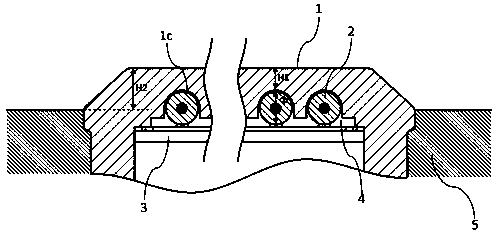

[0139] A buried solar luminous road stud, comprising three transparent shells (310), three LED straw hat beads (320), three partitions (330), three air layers (340), three top covers (361), and bottom Shell three (362), photovoltaic module three (380), control circuit three (390), energy storage element three (3100), external waterproof wire three, such as Figure 18 —21 shown.

[0140] Transparent shell three (310):

[0141] Transparent shell three (310) is a fully transparent PC shell, and the shape is similar to an inverted transparent ashtray. Its lower part is a petal-shaped column, and its top is provided with a cross-shaped upward convex corresponding to the cross-shaped window on the top cover three (361), and the four relatively sinking concave parts are provided with two sets of forward and backward , A relative inclined plane with a height of 6.5mm and a thickness of 10mm, the outer inclined plane 3 (310a) and the inner inclined plane 3 (310b) of the inclined plane are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com