Preparation method of edible fungus rice

A technology of edible fungus rice and edible fungus, which is applied in the fields of application, food drying, food science, etc., can solve problems such as difficulty in obtaining steamed products, not conforming to the fast pace of life, and affecting the sense of experience, etc., to achieve fresh taste and natural color , the effect of prolonging the preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

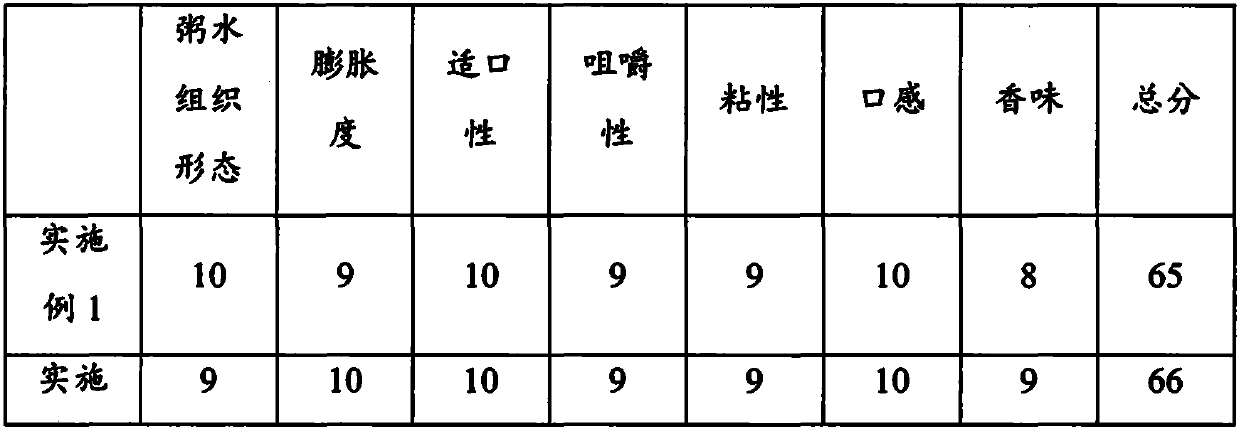

Embodiment 1

[0040] (1) Preparation of pretreated matsutake:

[0041] (11) Remove impurities from fresh matsutake, rinse with water for 5 minutes, and drain;

[0042] (12) cut into 2mm thin slices and carry out cryopreservation afterwards;

[0043] (13) Afterwards, freeze-drying treatment is carried out, and the parameters of each stage are set as follows: first stage temperature -45°C, time 3h; second stage temperature -60°C, time 5h; third stage temperature -20°C, time 4h; fourth stage Stage temperature 0°C, time 4h; fifth stage temperature 10°C, time 2h; sixth stage temperature 25°C, time 5h, to obtain freeze-dried matsutake;

[0044] (14) The freeze-dried matsutake is subjected to wall-breaking treatment by ultrafine pulverization technology, and the particle size after treatment is less than 45 μm, and the pretreated matsutake is obtained.

[0045] (2) Preparation of pretreated rice:

[0046] (21) crushing: the rice is crushed to a particle size of 2mm;

[0047] (22) Polishing: ad...

Embodiment 2

[0056] (1) Preparation of pretreated matsutake:

[0057] (11) Remove impurities from fresh matsutake, rinse with water for 15 minutes, and drain;

[0058] (12) cut into 8mm thin slices and carry out cryopreservation afterwards;

[0059] (13) Afterwards, freeze-drying treatment is carried out, and the parameters of each stage are set as follows: first stage temperature -45°C, time 3h; second stage temperature -60°C, time 5h; third stage temperature -20°C, time 4h; fourth stage Stage temperature 0°C, time 4h; fifth stage temperature 10°C, time 2h; sixth stage temperature 25°C, time 5h, to obtain freeze-dried matsutake;

[0060] (14) The freeze-dried matsutake is subjected to wall-breaking treatment by ultrafine pulverization technology, and the particle size after treatment is less than 45 μm, and the pretreated matsutake is obtained.

[0061] (2) Preparation of pretreated rice:

[0062] (21) crushing: the rice is crushed to a particle size of 3 mm;

[0063] (22) Polishing: ...

Embodiment 3

[0072] (1) Preparation of pretreated matsutake:

[0073] (11) Remove impurities from fresh matsutake, rinse with water for 10 minutes, and drain;

[0074] (12) cut into 5mm thin slices and carry out cryopreservation afterwards;

[0075] (13) Afterwards, freeze-drying treatment is carried out, and the parameters of each stage are set as follows: first stage temperature -45°C, time 3h; second stage temperature -60°C, time 5h; third stage temperature -20°C, time 4h; fourth stage Stage temperature 0°C, time 4h; fifth stage temperature 10°C, time 2h; sixth stage temperature 25°C, time 5h, to obtain freeze-dried matsutake;

[0076] (14) The freeze-dried matsutake is subjected to wall-breaking treatment by ultrafine pulverization technology, and the particle size after treatment is less than 45 μm, and the pretreated matsutake is obtained.

[0077] (2) Preparation of pretreated rice:

[0078] (21) crushing: the rice is crushed to a particle size of 2 mm;

[0079] (22) Polishing: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com