System and method for multistage desulfurization rich liquid cavitation desorption of sulfur dioxide

A technology for desulfurization rich liquid and sulfur dioxide, applied in chemical instruments and methods, sulfur compounds, separation methods, etc., can solve the problems of high investment, large-scale heat transmission equipment and water vapor condensation equipment, high heat consumption, etc., to reduce condensation load , The effect of reducing the steam condensation load and reducing the amount of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

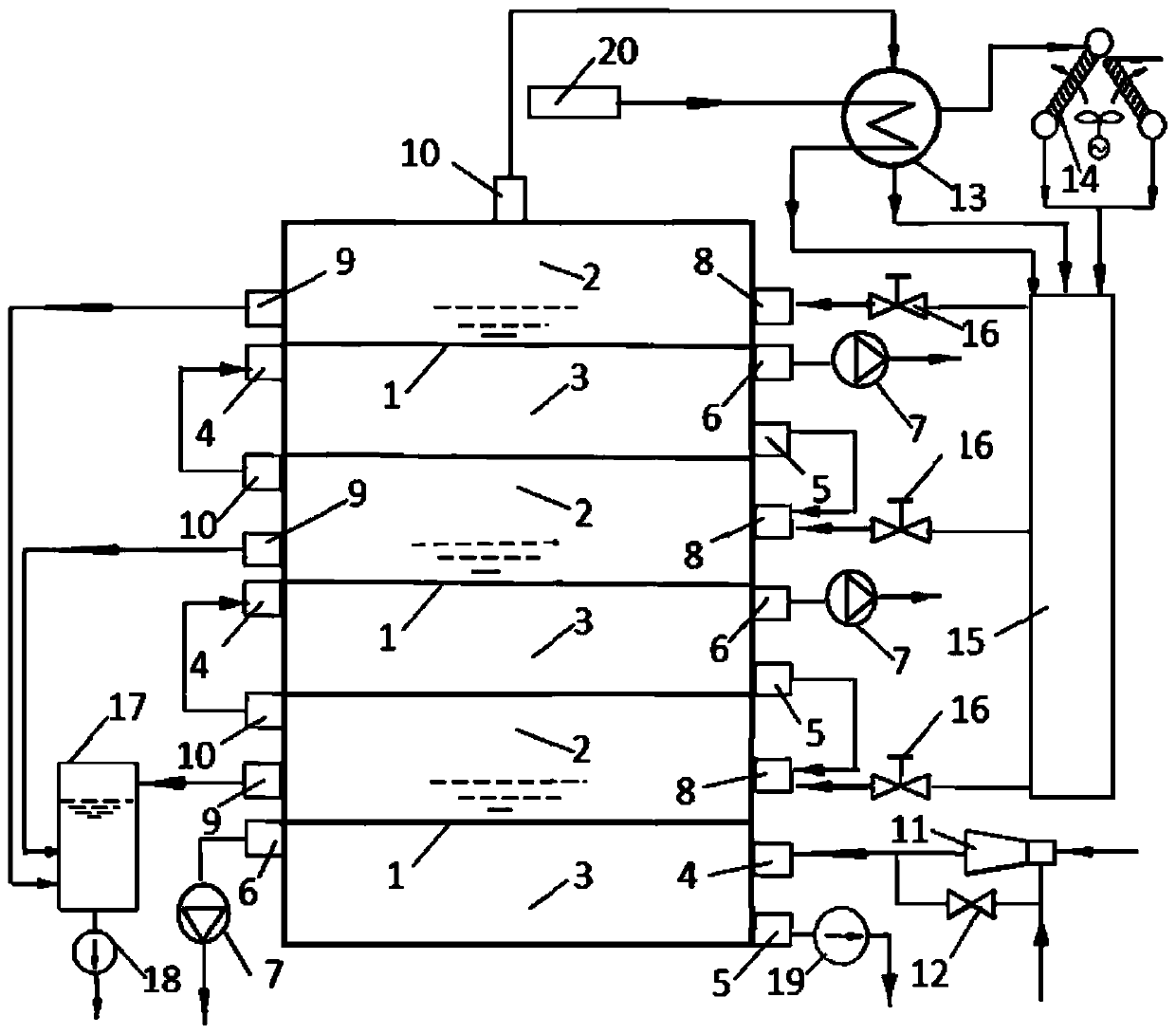

[0048] Taking the system of three-stage desulfurization rich liquid cavitation desorption sulfur dioxide as an example, set the cavitation desorption temperature of the basic aluminum sulfate desulfurization rich liquid in the cavitation desorption chamber 2 of the final cavitation desorption unit to be 55°C, and the cavitation desorption temperature of the two adjacent cavitation desorption units The inter-stage temperature difference of desulfurization rich liquid cavitation desorption temperature of the desulfurization desorption unit is set at 5°C, and the cavitation temperature of desulfurization rich liquid in the same stage is the same as that of the steam or steam, SO 2 The temperature difference of the mixed gas is set at 5°C; the exhaust steam from the steam turbine operating at a back pressure of 12.34kPa is used as the supply for cavitation desorption of SO 2 The heat source of the heat, the exhaust steam of the steam turbine corresponds to a steam temperature of ab...

Embodiment 2

[0064] Taking the system of three-stage desulfurization rich liquid cavitation desorption sulfur dioxide as an example, set the cavitation desorption temperature of the basic aluminum sulfate desulfurization rich liquid in the cavitation desorption chamber 2 of the final cavitation desorption unit to be 55°C, and the cavitation desorption temperature of the two adjacent cavitation desorption units The inter-stage temperature difference of desulfurization-rich liquid cavitation desorption temperature of the desulfurization desorption unit is set at 5°C, and the cavitation temperature of the desulfurization-rich liquid cavitation temperature of the cavitation desorption unit of the same stage is the same as that of the steam or steam in the steam heating chamber 3, SO 2 The temperature difference of the mixed gas is set at 5°C; the exhaust steam from the steam turbine operating at a back pressure of 31.16kPa is used as the supply for cavitation desorption of SO 2 As the heat sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com