Fireproof coating raw material preparation device

A technology for preparing equipment and fireproof coatings, which is applied in zirconia, dispersed particle filtration, gas treatment, etc., can solve the problems of waste of finished zirconia and reduction of zirconia output, etc., to reduce waste, reduce production costs, and improve production output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

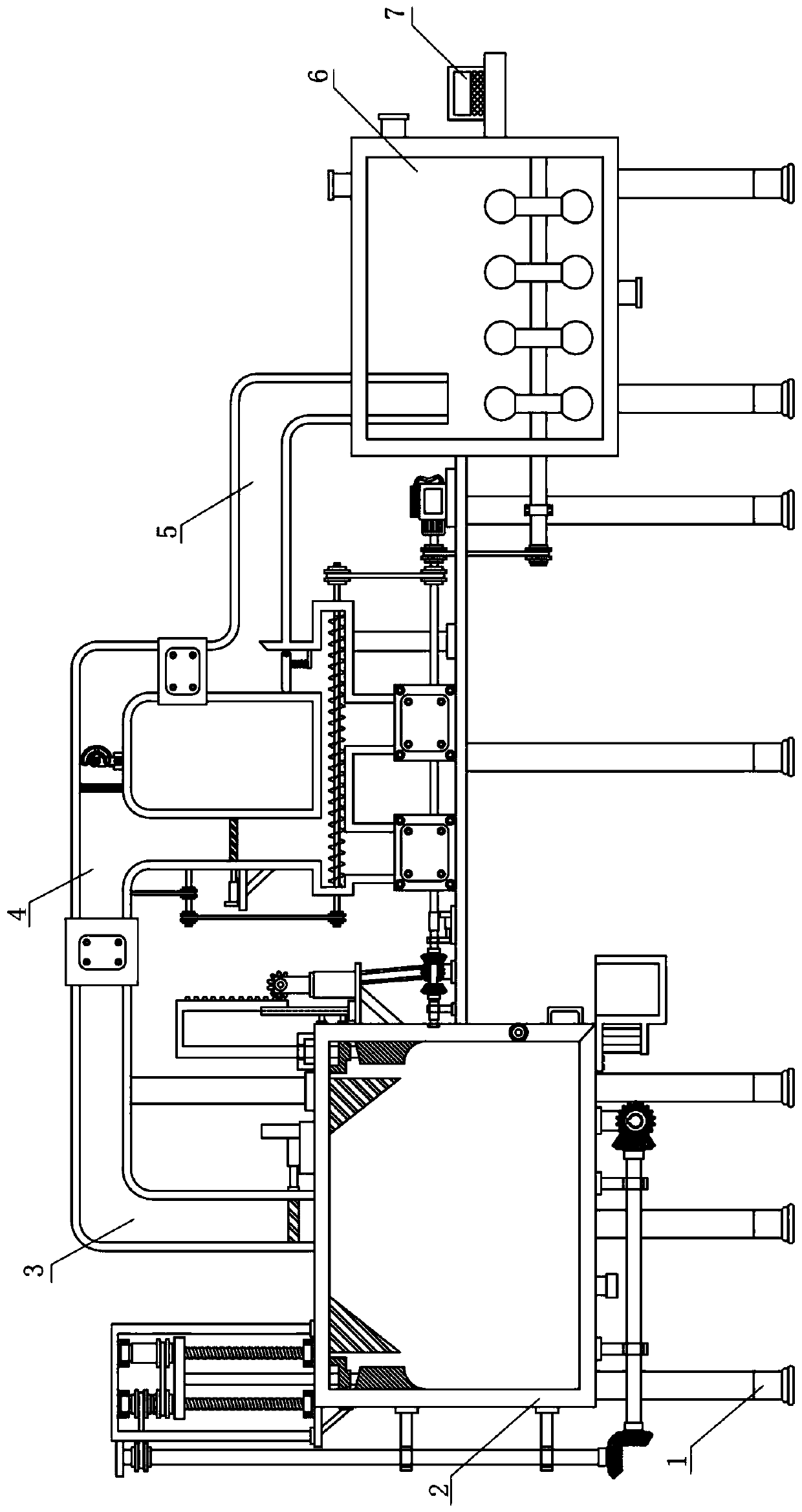

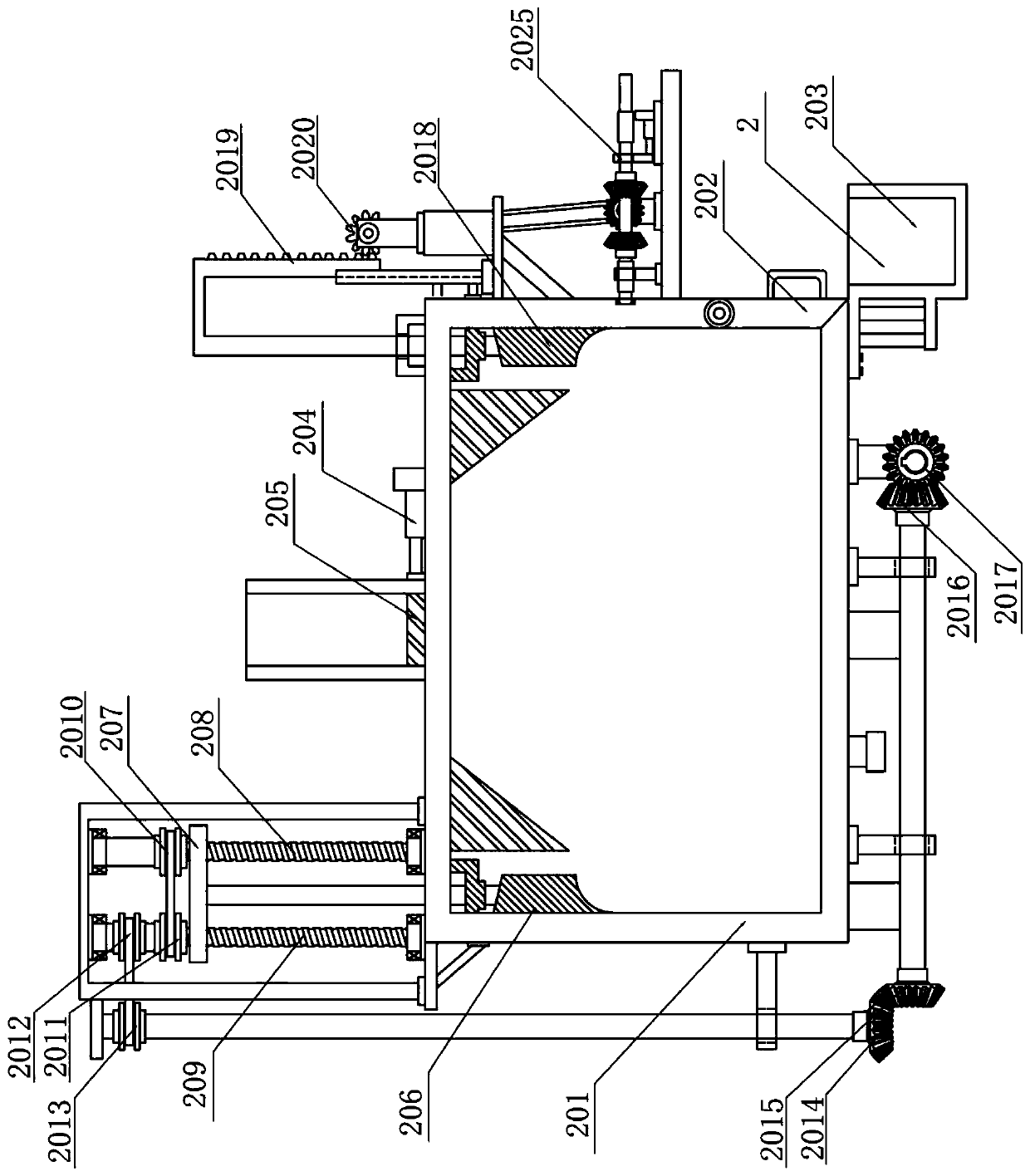

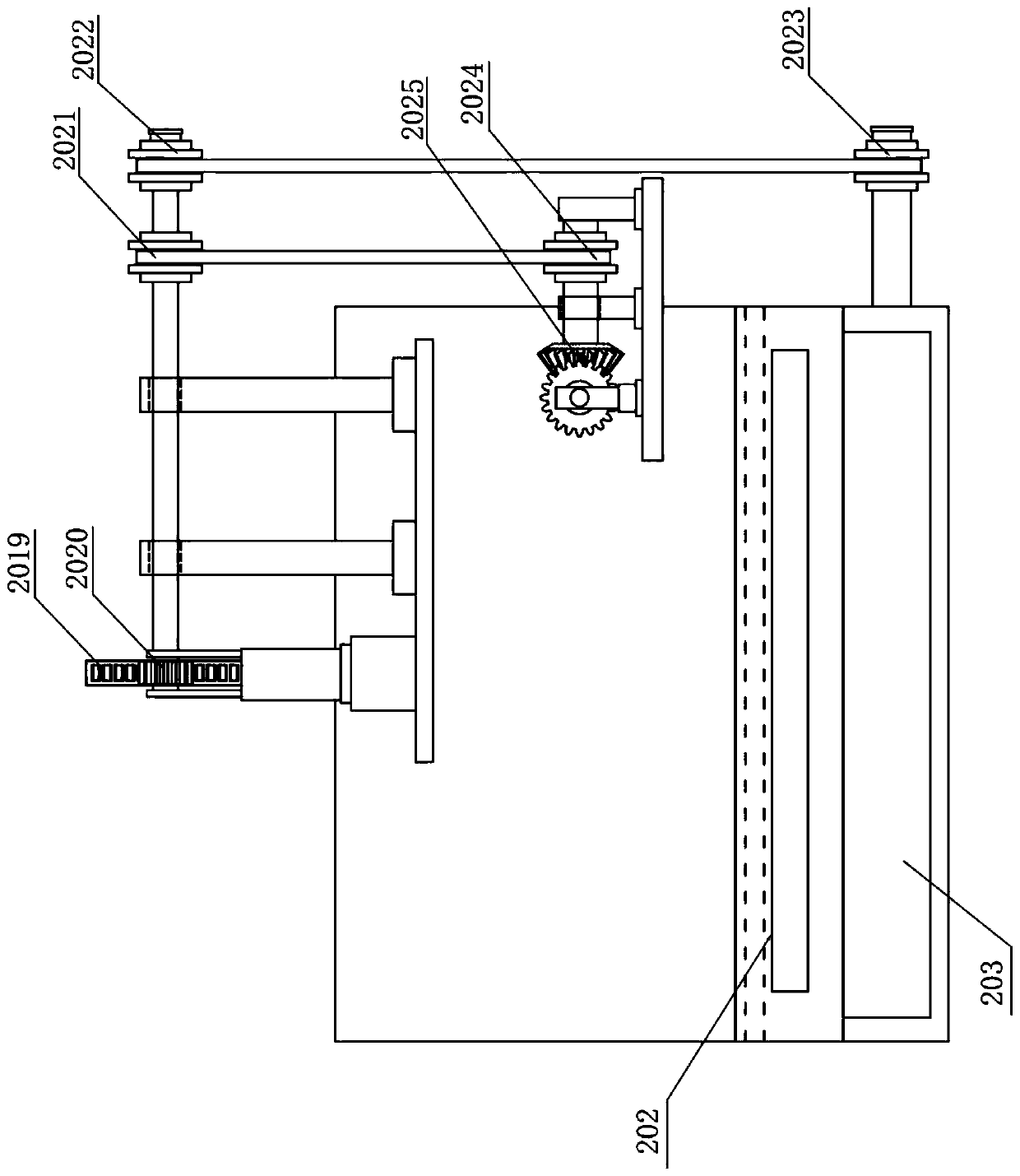

[0030] A fire retardant coating raw material preparation device, such as Figure 1-7 As shown, it includes a leg 1, a raw material preparation and recovery device 2, a first connecting pipe 3, a synchronous collection device 4, a second connecting pipe 5, an exhaust gas treatment device 6 and a control panel 7; the top of the leg 1 is connected to the raw material preparation and recycling device 2 The top middle part of the raw material preparation and recovery device 2 is connected with the first connecting pipe 3; the right middle part of the raw material preparation and recovery device 2 is connected with the tail gas treatment device 6; the right top of the first connecting pipe 3 is connected with the synchronous collection device 4, and the synchronous collection The right bottom of the device 4 is connected to the tail gas treatment device 6; the right middle part of the synchronous collection device 4 is connected to the second connecting pipe 5, and the right side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com