Supported nano multi-metal catalyst, preparation method thereof and application of supported nano multi-metal catalyst to CO oxidation

A multi-metal catalyst, supported technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of poor activity of single metal, multi-metal and perovskite It is difficult to combine the type composite oxide and the specific surface area of the perovskite type composite oxide is small to achieve the effect of good stability and sintering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

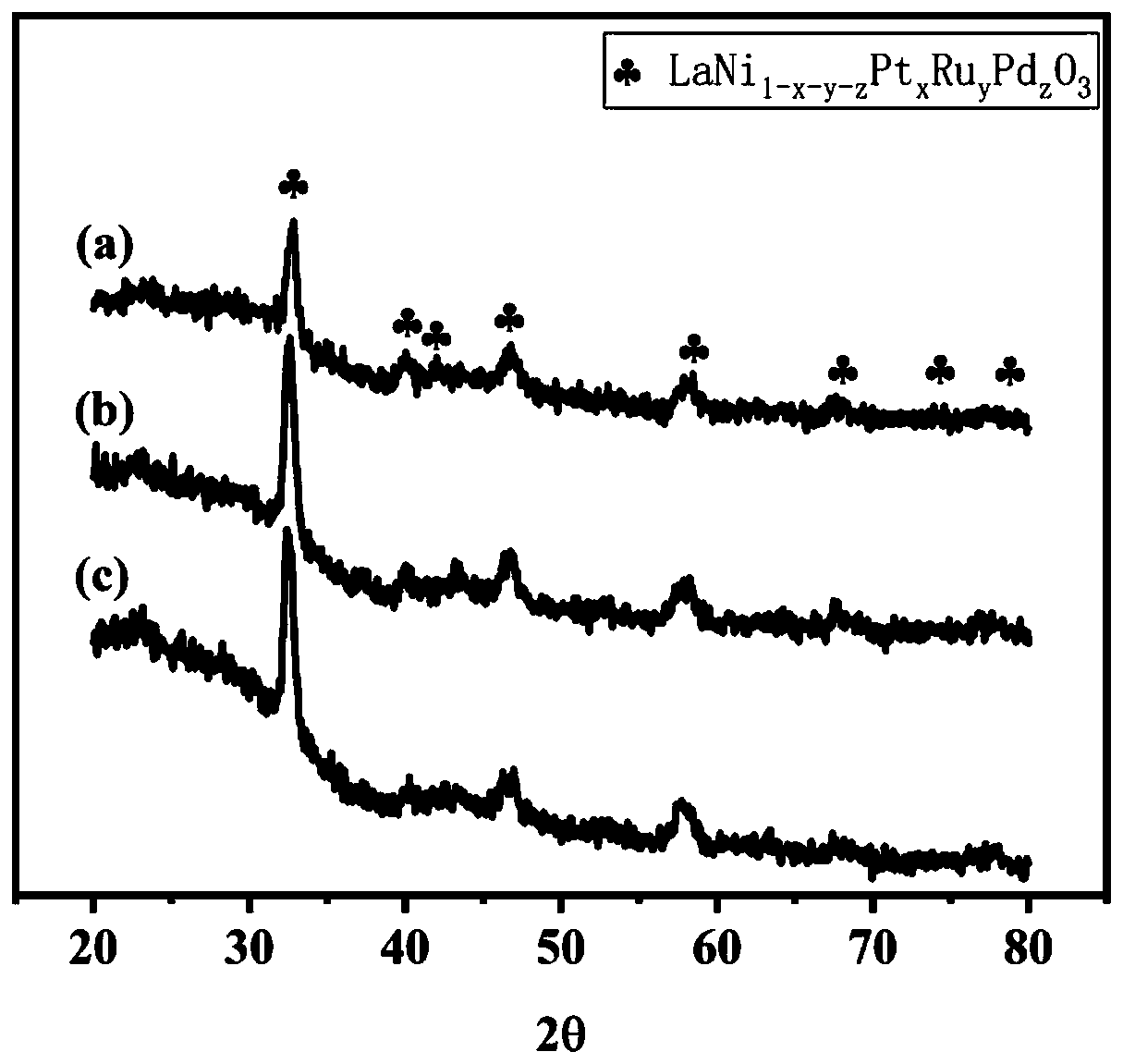

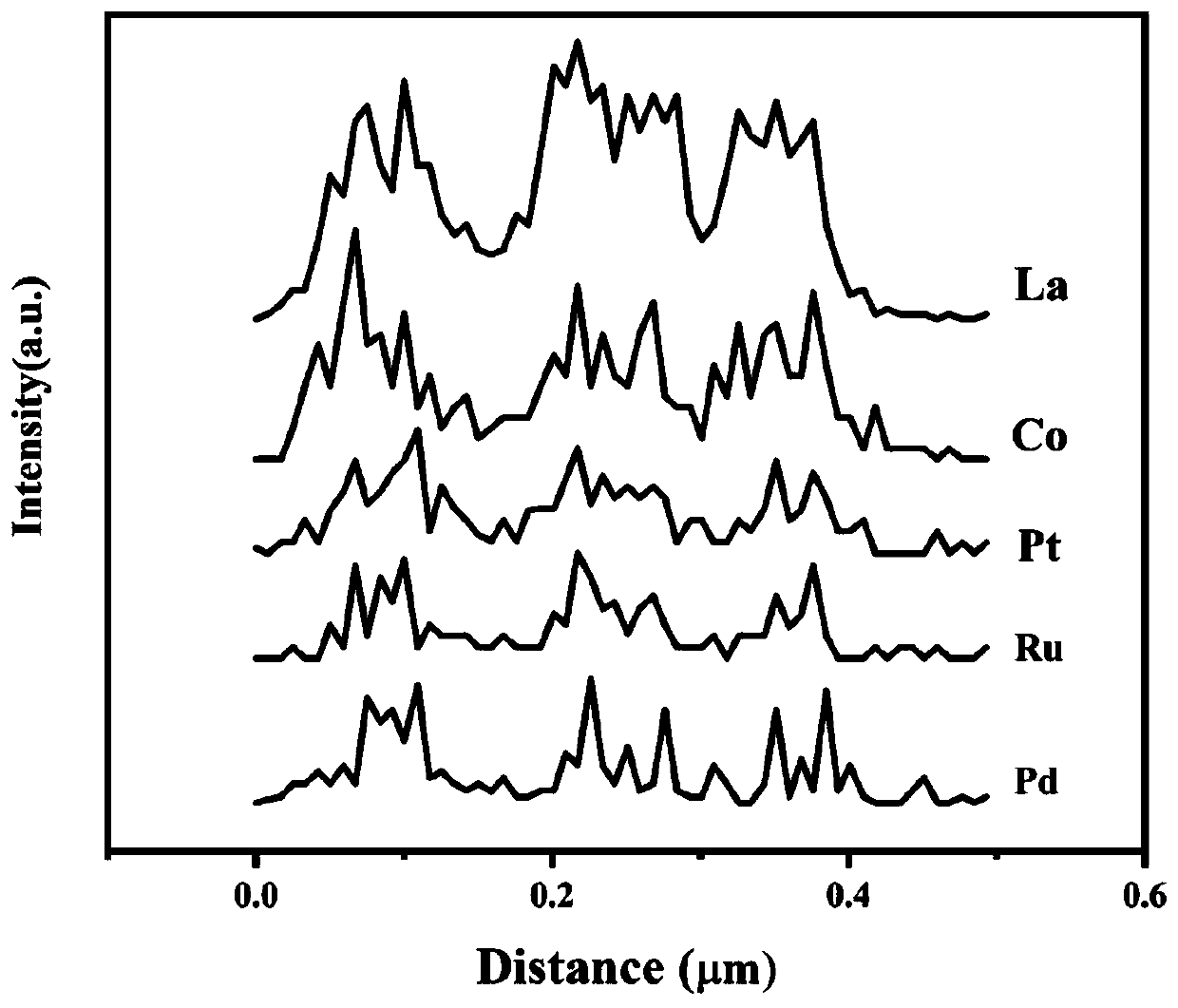

Embodiment 1

[0030] (1), promptly according to molar ratio is lanthanum nitrate: cobalt nitrate: platinum nitrate: ruthenium nitrate: palladium nitrate: citric acid: ethylene glycol=1:0.97:0.01:0.01:0.01:2.4:0.48 ratio configuration solution;( 2), that is, according to the mass fraction of perovskite in the catalyst as 10%, the solution configured in step (1) is impregnated in SiO 2 After standing on the carrier for 24 hours, the sample was placed in a constant temperature drying oven at 80°C for 6 hours to obtain an intermediate product; (3), the intermediate product obtained in step (2) was heated to 120°C and dried for 12 hours to obtain a dried product (4), the product that is about to step (3) obtains roasting 2h and 5h respectively at 300 ℃ and 600 ℃, obtains catalyst precursor LaCo 0.97 Pt 0.01 Ru 0.01 PD 0.01 o 3 / SiO 2 . (5), the catalyst precursor that is about to step (4) obtains is placed in the reactor, passes into 12000ml / (g in the reactor cat h) using hydrogen to red...

Embodiment 2

[0035] (1), promptly according to molar ratio is lanthanum nitrate: cobalt nitrate: platinum nitrate: ruthenium nitrate: palladium nitrate: citric acid: ethylene glycol=1:0.85:0.05:0.05:0.05:2.4:0.48 ratio configuration solution;( 2), that is, according to the mass fraction of perovskite in the catalyst as 10%, the solution configured in step (1) is impregnated in SiO 2 After standing on the carrier for 24 hours, the sample was placed in a constant temperature drying oven at 80°C for 6 hours to obtain an intermediate product; (3), the intermediate product obtained in step (2) was heated to 120°C and dried for 12 hours to obtain a dried product (4), the product that is about to step (3) obtains roasting 2h and 5h respectively at 300 ℃ and 600 ℃, obtains catalyst precursor LaCo 0.85 Pt 0.05 Ru 0.05 PD 0.05 o 3 / SiO 2 . (5), the catalyst precursor that is about to step (4) obtains is placed in the reactor, passes into 12000ml / (g in the reactor cat h) using hydrogen to red...

Embodiment 3

[0040] (1), promptly according to molar ratio is lanthanum nitrate: cobalt nitrate: platinum nitrate: ruthenium nitrate: palladium nitrate: citric acid: ethylene glycol=1:0.7:0.1:0.1:0.1:2.4:0.48 ratio configuration solution;( 2), that is, according to the mass fraction of perovskite in the catalyst as 10%, the solution configured in step (1) is impregnated in SiO 2 After standing on the carrier for 24 hours, the sample was placed in a constant temperature drying oven at 80°C for 6 hours to obtain an intermediate product; (3), the intermediate product obtained in step (2) was heated to 120°C and dried for 12 hours to obtain a dried product (4), the product that is about to step (3) obtains roasting 2h and 5h respectively at 300 ℃ and 600 ℃, obtains catalyst precursor LaCo 0.7 Pt 0.1 Ru 0.1 PD 0.1 o 3 / SiO 2 . (5), the catalyst precursor that is about to step (4) obtains is placed in the reactor, passes into 12000ml / (g in the reactor cat h) with hydrogen to reduce the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com