Recovery device for magnetic abrasive particles

A technology of magnetic abrasive particles and recovery device, which is applied in the directions of grinding/polishing safety device, magnetic separation, grinding/polishing equipment, etc. Easy to operate, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the specific embodiment of the invention is further described:

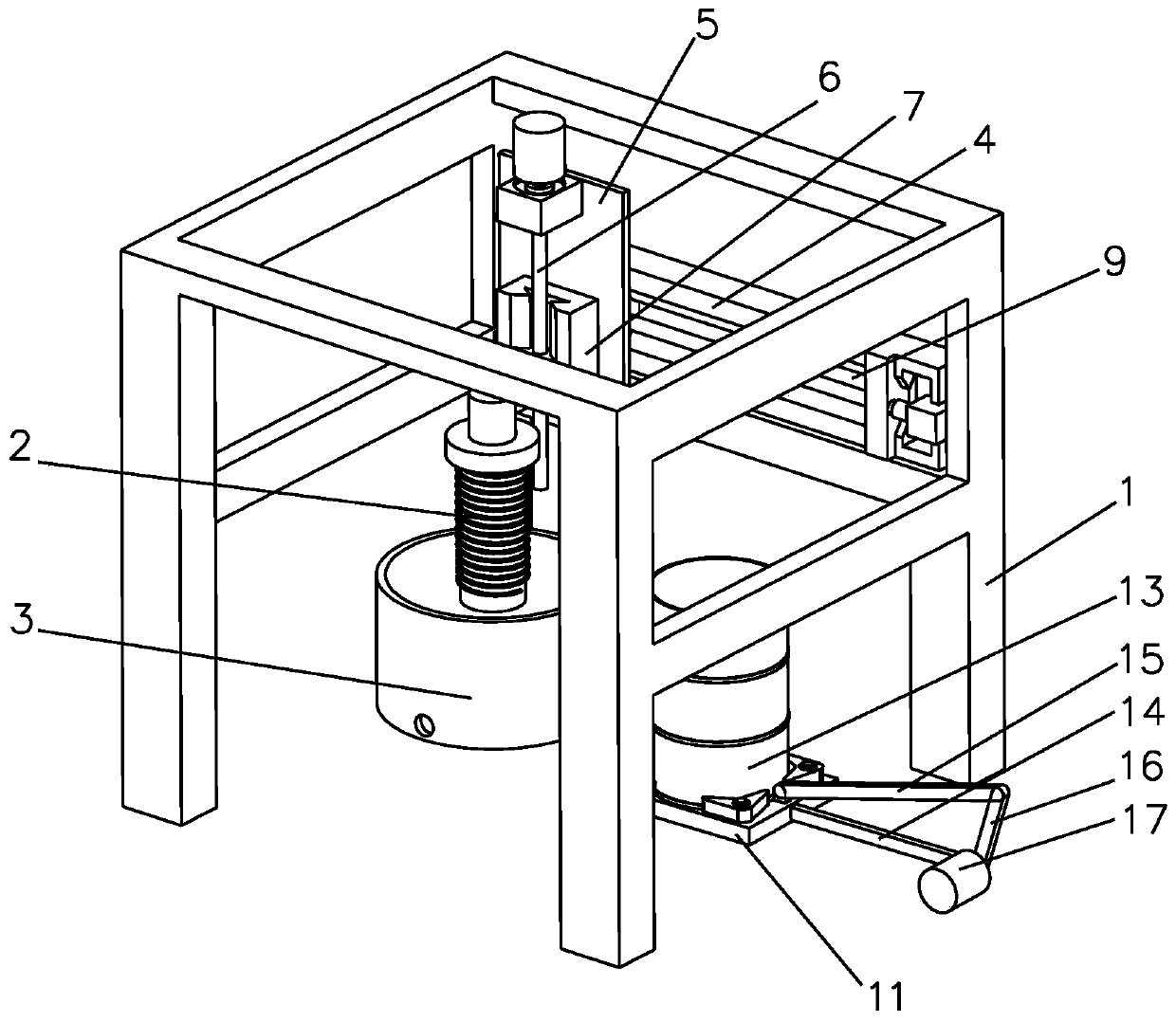

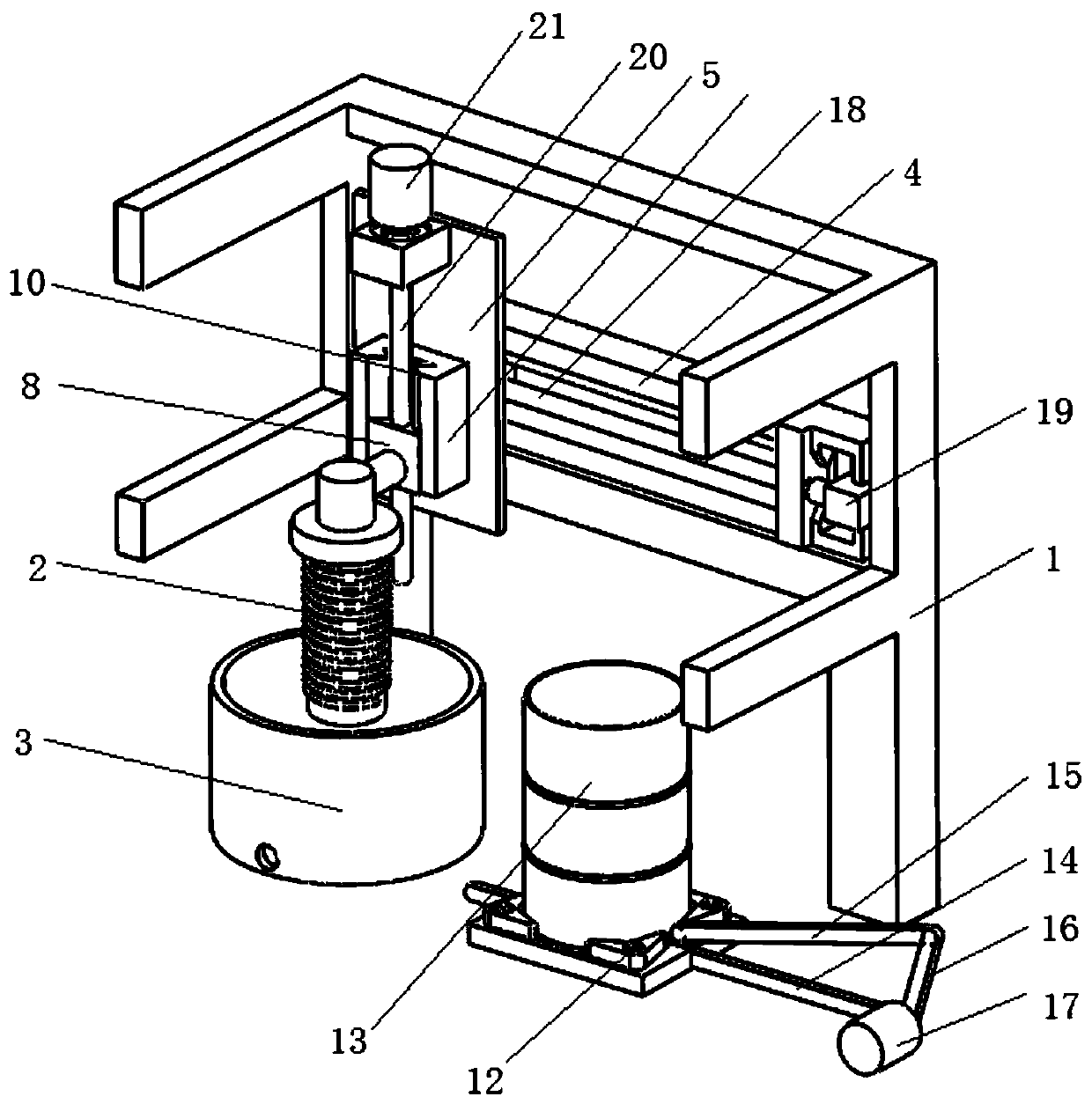

[0025] Such as Figure 1-Figure 2 , a magnetic abrasive recovery device, including a bracket 1, a sliding mechanism, an electromagnet 2, a flushing pool 3, and a screening mechanism. The flushing pool 3 and the screening mechanism are arranged inside the bracket 1, and the sliding mechanism is arranged on the bracket 1.

[0026] The sliding mechanism includes a transverse slide rail 4, a slide plate 5, a first screw drive mechanism 6, a bearing 7, a slider 8, and a second lead screw drive mechanism 9. The transverse slide rail 4 is arranged on the support 1, and the slide plate 5 passes through the first The first screw drive mechanism 6 is driven to slide laterally on the horizontal slide rail 4 , and the first screw drive mechanism 6 includes a first screw drive mechanism 18 and a first screw motor 19 .

[0027] The slide plate 5 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com