Green and environment-friendly cement and preparation method thereof

A green and environmentally friendly cement and cement clinker technology, which is applied in the field of cement manufacturing, can solve the problems of complex components and weak effects, and achieve the effects of promoting sintering reaction, improving the utilization of waste materials, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

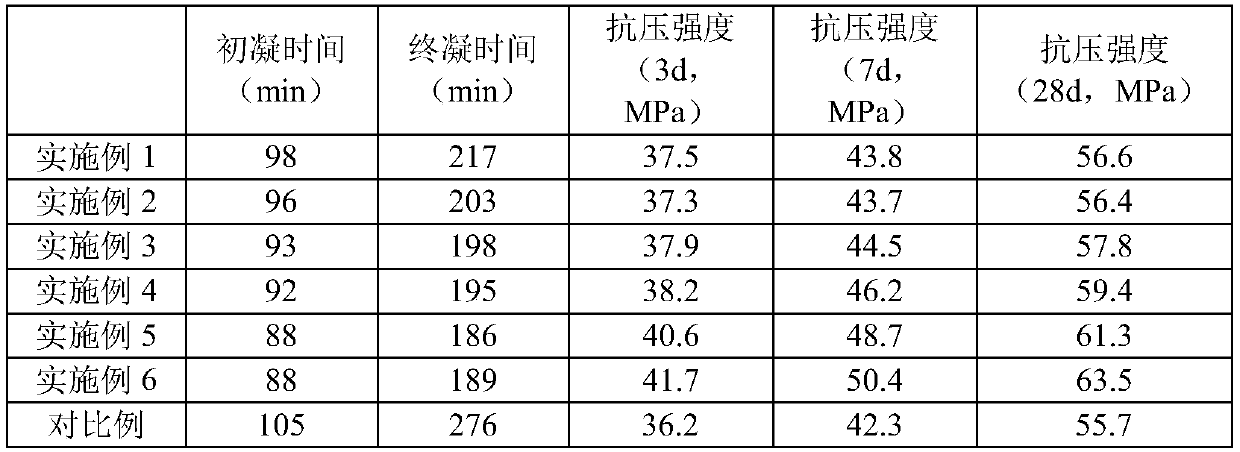

Examples

preparation example Construction

[0045] The preparation method of the green environmental protection cement of the present invention comprises the following steps: 1) mixing and grinding the raw materials of cement clinker to obtain raw meal, then preheating and decomposing the raw meal, and then sintering at 1350-1450°C for 20- 30 minutes, rapid cooling to obtain cement clinker; 2) mixing and grinding the cement clinker prepared in step 1) with the admixture material to obtain final product.

[0046] In step 1), mixing and grinding the raw materials of cement clinker is to uniformly mix limestone, sandstone, sulfuric acid slag, coal gangue, and iron slag to obtain a premix, and then powder the premix to obtain raw meal. Specifically, the limestone crushed material, coal gangue crushed material and sandstone are mixed to obtain the first mixed material; the sulfuric acid slag and iron ore slag are mixed uniformly to obtain the second mixed material, and then the first mixed material and the second mixed materi...

Embodiment 1

[0052] The green environmental protection cement of this embodiment is made by mixing cement clinker and admixture according to the weight ratio of 70:30. The cement clinker is made from the following raw materials: limestone 155.0kg, sandstone 13.0kg, sulfuric acid slag 4.0kg, coal gangue 8.0kg, iron slag 3.0kg. The mixed material is composed of limestone, fly ash, desulfurized gypsum and iron slag in a weight ratio of 10:18:12:9.

[0053] Wherein, the mass percentage of CaO in limestone is 49.22%.

[0054] The preparation method of the green environment-friendly cement of the present embodiment comprises the steps:

[0055] 1) Pulverizing and screening the limestone to obtain limestone granules; pulverizing and sieving coal gangue to obtain coal gangue granules; then uniformly mixing the limestone granules, coal gangue granules and sandstone to obtain a mixture;

[0056] Mix sulfuric acid slag and iron ore slag evenly to obtain the second mixture;

[0057] Then the first ...

Embodiment 2

[0062] The green environmental protection cement of this embodiment is made by mixing cement clinker and admixture according to the weight ratio of 70:30. The cement clinker is made from the following raw materials: limestone 160.0kg, sandstone 13.5kg, sulfuric acid slag 4.5kg, coal gangue 9.0kg, iron ore slag 3.5kg, construction waste 15.0kg, barium slag 3.0kg. The mixed material is composed of limestone, fly ash, desulfurized gypsum and iron slag in a weight ratio of 10:18:12:9.

[0063] Wherein, the mass percentage of CaO in limestone is 49.22%.

[0064] The preparation method of the green environment-friendly cement of the present embodiment comprises the steps:

[0065] 1) Pulverizing and screening the limestone to obtain limestone granules; pulverizing and sieving coal gangue to obtain coal gangue granules; then uniformly mixing the limestone granules, coal gangue granules and sandstone to obtain the first mixture;

[0066] Mix sulfuric acid slag, iron ore slag, and ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com