Green separation and extraction method of soybean 7S globulin and 11S globulin

An extraction method and soybean protein technology, which are applied in chemical instruments and methods, peptide preparation methods, plant peptides, etc., can solve the problems of large use of chemical reagents, weaken market competitiveness, increase economic burden, etc., and avoid large-scale use. , The effect of simplifying the production process and reducing the degree of denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Degreased soybean meal is pulverized to obtain defatted soybean flour. Add distilled water to the defatted soybean flour at a solid-to-liquid ratio of 1:10. After shaking in a water bath at 45°C for 1 hour, centrifuge at 11,000 g / min for 20 minutes, and extract the supernatant as soybean protein. liquid;

[0032] (2) Freezing the soybean protein extract obtained in (1) at -20°C for 3 days;

[0033] (3) Place the frozen liquid obtained in (2) at 10°C until it completely melts;

[0034] (4) Centrifuge the melt solution obtained in (3) at 11000g / min for 10min, and collect the supernatant and precipitate respectively;

[0035] (5) Combine all the supernatants obtained by centrifugation in (4), add distilled water to shake the precipitate at a solid-to-liquid ratio of 1:5, and continue to freeze;

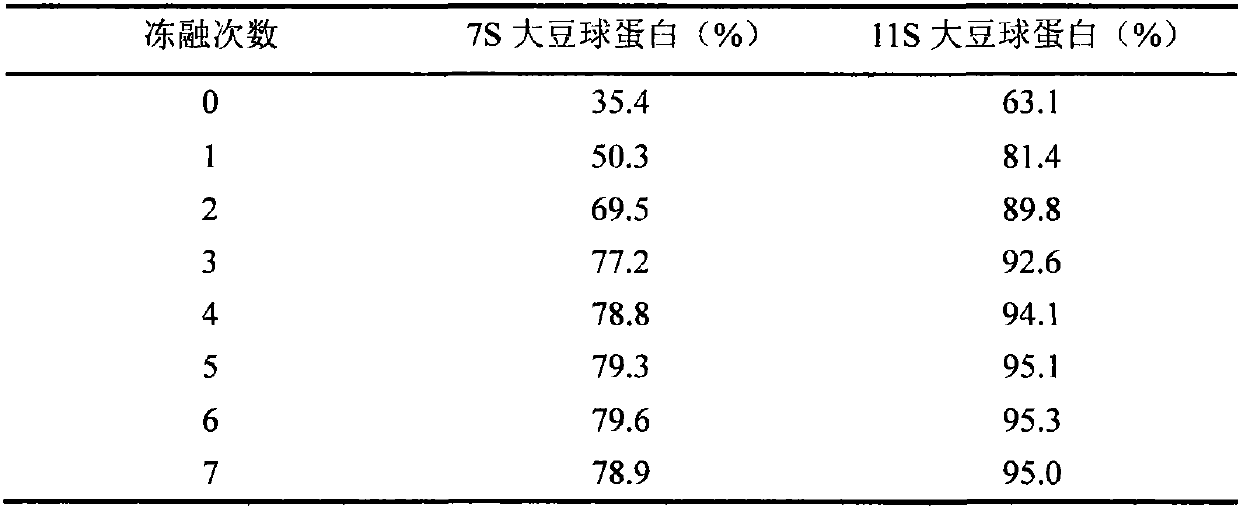

[0036] (6) Repeat steps (2) to (5), the number of repetitions is 5 times, and the gradient cooling is set to maintain 15 minutes for every 5°C drop;

[0037] (7) The thawed...

Embodiment 2

[0042] (1) Grinding defatted soybean meal to obtain defatted soybean flour, adding distilled water to the defatted soybean flour at a solid-to-liquid ratio of 1:80, shaking in a water bath at 40°C for 1 hour, centrifuging at 8000g / min for 20min, and using the supernatant as soybean protein Extraction solution;

[0043] (2) Place the soybean protein extract obtained in (1) at -5°C and freeze for 2 days;

[0044] (3) Place the frozen liquid obtained in (2) at 4°C until it completely melts;

[0045] (4) Centrifuge the melt solution obtained in (3) at 11000g / min for 10min, and collect the supernatant and precipitate respectively;

[0046] (5) Combine all the supernatants obtained by centrifugation in (4), add distilled water to shake the precipitate at a solid-to-liquid ratio of 1:5, and continue to freeze;

[0047] (6) Repeat steps (2) to (5), the number of repetitions is 3 times, and the temperature dropped by the gradient is 5°C;

[0048] (7) Centrifuge the thawed solution o...

Embodiment 3

[0050](1) Grinding defatted soybean meal to obtain defatted soybean flour, adding distilled water to the defatted soybean flour at a solid-to-liquid ratio of 1:6, shaking in a water bath at 60°C for 3 hours, centrifuging at 11,000 g / min for 20 minutes, and using the supernatant as soybean protein Extraction solution;

[0051] (2) Freezing the soybean protein extract obtained in (1) at -80°C for 1 day;

[0052] (3) Place the frozen liquid obtained in (2) at 20°C until it completely melts;

[0053] (4) Centrifuge the melt solution obtained in (3) at 8000g / min for 10min, and collect the supernatant and precipitate respectively;

[0054] (5) Combine all the supernatants obtained by centrifugation in (4), add distilled water to shake the precipitate at a solid-to-liquid ratio of 1:4, and continue to freeze;

[0055] (6) Repeat steps (2) to (5), the number of repetitions is 5 times, and the temperature dropped by the gradient is 5°C;

[0056] (7) Centrifuge the thawed solution ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com