Tartary buckwheat white spirit and brewing process thereof

A technology, the technology of tartary buckwheat, applied in the field of tartary buckwheat liquor and its brewing technology, can solve the problems of low liquor yield, difficulty in mechanized production, difficult acid production, etc., and achieve the goal of increasing liquor yield, sweetness and aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

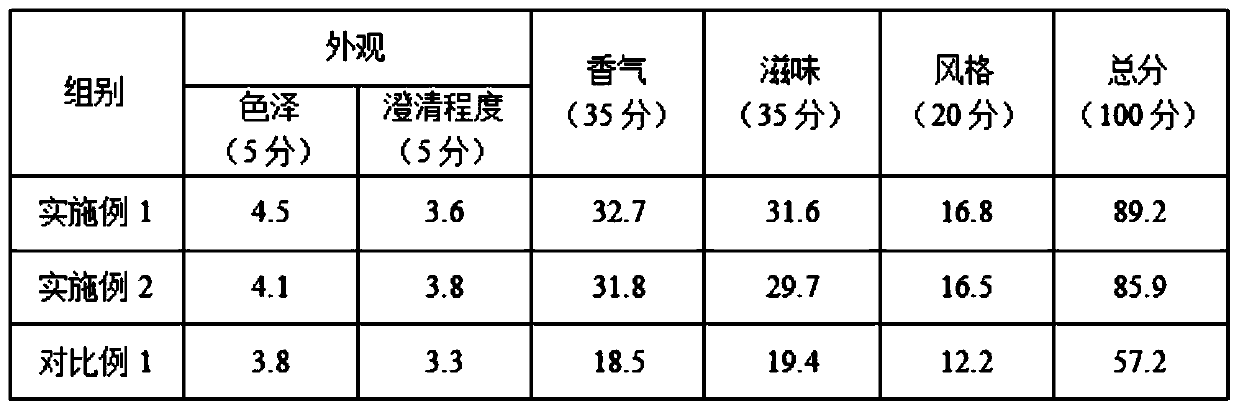

Embodiment 1

[0032] A brewing process of tartary buckwheat liquor includes the following steps:

[0033] (1) Preparation of raw materials: select fresh, mildew-free, and impurity-free tartary buckwheat rice grains as raw materials, pulverize and pass through a 40-mesh sieve to obtain tartary buckwheat flour for use;

[0034] (2) To adjust the emulsion: add 8 times the amount of citric acid solution to the tartary buckwheat powder and stir for 1 hour to form a tartary buckwheat powder emulsion;

[0035] (3) Drum maturation: Put the tartary buckwheat powder emulsion in step (2) in a double drum dryer, adjust the temperature to 150°C, and adjust the film thickness of the tartary buckwheat powder emulsion to 1mm. After drying, collect the starch layer and pulverize Pass a 40-mesh sieve to obtain gelatinized tartary buckwheat starch;

[0036] (4) Adjust the pH value: add 1.5 times the amount of distiller's grain liquid to the gelatinized tartary buckwheat starch of step (3), and adjust the pH to 5 with...

Embodiment 2

[0040] A brewing process of tartary buckwheat liquor includes the following steps:

[0041] (1) Preparation of raw materials: select fresh, mildew-free, and impurity-free tartary buckwheat rice grains as raw materials, pulverize and pass through a 40-mesh sieve to obtain tartary buckwheat flour for use;

[0042] (2) To adjust the emulsion: add 6 times the amount of citric acid solution to the tartary buckwheat powder and stir for 1 hour to form a tartary buckwheat powder emulsion;

[0043] (3) Drum maturation: Put the tartary buckwheat powder emulsion of step (2) in a double drum dryer, adjust the temperature to 160℃, and adjust the film thickness of the tartary buckwheat powder emulsion to 1mm. After drying, collect the starch layer and pulverize Pass a 40-mesh sieve to obtain gelatinized tartary buckwheat starch;

[0044] (4) Adjust the pH value: add 1.5 times the amount of distiller's grain liquid to the gelatinized tartary buckwheat starch of step (3), and adjust the pH to 5 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com