Anti-interference integrated microwave heating element used in vacuum state

A technology of microwave heating and vacuum state, which is applied in the field of anti-interference integrated microwave heating components, can solve the problems affecting the large-scale equipment, increasing the energy consumption of the equipment, and the inability of the magnetron to work, so as to reduce the volume of the equipment, avoid the current attenuation, simplify the The effect of device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

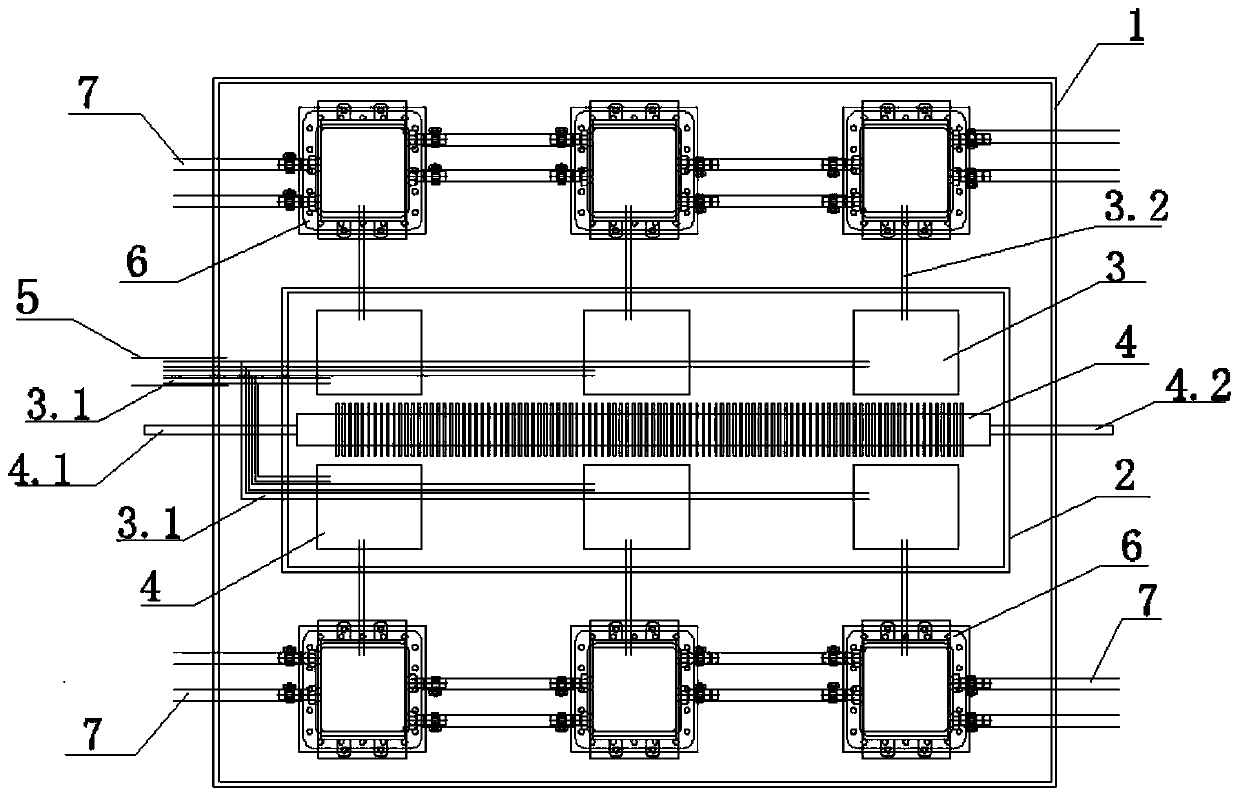

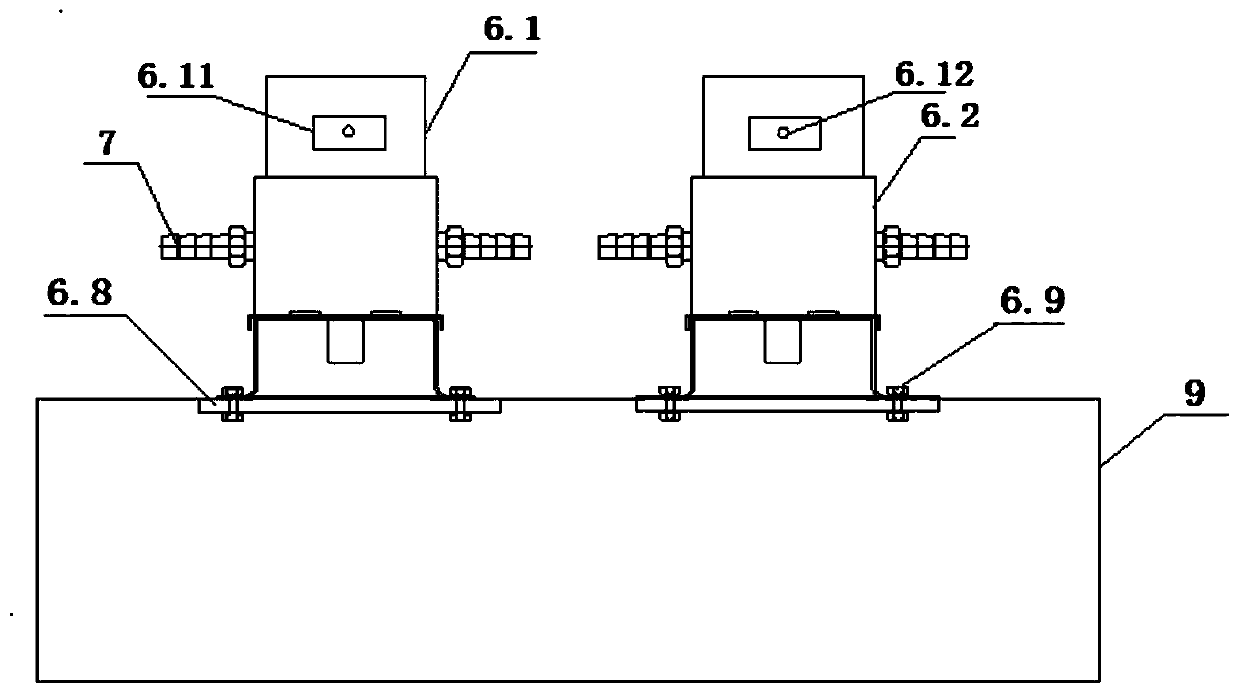

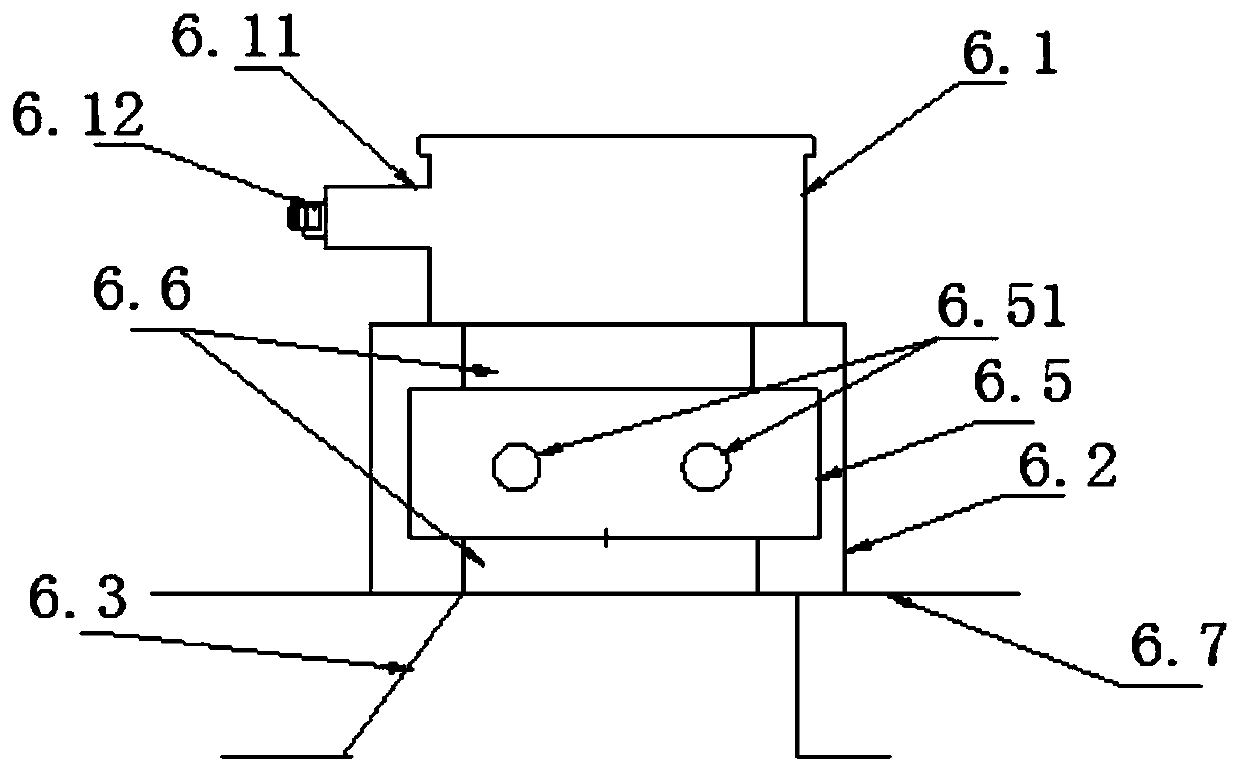

[0030] like Figure 1~6 The shown integrated microwave heating element for anti-interference in a vacuum state, the integrated microwave element is arranged outside the microwave heating resonant cavity in the vacuum tank 8, it includes a closed shielding box 1, and the shielding box 1 includes a microwave power supply assembly and The magnetron assembly; the microwave power supply assembly includes a microwave power supply oil tank 2, a microwave power supply 3 and an oil cooling heat exchanger 4 are arranged in the microwave power supply oil tank 2, and one end of each microwave power supply 3 is provided with a power control compound line 3.1, and a power control compound line 3.1 The other end protrudes from the microwave power supply oil tank 2 and the shielding box 1 and enters the normal pressure environment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com