Bearing vibration measuring device based on optical interference principle and measuring method thereof

A technology of bearing vibration and measuring devices, which is applied in the directions of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of low measurement accuracy and unsatisfactory high-speed measurement, and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

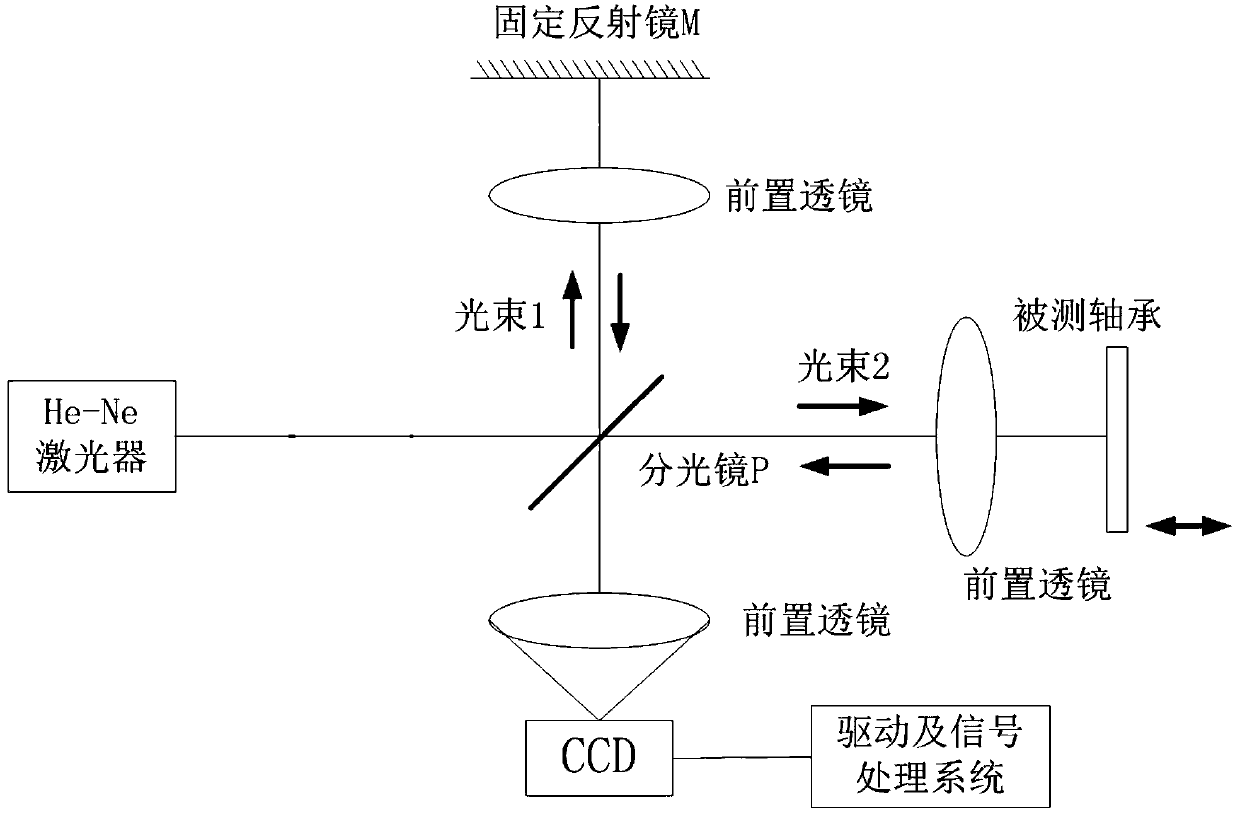

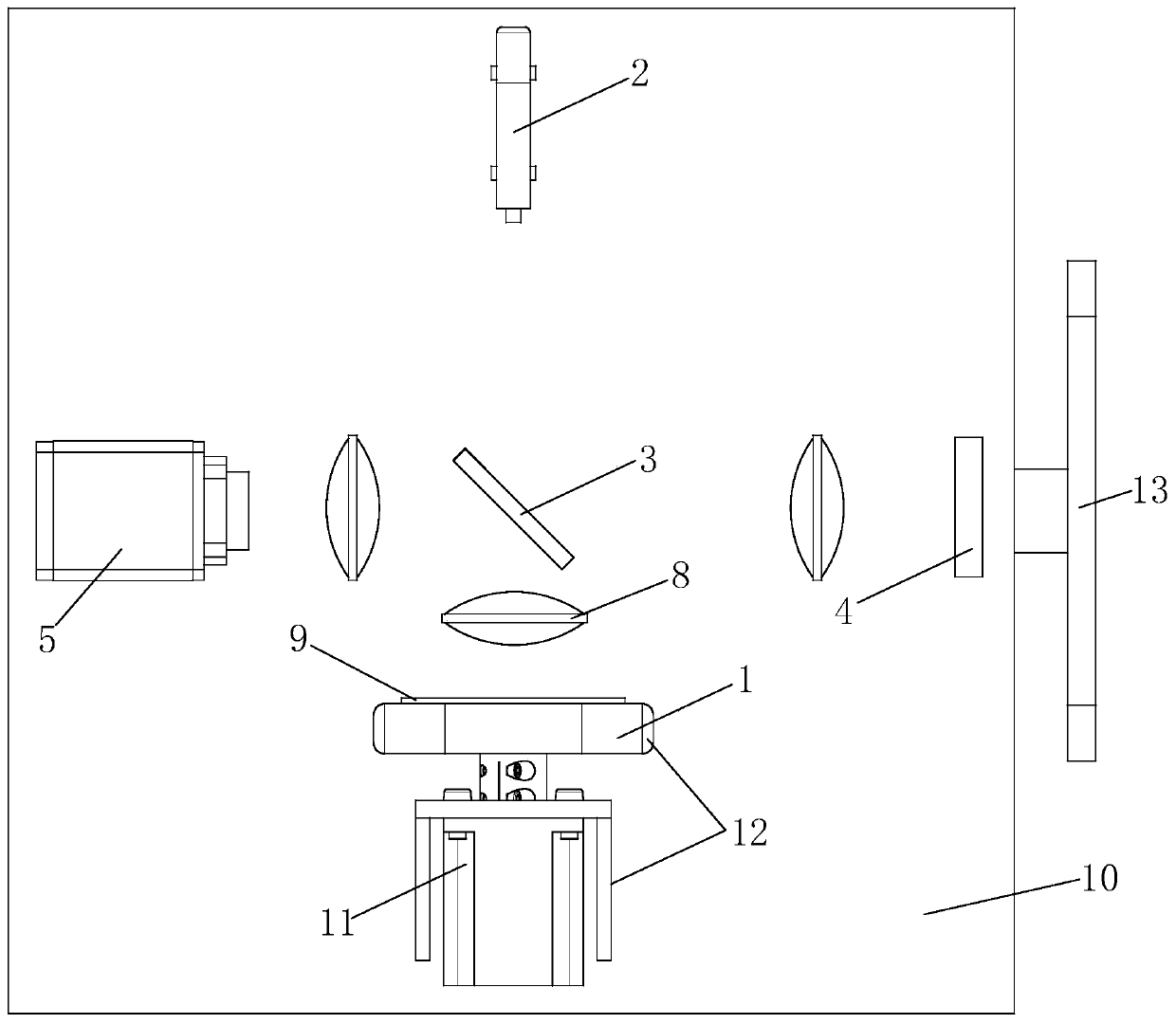

[0054] see figure 1 , figure 2 as well as image 3 , this embodiment provides a bearing vibration measuring device based on the principle of optical interference, the measuring device is used to measure the mechanical vibration displacement of the bearing 1 to be tested. The measuring device can be used as a detection device in the bearing quality measurement, and can judge the quality of the bearing by detecting the vibration displacement generated by the bearing during high-speed motion. It can also be used as an experimental device for the bearing detection test. It can also be used as a measuring device for bearing maintenance. The measurement device includes a laser 2, a beam splitter 3, a reflector 4, a charge-coupled device 5 and a signal processing system, and may also include a front lens 8, a reflector 2 9, a test platform 10, a bearing-driven positioning mechanism and a display screen 13 .

[0055] The laser 2 is used to emit a laser beam to the bearing 1 to be...

Embodiment 2

[0068] see Figure 4-7 , this embodiment provides a bearing vibration measuring device based on the principle of optical interference, and the device is added an optical isolator on the basis of Embodiment 1. The optical isolator is arranged between the laser 2 and the beam splitter 3 , and is used for allowing the laser beam to pass through and preventing the beam on one side of the beam splitter 3 from returning to the laser 2 . In this embodiment, the optical isolator includes a polarizer 6 and a wave plate 7 . Both the polarizer 6 and the wave plate 7 are located on the moving path of the laser beam, and the polarizer 6 is arranged between the laser 2 and the wave plate 7 . Wherein, the wave plate 7 is a 1 / 4 wave plate.

[0069] The optical isolator of the bearing vibration measurement device based on the principle of optical interference can effectively prevent the measured object and the reference optical path from returning to the laser 2 to interfere with the output of...

Embodiment 3

[0071] This embodiment provides a bearing production system, which includes the bearing vibration measuring device based on the principle of optical interference in Embodiment 1 or Embodiment 2, and also includes an alarm device and a controller. The controller is used for judging whether the displacement measured by the signal processing system is greater than a preset displacement. When the displacement is greater than the preset displacement, the controller will drive the alarm device to send an alarm message to remind the production personnel that the vibration displacement of the bearing is too large, and stop the motor 11 from rotating. When the displacement is not greater than the preset displacement, the controller draws the continuously generated displacement as a measurement curve and displays it on the display screen 13, and also judges whether the measurement time reaches a preset time. When the measurement time reaches a preset time, the controller stops the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com