Experimental system for measuring convective mass transfer coefficient and measuring method

A convective mass transfer and experimental system technology, applied in the field of heat and mass exchange equipment, can solve problems such as difficult to accurately calculate water evaporation loss and heat dissipation loss, unable to measure convective mass transfer coefficient, and difficult to directly measure mass transfer flux, etc., to achieve design Concise, easy to operate, accurate effect of convective mass transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

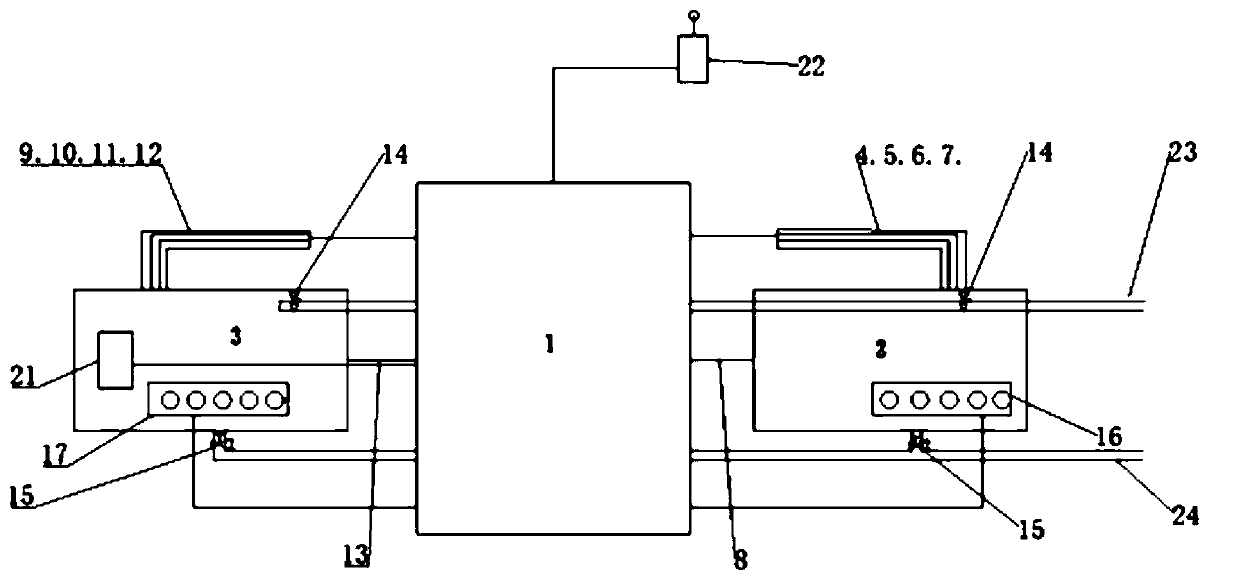

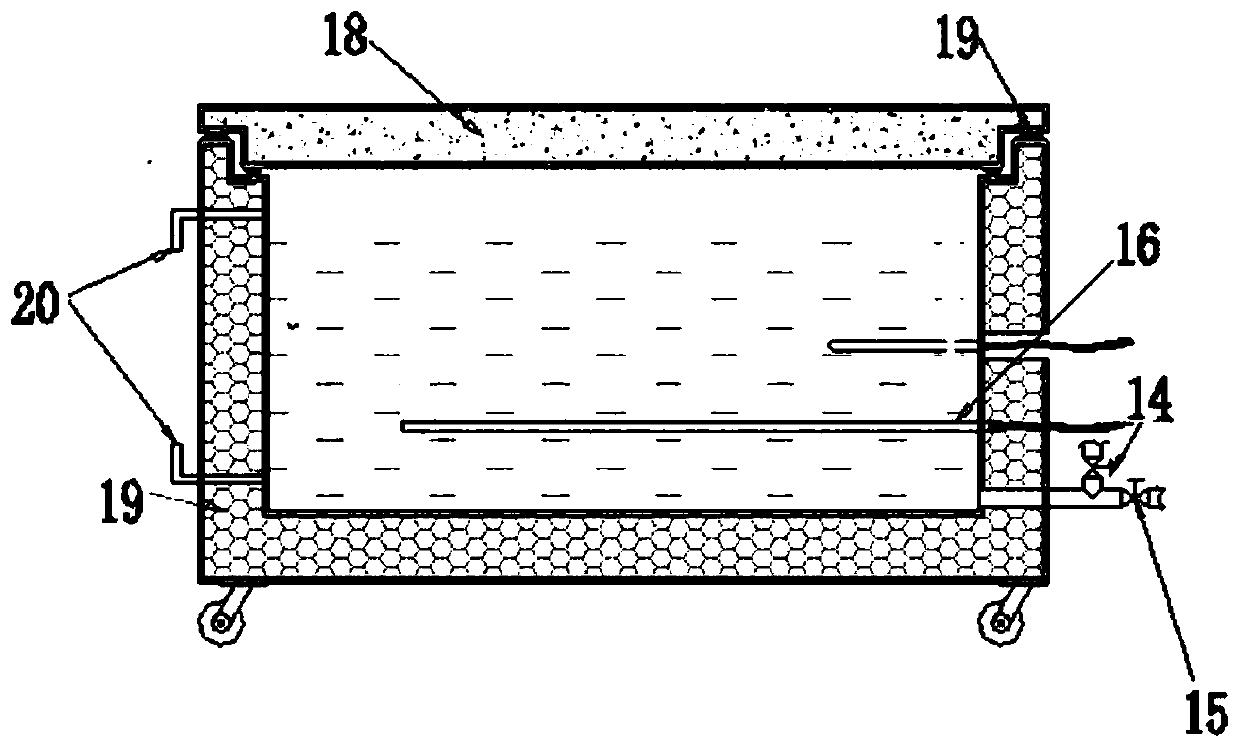

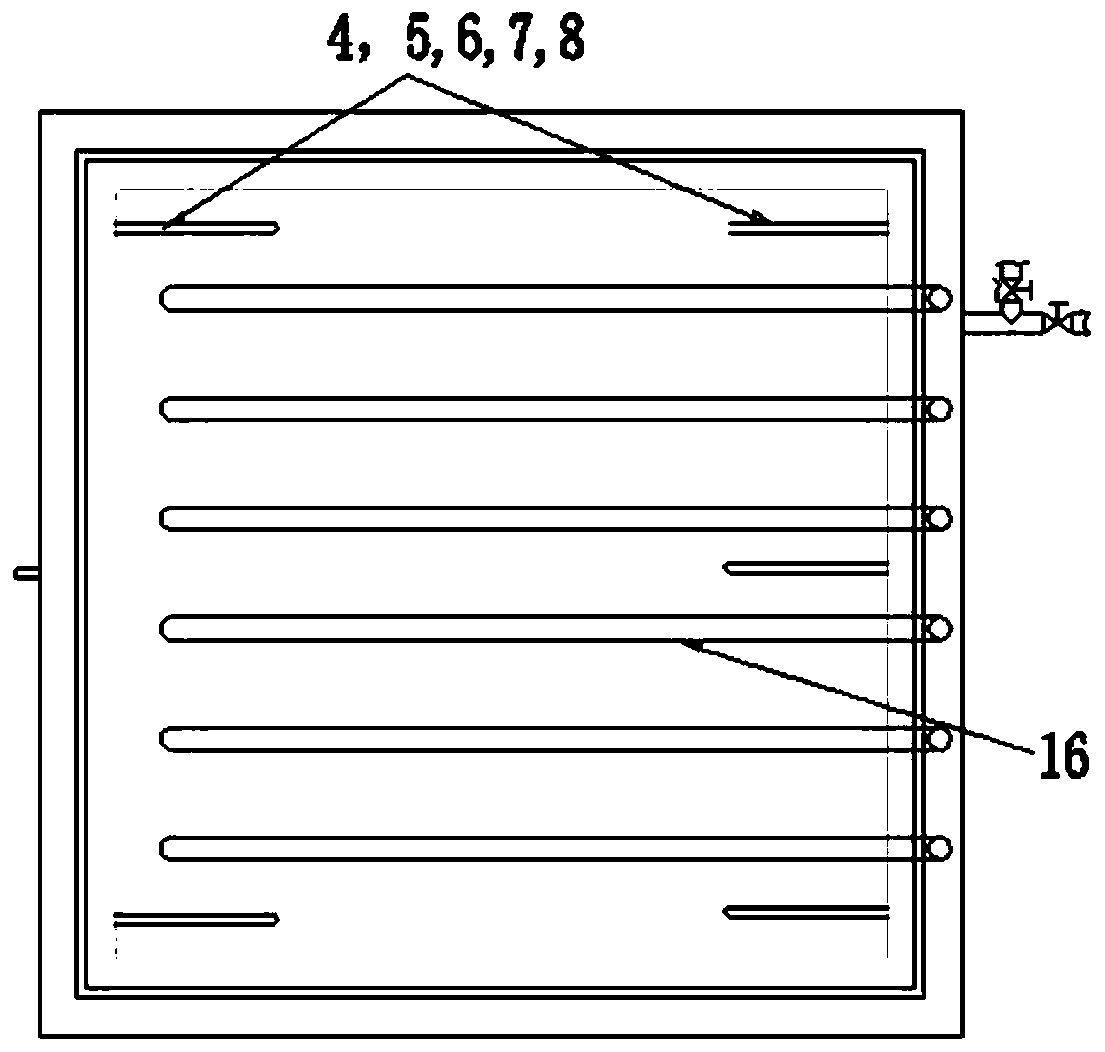

[0075] In the experimental device of the convective mass transfer coefficient of the present invention, the water temperature of the two water tanks is first heated to the same temperature by an electric heater, and then the heat preservation is carried out, and the measurement time is customized, and the power consumption of the two water tanks during this period is tested respectively. The closed water tank only exchanges sensible heat with the surrounding air. Therefore, the electric heating power of the closed water tank is the sensible heat dissipation of the closed water tank. The sensible heat transfer between the open water tank and the surrounding air is equal to the sensible heat exchange of the closed water tank, so the latent heat dissipation of the open water tank is the difference between the two powers, so the convective mass of the open water tank can be calculated, from the surface of the open water tank The average temperature is found to be the saturated wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com