Heater structure, preparation method thereof and hydrogen sensor

A heating structure and heater technology, applied in the direction of heating element materials, ohmic resistance heating parts, material resistance, etc., can solve the problems of small heater structure size, bad influence of heating structure detection accuracy, difficulty in forming the shape of resistance structure, etc. , to achieve the effect of reducing the difficulty of forming, improving the detection accuracy, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

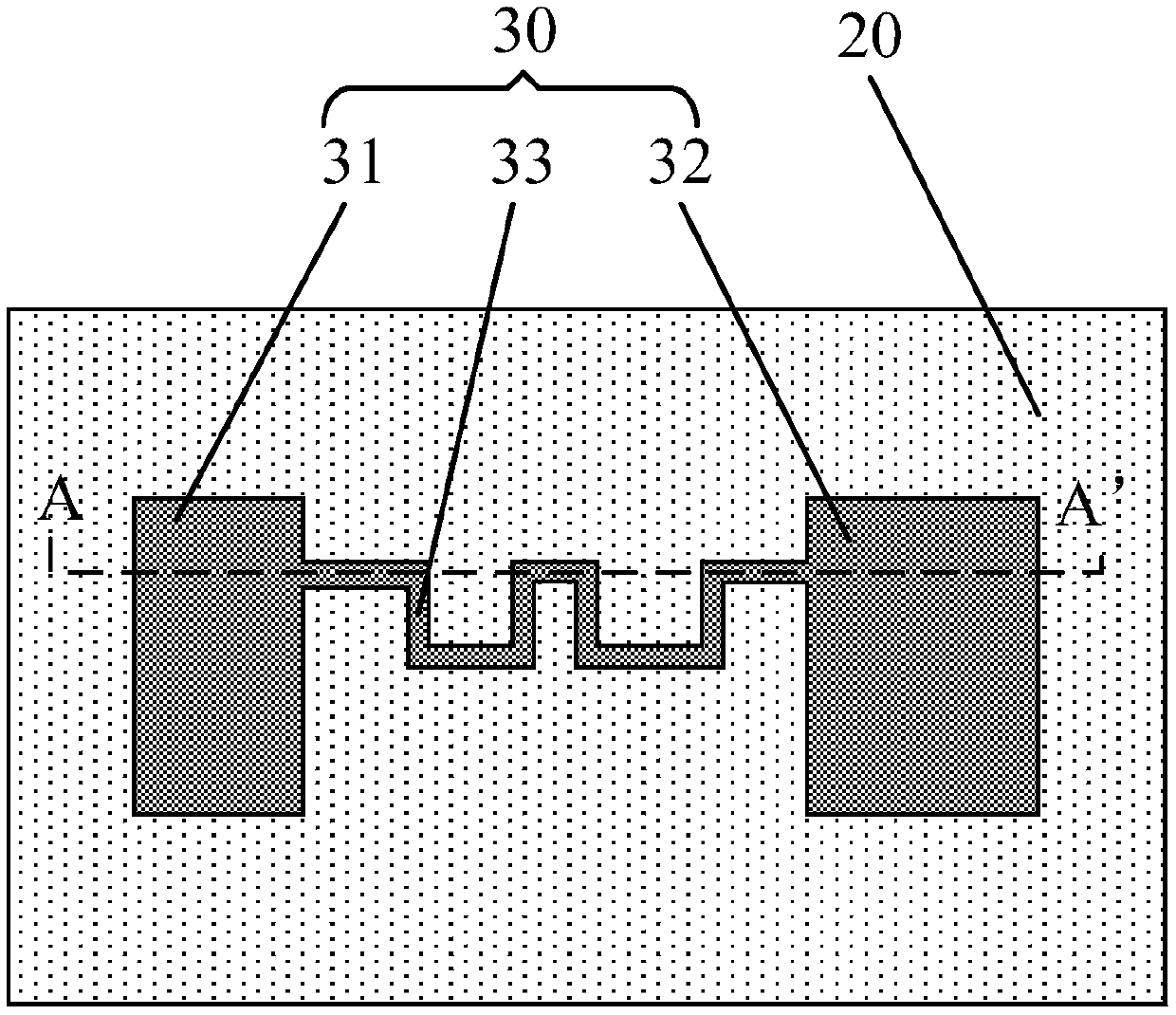

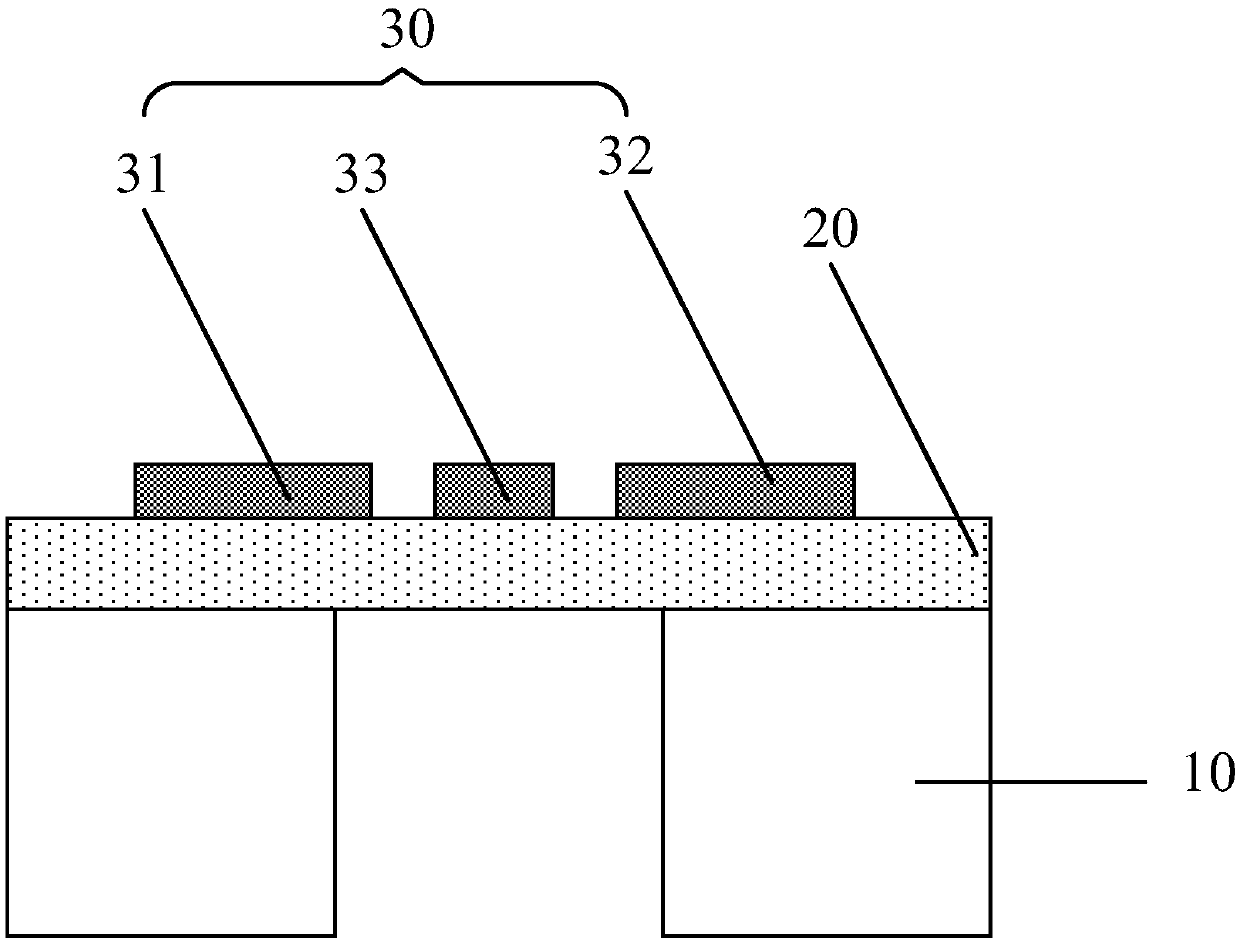

[0044] References to Heater Structures in the Prior Art figure 1 and figure 2 , figure 1 It is a top view structural schematic diagram of a heater structure in the prior art, figure 2 is a schematic cross-sectional structure diagram of a heater structure in the prior art, Figure 3-Figure 5 It is a schematic diagram of the preparation process of the heater structure. First, an initial wafer is provided as the substrate 10; an insulating film 20 is deposited on the substrate 10, and then a pattern of the heating structure 30 is printed on the insulating film 20 by a screen printing process, so that The heating structure includes a first pad 31, a second pad 32 and a resistance wire 33 connecting the first pad 31 and the second pad 32; finally, the back side of the substrate 10 is etched to form a through holes.

[0045] However, as mentioned in the background technology, since the size of the heater structure itself is very small, on the order of hundreds of microns, refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com