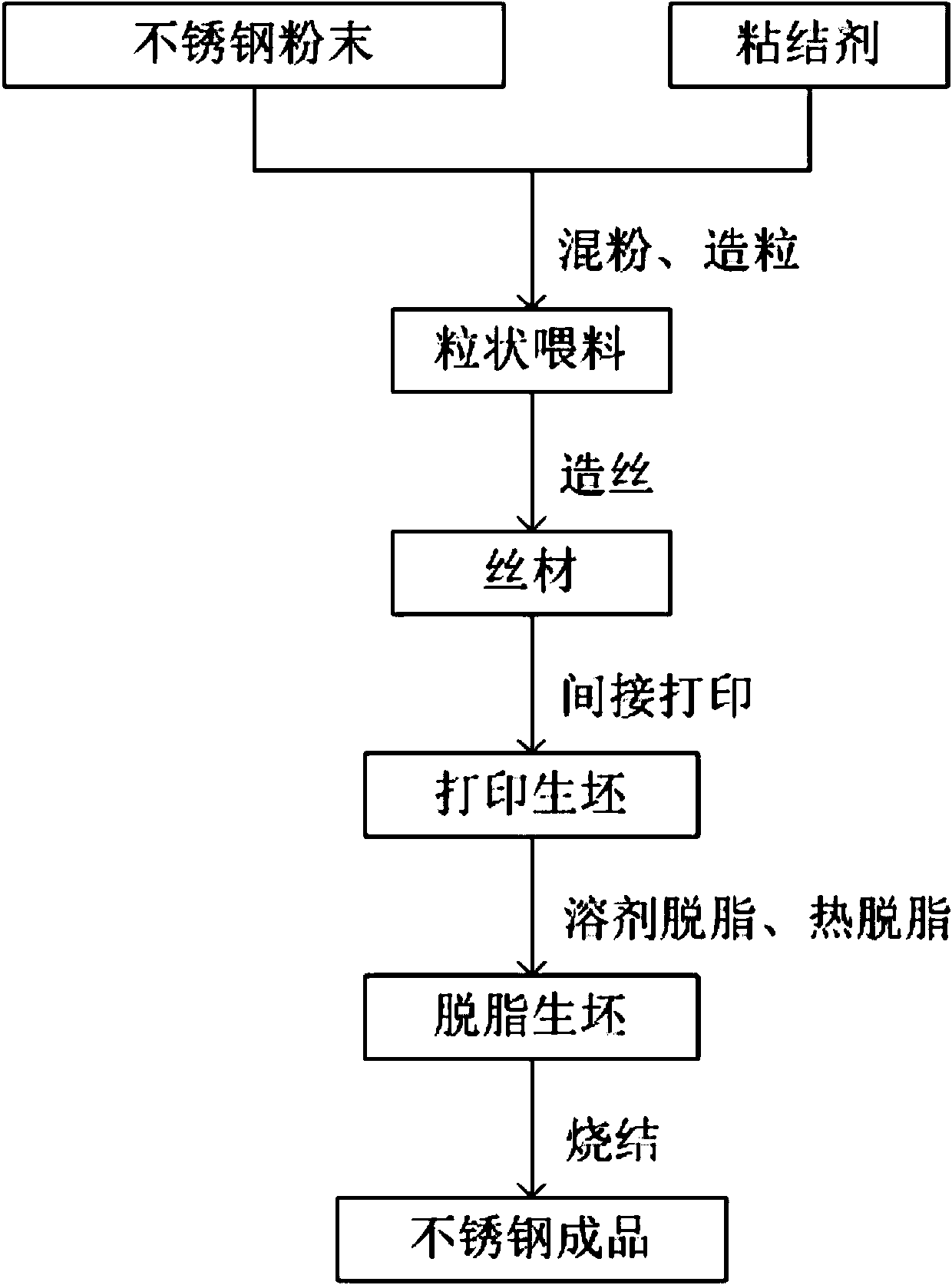

Low-cost stainless steel indirect additive manufacturing method

An additive manufacturing and stainless steel technology, applied in the field of additive manufacturing, can solve problems such as alloy phase transition and tissue evolution adverse reactions, high 3D printing equipment costs, etc., to achieve the effects of avoiding adverse reactions, high product yield, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Pour 90wt.% of 304 stainless steel powder and 10wt.% of binder into the mixing chamber of the kneader and mix and stir. The temperature of mixing and stirring is 160°C, and the time is 2h. The binder is made of the following raw materials in parts by weight Ingredients: 20 parts of microcrystalline wax, 60 parts of polyoxymethylene, 6 parts of polyethylene, 3.5 parts of paraffin wax, 0.2 part of stearic acid, 304 stainless steel powder particle diameter is 8~12µm; after the mixed powder is cooled, pass through a granulator or crushing machine to prepare granular feed, and then use injection molding machine or silk machine to process the granular feed into filaments containing binder and with a diameter of 1~5mm, and the temperature of the injection nozzle is 160°C; The filament material is loaded onto a conventional plastic 3D printer to print out a stainless steel green body. The temperature range of the printing nozzle of the plastic 3D printer is 160°C; The acid time...

Embodiment 2

[0028] Embodiment 2: Pour 92wt.% of 304 stainless steel powder and 8wt.% of binder into the mixing chamber in the kneader and mix and stir. The temperature of mixing and stirring is 180 ° C, and the time is 6h. The binder is composed of the following weight 2 parts of raw materials: 25 parts of microcrystalline wax, 70 parts of polyoxymethylene, 9 parts of polyethylene, 4.5 parts of paraffin wax, 1 part of stearic acid, 304 stainless steel powder particle diameter of 8~12µm; after the mixed powder is cooled, Prepare granular feed through a granulator or a crusher, and then use an injection molding machine or a silk machine to process the granular feed into filaments containing binders with a diameter of 1-5mm, and the temperature of the injection nozzle is 180°C; The filament containing the binder is loaded on a conventional plastic 3D printer to print out a stainless steel green body. The temperature range of the printing nozzle of the plastic 3D printer is 180°C; the stainles...

Embodiment 3

[0029] Embodiment 3: Pour 91wt.% of 304 stainless steel powder and 9wt.% of binder into the mixing chamber in the kneader and mix and stir. The temperature of mixing and stirring is 170 ° C, and the time is 4h. The binder consists of the following weight 2 parts of raw materials: 23 parts of microcrystalline wax, 65 parts of polyoxymethylene, 7 parts of polyethylene, 4 parts of paraffin wax, 0.6 part of stearic acid, 304 stainless steel powder particle diameter of 8~12μm; after the mixed powder is cooled, Prepare granular feed through a granulator or a crusher, and then use an injection molding machine or a silk machine to process the granular feed into filaments with a binder and a diameter of 1 to 5mm. The temperature of the injection nozzle is 170°C. The filament containing the binder is loaded on a conventional plastic 3D printer to print a stainless steel green body. The temperature range of the printing nozzle of the plastic 3D printer is 170°C; the stainless steel green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com