Polymer, organic film composition, and method for forming pattern

A technology of polymer and composition, applied in opto-mechanical equipment, photo-engraving process of pattern surface, photosensitive material for opto-mechanical equipment, etc. The effect of etching resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

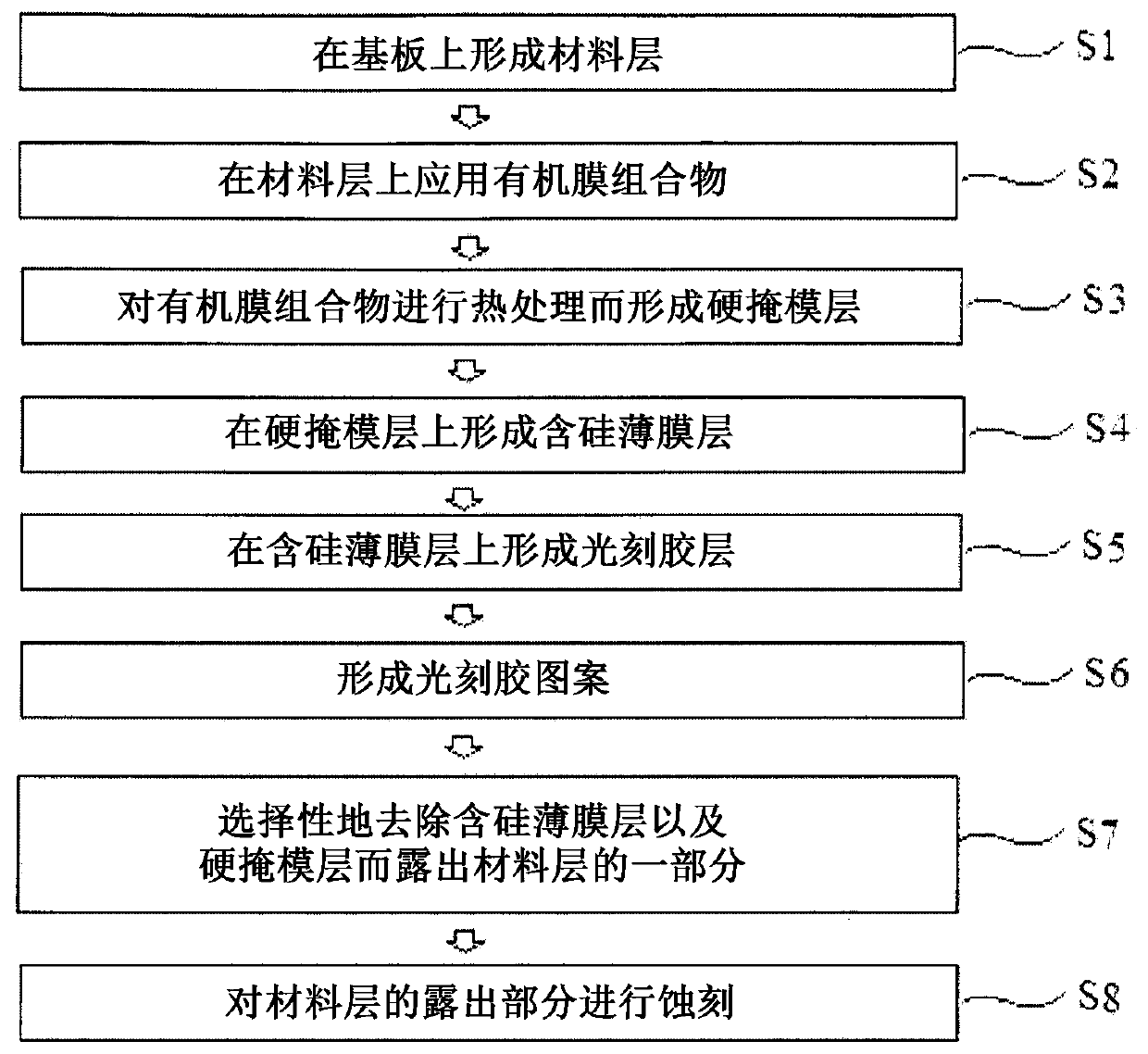

Method used

Image

Examples

Synthetic example 1

[0105] 28.4g (0.10mol) of 1,2,3,4-benzenetetramine tetrahydrochloride (1,2 ,3,4-benzonetetraminetetrahydrochloride), 40.6g (0.10mol) of 4,4'-(9H-fluorene-9-ylidene)bisbenzoic acid (4,4'-(9H-fluorene-9-ylidene)bisbenzoic acid ) and 300 g of polyphosphoric acid (polyphosphoric acid), and then stirred at 150° C. for 24 hours to 48 hours to perform a polymerization reaction. The reaction was completed at a weight average molecular weight of 1,000 to 5,000. After the polymerization reaction was completed, the reactant was slowly cooled at normal temperature, and then the above reactant was neutralized with a 1M NaOH solution, and the resulting solid was filtered. After washing with distilled water, ethanol and diethyl ether in sequence, the compound represented by Chemical Formula 2-1 (MW: 2100) was obtained after drying.

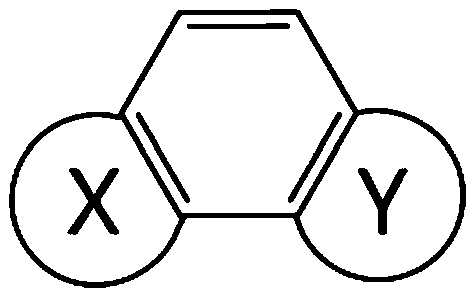

[0106] [chemical formula 2-1]

[0107]

Synthetic example 2

[0109] 21.3g (0.10mol) of 2,4-diamino-1,3-benzenedithiol dihydrochloride (2,4-diamino-1,3-benzenediol dihydrochloride ), 40.6g (0.10mol) of 4,4'-(9H-fluorene-9-ylidene)bisbenzoic acid (4,4'-(9H-fluorene-9-ylidene)bisbenzoic acid) and polyphosphoric acid (polyphosphoric acid) 300 g, after that, the polymer (MW: 2300) represented by Chemical Formula 2-2 was obtained through the same synthesis process as in Synthesis Example 1.

[0110] [chemical formula 2-2]

[0111]

Synthetic example 3

[0113] 24.5g (0.10mol) of 2,4-diamino-1,3-benzenedithiol dihydrochloride (2,4-diamino-1,3-benzenedithiol dihydrochloride ), 40.6g (0.10mol) of 4,4'-(9H-fluorene-9-ylidene)bisbenzoic acid (4,4'-(9H-fluorene-9-ylidene)bisbenzoic acid) and 300g of polyphosphoric acid (polyphosphoric acid), and then through the same synthesis process as in Synthesis Example 1, the polymer (MW: 2000) represented by Chemical Formula 2-3 was obtained.

[0114] [chemical formula 2-3]

[0115]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com