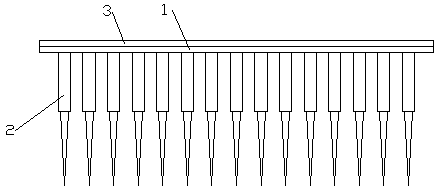

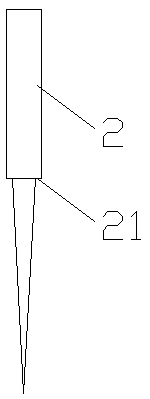

Soft-back microneedle and manufacturing method thereof

A production method and microneedle technology, which is applied in the direction of microneedles, needles, and other medical devices, can solve the problems that povidone microneedles are difficult to insert into the skin, cannot be curved, matched, and the hardness of the microneedle substrate is large, achieving Does not cause skin allergies, good skin feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

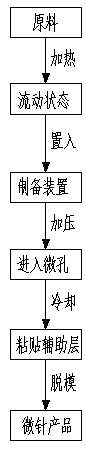

[0041] The production process of the soft back microneedle in this embodiment is as follows: image 3 As shown, the manufacturing method of the soft-backed microneedle in this embodiment includes the following steps: (1) heating and deforming the thermoplastic raw material for preparing the microneedle to a fluid state; (2) as Figure 6 As shown, the bottom plate 8, the soft liner 7, the isolation layer 6, the template 5 and the upper plate 4 for preparing the microneedles are placed in sequence from bottom to top, and the upper plate 4, the template 5, the isolation layer 6, the soft liner 7 and base plate 8 are all heat-resistant materials, and the isolation layer 6 is an air-permeable and liquid-tight material. The template 5 is provided with a microporous area 51 corresponding to the needles of the microneedles. There are several microporous areas in one microporous area. A microhole, the microhole is a through hole provided on the template, and the position corresponding ...

Embodiment 2

[0043] The production process of the soft back microneedle in this embodiment is as follows: Figure 4 As shown, the manufacturing method of the soft-backed microneedle in this embodiment includes the following steps: (1) process the thermoplastic raw material for preparing the microneedle into powder, and weigh the powder raw material equal to the weight of a single microneedle; (2) as Figure 6 as shown in Figure 6 As shown, the bottom plate 8, the soft liner 7, the isolation layer 6, the template 5 and the upper plate 4 for preparing the microneedles are placed in sequence from bottom to top, and the upper plate 4, the template 5, the isolation layer 6, the soft liner 7 and base plate 8 are all heat-resistant materials, and the isolation layer 6 is an air-permeable and liquid-tight material. The template 5 is provided with a microporous area 51 corresponding to the needles of the microneedles. There are several microporous areas in one microporous area. A microhole, the m...

Embodiment 3

[0045] The production process of the soft back microneedle in this embodiment is as follows: Figure 5 As shown, the manufacturing method of the soft-backed microneedle in this embodiment includes the following steps: (1) processing the thermoplastic raw material for preparing the microneedle into a solid with the same weight as a single microneedle; (2) as Figure 6 as shown in Figure 6 As shown, the bottom plate 8, the soft liner 7, the isolation layer 6, the template 5 and the upper plate 4 for preparing the microneedles are placed in sequence from bottom to top, and the upper plate 4, the template 5, the isolation layer 6, the soft liner 7 and base plate 8 are all heat-resistant materials, and the isolation layer 6 is an air-permeable and liquid-tight material. The template 5 is provided with a microporous area 51 corresponding to the needles of the microneedles. There are several microporous areas in one microporous area. A microhole, the microhole is a through hole pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com