Lanthanum-doped magnesium ferrite composite material and preparation method and application thereof

A technology of magnesium ferrite and composite materials, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve problems such as uneconomical, long-lasting adsorption capacity, and slow adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

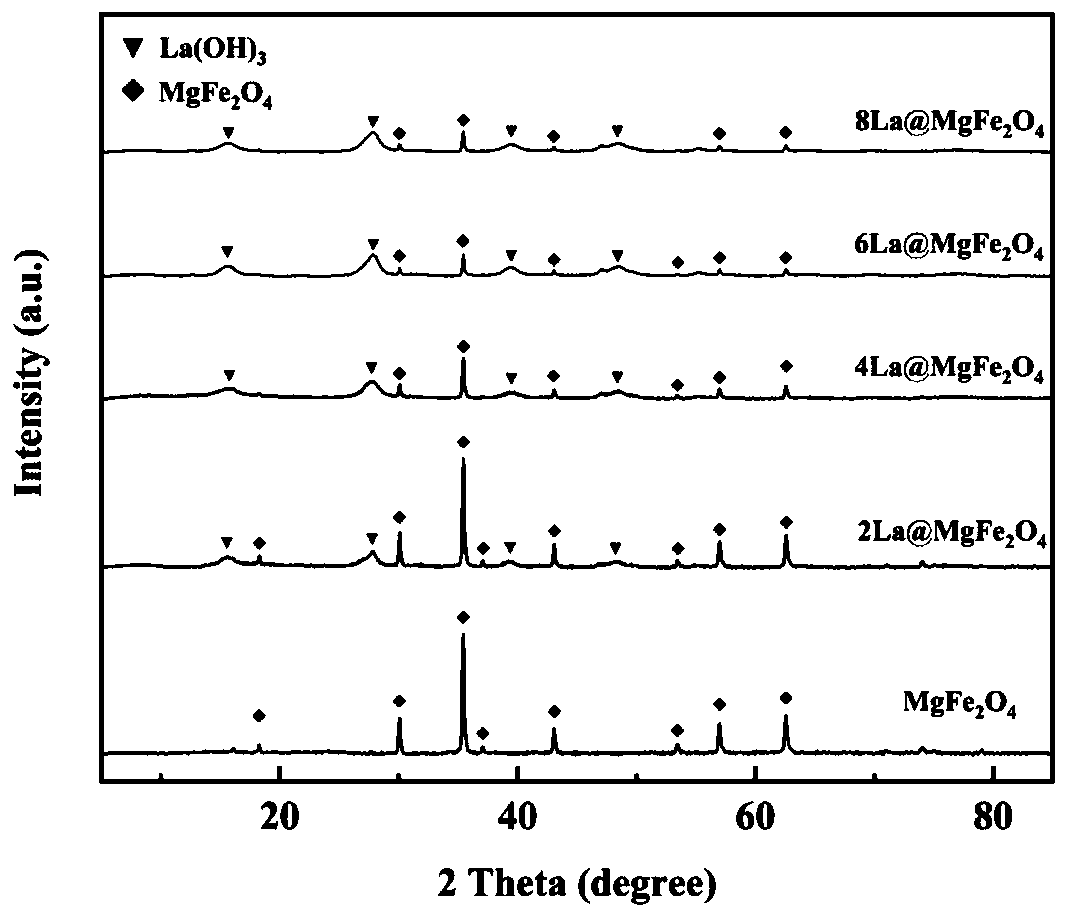

[0040] Example Preparation of Lanthanum-doped Magnesium Ferrite Composite Material

[0041] 1. Reagents

[0042] Magnesium Chloride (MgCl 2 ·6H 2 O), ferric oxide (Fe 3 o 4 ), lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), potassium dihydrogen phosphate (KH 2 PO 4 ), hydrochloric acid (HCl), sodium hydroxide (NaOH). Potassium dihydrogen phosphate (KH 2 PO 4 ) to prepare a standard phosphoric acid solution. All chemical reagents were of analytical grade.

[0043] 2. Preparation method

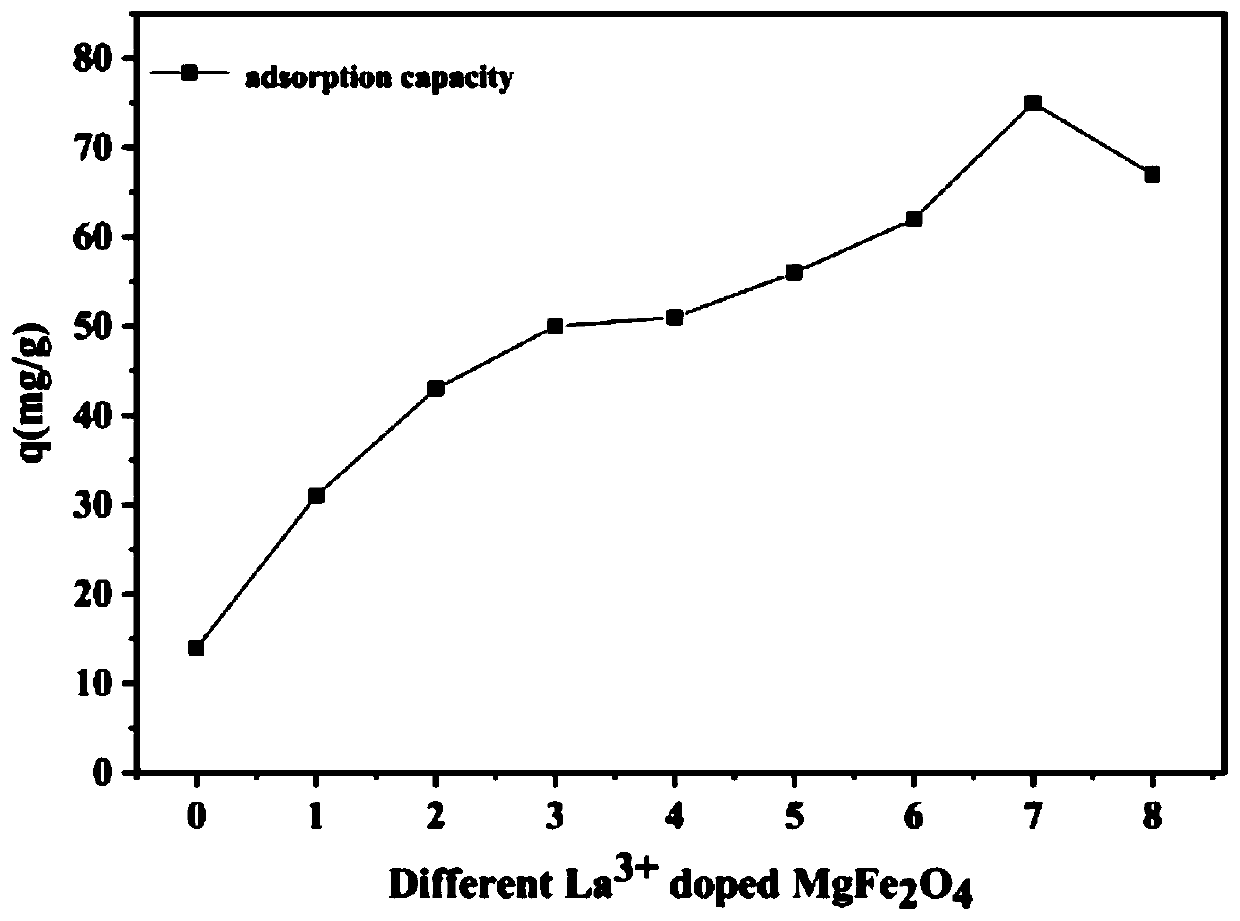

[0044] 10mmol Fe 3 o 4 , 5mmol MgCl 2 ·6H 2 O and x mmol of La(NO 3 ) 3 ·6H 2 O (x=0, 10, 20, 30, 40, 50, 60, 70, 80) was mixed in 100ml of water and stirred vigorously, wherein, Fe 3 o 4 and Mg 2+ The molar ratio is 2, adjust the amount of lanthanum nitrate, so that La(NO 3 ) 3 ·6H 2 O and Mg 2+ The molar ratio is from 0:1, 1:1, 2:1, 3:1... to 8:1.

[0045] The mixture was then sonicated at 300w for 30 minutes. Then, add 30ml NaOH solution and stir (NaOH and La(NO 3 ) 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com