Graphite-like carbon nitride-based photocatalytic composite material as well as preparation method and application thereof

A composite material and carbon nitride technology, applied in the field of photocatalytic materials, can solve the problems of limited photocatalytic efficiency and limited absorption of visible light with low surface area, and achieve high photocatalytic efficiency, good photocatalytic efficiency and reduced recombination rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

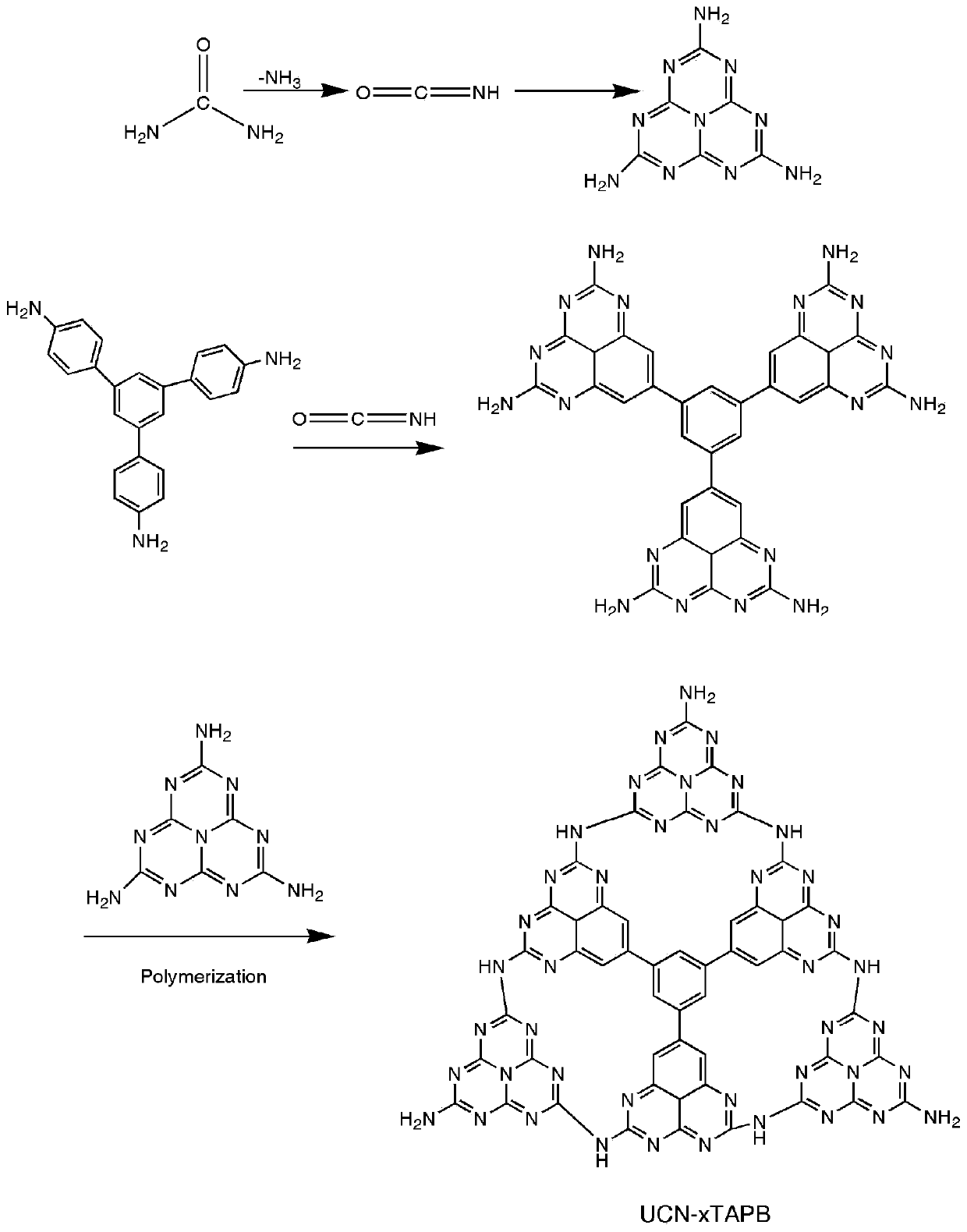

[0036] a g-C 3 N 4 The preparation method of base photocatalytic composite material comprises the following steps:

[0037] (1) Under normal temperature conditions, weigh 20 g of urea and 2 mg of TAPB in a grinding bowl, grind the raw materials until the powdery particles are mixed uniformly, and obtain a mixture of the two;

[0038](2) The mixture is placed in a 100ml alumina crucible with a cover, and then the crucible is placed in a muffle furnace, and the temperature is gradually raised to 550°C at a heating rate of 10°C / min, and then heated at a constant temperature of 550°C for 4h;

[0039] (3) Naturally cool to room temperature, and grind the obtained sample sufficiently again.

[0040] A kind of g-C is prepared by the above steps 3 N 4 Based photocatalytic composite material, the sample is named UCN-2TAPB.

Embodiment 2

[0042] a g-C 3 N 4 The preparation method of base photocatalytic composite material comprises the following steps:

[0043] (1) Under normal temperature conditions, weigh 20 g of urea and 4 mg of TAPB in a grinding bowl, grind the raw materials until the powdery particles are mixed uniformly, and obtain a mixture of the two;

[0044] (2) The mixture is placed in a 100ml alumina crucible with a cover, and then the crucible is placed in a muffle furnace, and the temperature is gradually raised to 550°C at a heating rate of 10°C / min, and then heated at a constant temperature of 550°C for 4h;

[0045] (3) Naturally cool to room temperature, and grind the obtained sample sufficiently again.

[0046] Compared with Example 1, the only difference is that the amount of TAPB added is 4 mg, and the prepared sample is named UCN-4TAPB.

Embodiment 3

[0048] a g-C 3 N 4 The preparation method of base photocatalytic composite material comprises the following steps:

[0049] (1) Under normal temperature conditions, weigh 20 g of urea and 6 mg of TAPB in a grinding bowl, grind the raw materials until the powdery particles are mixed uniformly, and obtain a mixture of the two;

[0050] (2) The mixture is placed in a 100ml alumina crucible with a cover, and then the crucible is placed in a muffle furnace, and the temperature is gradually raised to 550°C at a heating rate of 10°C / min, and then heated at a constant temperature of 550°C for 4h;

[0051] (3) Naturally cool to room temperature, and grind the obtained sample sufficiently again.

[0052] Compared with Example 1, the only difference is that the amount of TAPB added is 6 mg, and the prepared sample is named UCN-6TAPB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com