Process method for preparing sulfuric acid from low-sulfur-content pyrite

A process method, pyrite technology, applied in the field of sulfuric acid preparation, can solve the problems affecting the purity of sulfuric acid, reduce the rate of sulfur dioxide generation, increase the reaction time, etc., and achieve the effect of shortening the heating time, improving the purity and increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

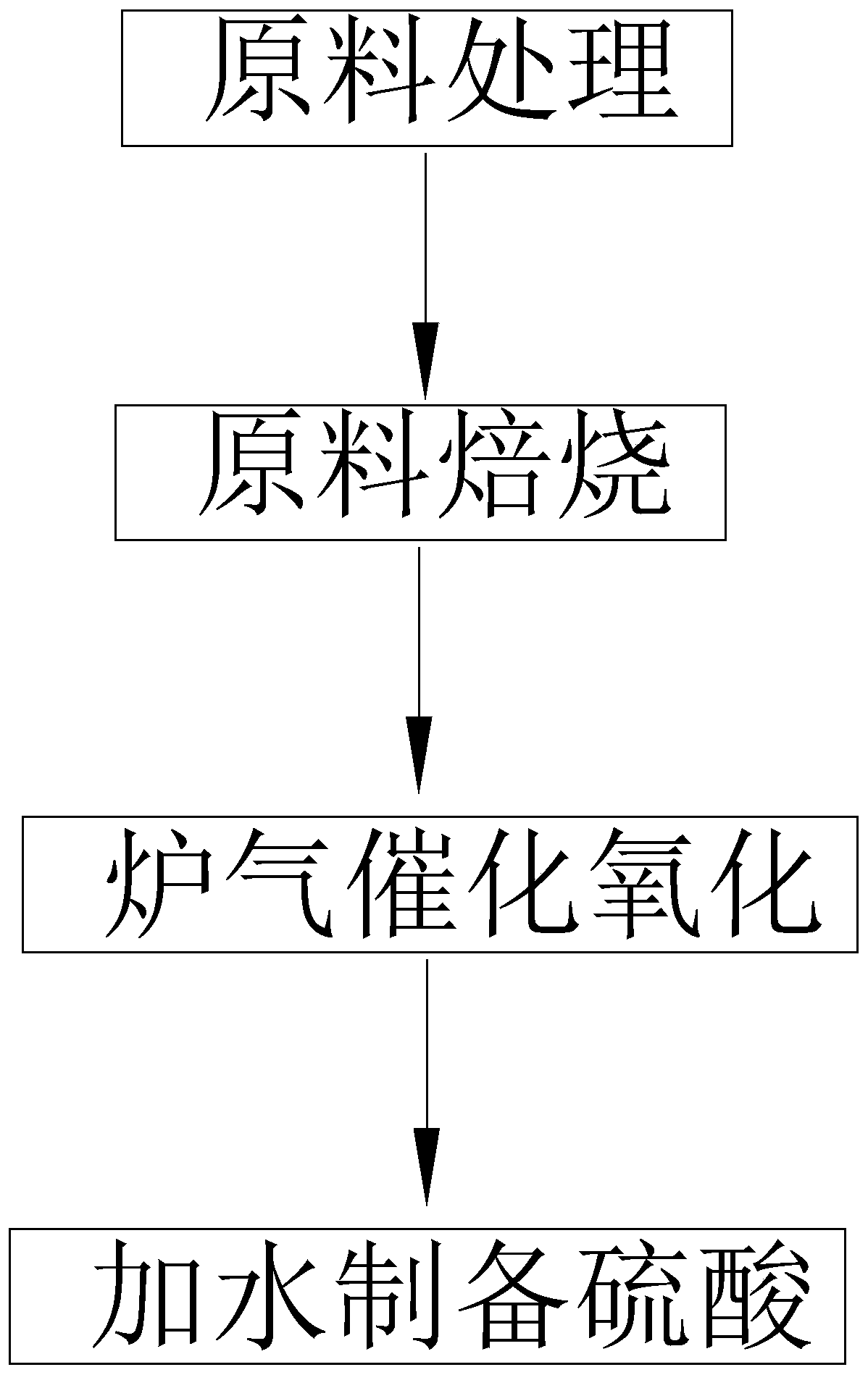

[0032] refer to figure 1 , is a kind of process method that utilizes pyrite of low sulfur content to prepare sulfuric acid disclosed by the present invention, comprises the steps:

[0033] A1. Raw material processing: pulverizing pyrite ore;

[0034] A2. Raw material roasting: import the powdered pyrite raw material into the roasting furnace for high-temperature roasting, and the roasting temperature is 800°C;

[0035] A3. Catalytic oxidation of furnace gas: using a catalyst to mix the sulfur dioxide discharged from the roasting furnace with oxygen to oxidize sulfur dioxide into sulfur trioxide;

[0036] A4. Add water to prepare sulfuric acid: mix sulfur trioxide with water to make sulfuric acid.

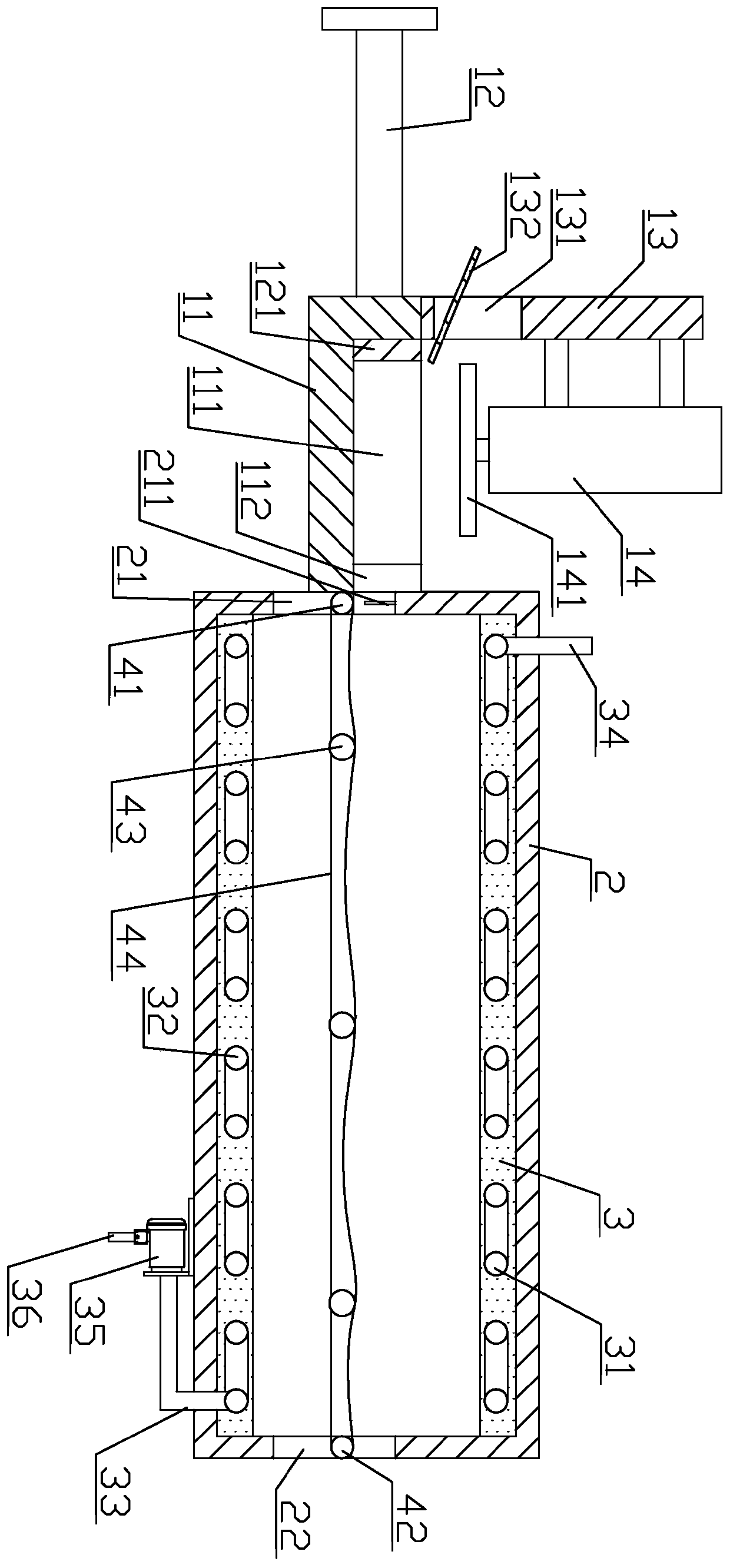

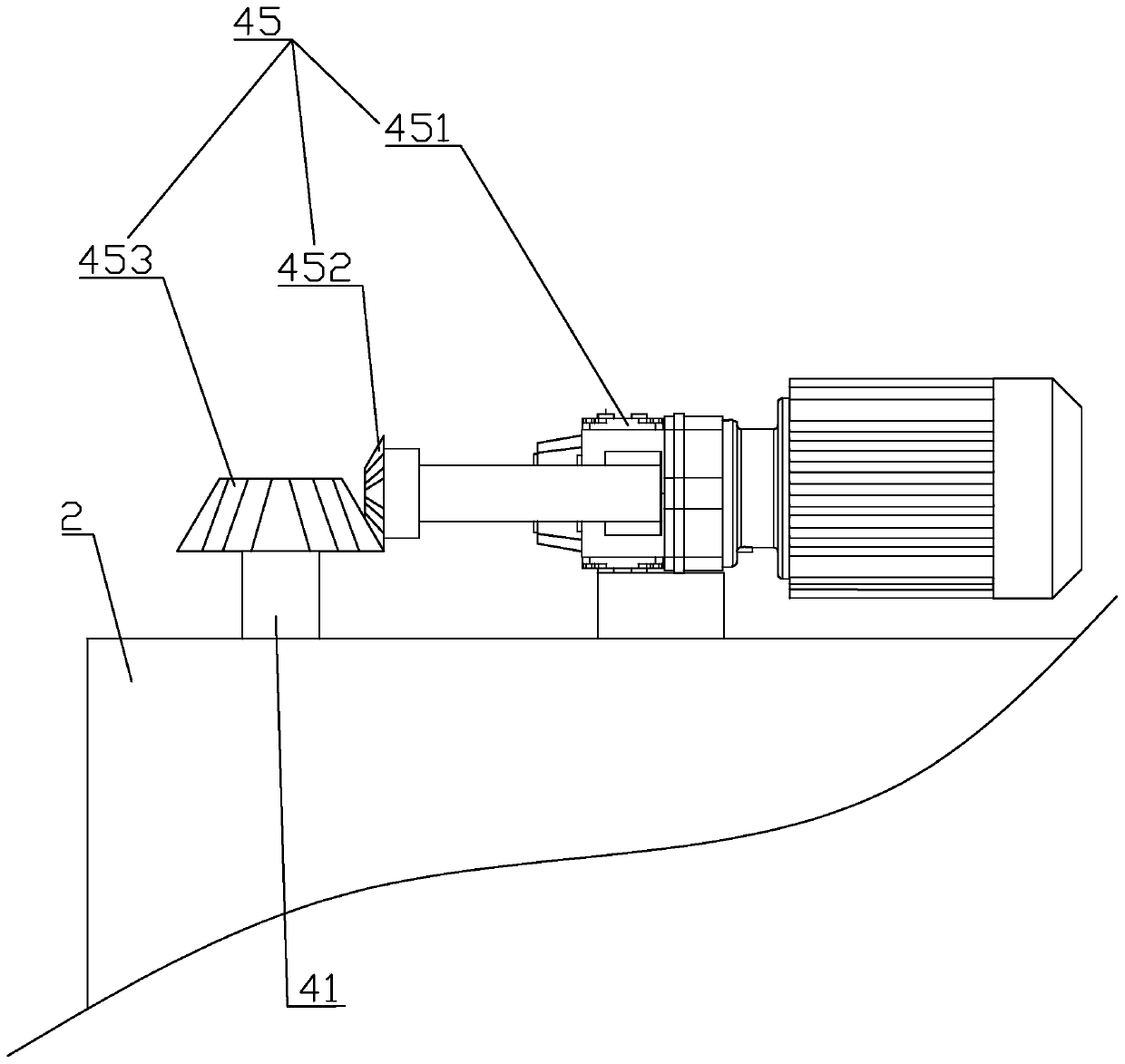

[0037] refer to figure 2 , The roasting furnace used in the above steps A1 and A2 includes a roasting furnace body, a pulverizer and a preheating device. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com