Method for blending commercial concrete into 3D printing concrete on site

A commercial concrete and 3D printing technology, which is applied in the fields of manufacturing tools, sustainable waste treatment, solid waste management, etc., to achieve the effect of simple preparation process and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

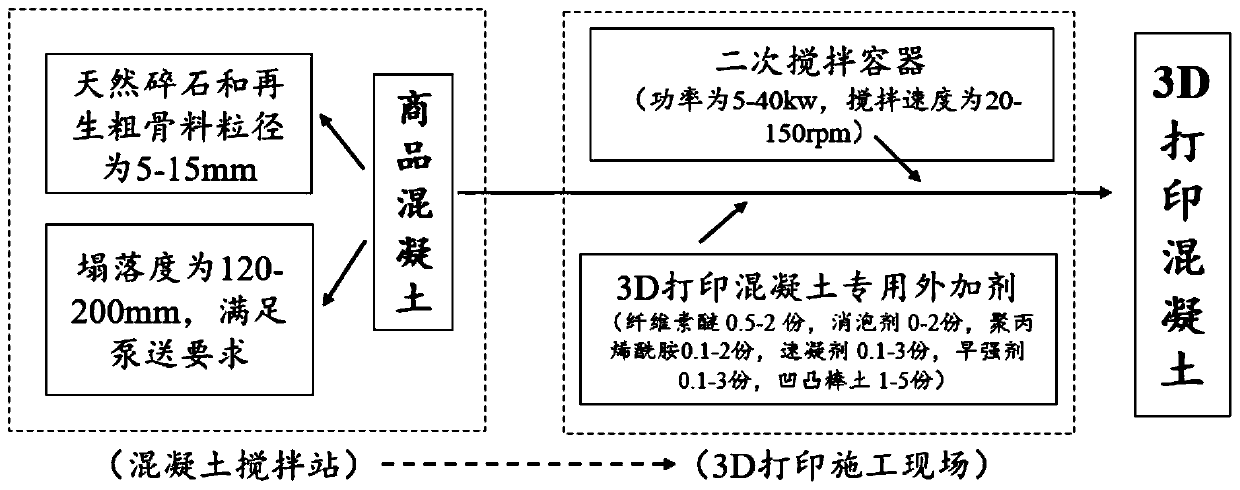

Method used

Image

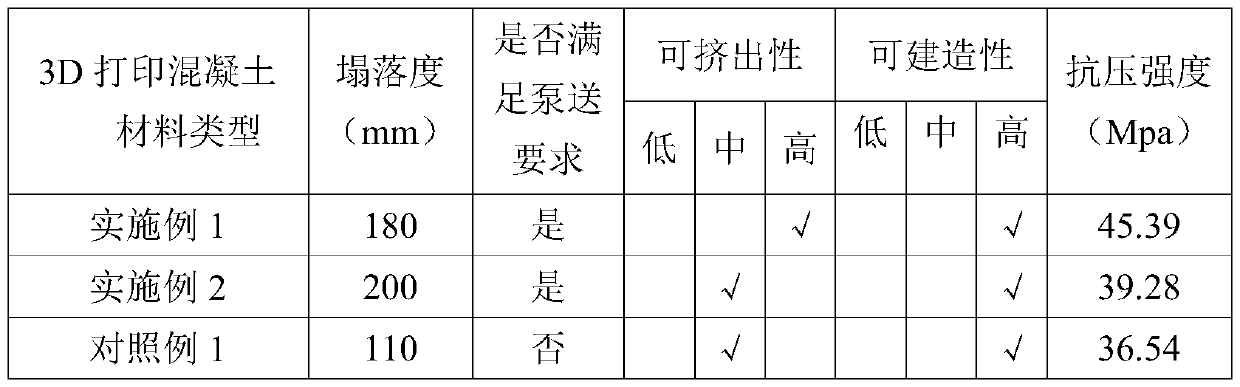

Examples

Embodiment 1

[0059] A method for preparing 3D printed concrete by deploying commercial concrete on site, comprising the following steps:

[0060] Step 1, preparing commercial concrete, said commercial concrete, in parts by weight, includes the following components: 120 parts of gravel, 150 parts of river sand, 23.6 parts of recycled coarse aggregate, 99 parts of cement, 17.8 parts of active admixture, 0.5 parts of fiber, 0.36 parts of water reducer and 40 parts of water.

[0061] Among them, the particle size of natural crushed stone is 5-15mm, the particle size of river sand is 0.15-4.75mm, and the fineness modulus is 2.2. The recycled coarse aggregate is broken into particles with a particle size of 5-15mm from construction waste. 3%-8%, the cement is P.O 42.5 ordinary Portland cement, the active admixture is silica fume, the fiber is polyethylene fiber, including 5-20mm and other lengths, and the water reducer is polycarboxylate water reducer , the water is tap water.

[0062] Step 2:...

Embodiment 2

[0068] A method for preparing 3D printed concrete by deploying commercial concrete on site, comprising the following steps:

[0069] Step 1, preparing commercial concrete, said commercial concrete, in parts by weight, includes the following components: 100 parts of gravel, 108 parts of river sand, 27.5 parts of recycled coarse aggregate, 64.5 parts of cement, 27.75 parts of active admixture, 0.8 parts of fiber, 0.55 parts of water reducer and 32.3 parts of water.

[0070] Among them, the particle size of crushed stone is 5-15mm, the particle size of river sand is 0.15-4.75mm, and the fineness modulus is 1.8. The recycled coarse aggregate is broken into particles with a particle size of 5-15mm from construction waste. The water absorption rate of the material is 3%-8%, the cement is P.O42.5 ordinary Portland cement, the active admixture is fly ash, the fiber is polyethylene fiber, the length is 6mm, and the water reducer is polycarboxylic acid Water reducing agent, water is ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com