Self-repairing high-durability concrete with impact wear resistance and preparation method thereof

A concrete and self-repairing technology, which is applied in the field of concrete, can solve problems such as failure to achieve the best use state, high water content of tuff raw ore, and ineffective use of stone powder, so as to achieve the effects of improving durability, improving durability, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

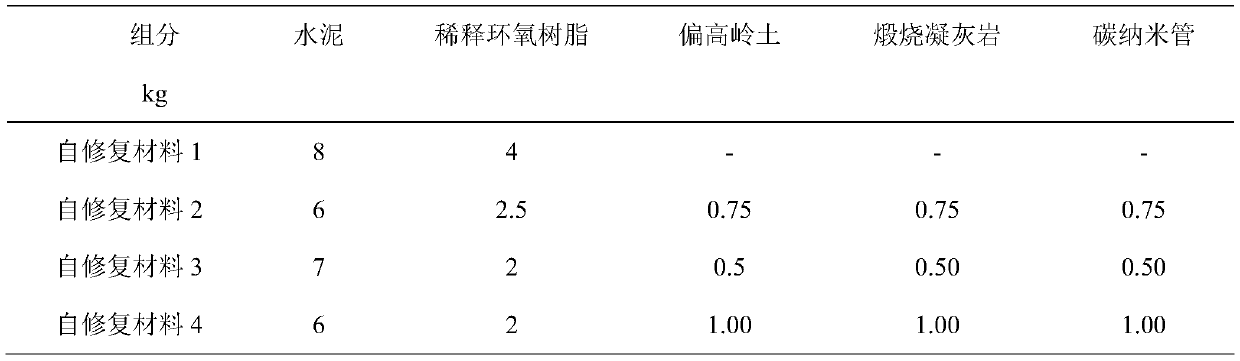

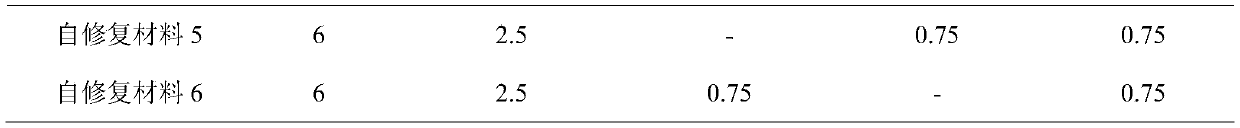

Examples

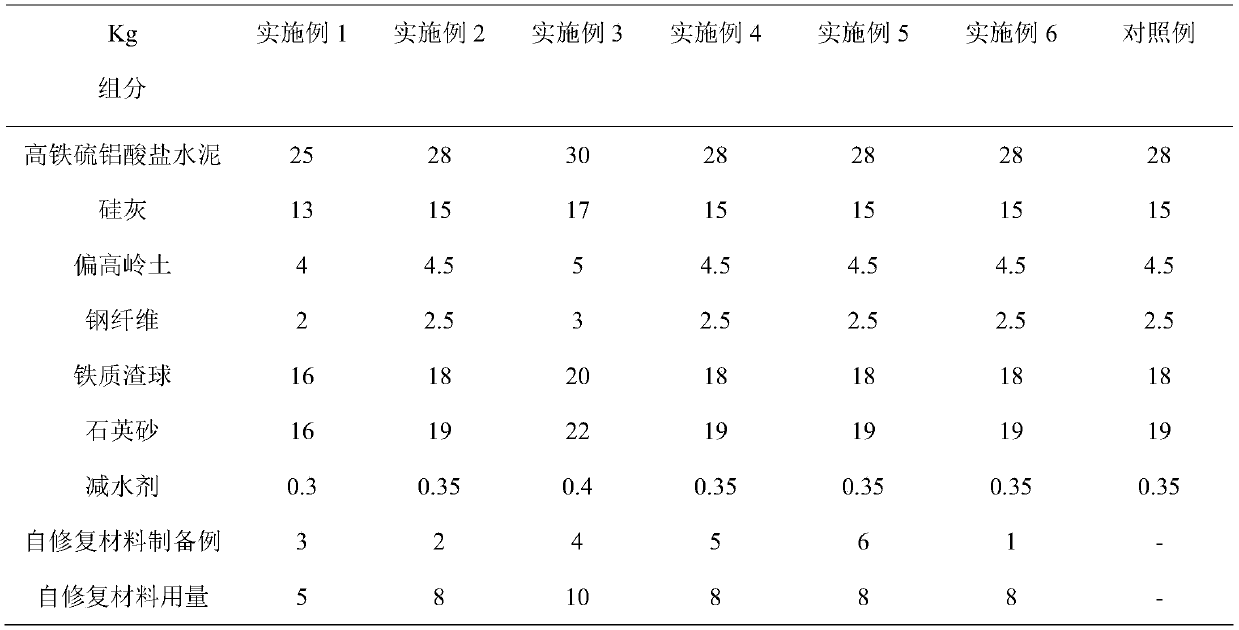

Embodiment 1

[0049] S1: Grinding and ball milling the kaolin after crushing. The grinding time is 1.5h, the grinding speed is 125r / min, the steel ball gradation used in the ball mill is: the number ratio of Ф20 steel balls, Ф10 steel balls and Ф6 Fu steel balls is 1:6:25, the steel balls and The mass ratio of kaolin is 5:1, and then sieved with a 70μm square hole sieve to make the specific surface area reach 20000cm 2 / g or more, and finally calcined in a high-temperature furnace for 1.5 hours to obtain metakaolin. The content of iron oxide in high iron sulfoaluminate cement is 9%; the fineness modulus of iron slag ball is 2.7; the fineness modulus of quartz sand is 2.7; agent.

[0050] S2: According to the ratio of raw materials in Table 2, the high-iron sulfoaluminate cement, silica fume, metakaolin, steel fiber, iron slag balls, and quartz sand in S1 were fully mixed and evenly prepared to prepare premix A;

[0051] S3: According to the ratio of raw materials in Table 2, add aliphati...

Embodiment 2

[0053] S1: Grinding and ball milling the kaolin after crushing. The grinding time is 1h, the grinding speed is 100r / min, the steel ball gradation used in the ball mill is: the number ratio of Ф20 steel balls, Ф10 steel balls and Ф6 Fu steel balls is 1:6:25, the steel balls and kaolin The mass ratio is 7:1, and then sieved with a 50μm square hole sieve to make the specific surface area reach 20000cm 2 / g or more, and finally calcined in a high-temperature furnace for 1 hour to obtain metakaolin. The content of iron oxide in high iron sulfoaluminate cement is 12%; the fineness modulus of iron slag balls is 2.9; the fineness modulus of quartz sand is 2.9; the water reducer is polycarboxylate high-efficiency water reducer.

[0054] S2: According to the ratio of raw materials in Table 2, the high-iron sulfoaluminate cement, silica fume, metakaolin, steel fiber, iron slag balls, and quartz sand in S1 were fully mixed and evenly prepared to prepare premix A;

[0055] S3: According ...

Embodiment 3

[0057] S1: Grinding and ball milling the kaolin after crushing. The grinding time is 2 hours, the grinding speed is 150r / min, the steel ball gradation used in the ball mill is: the number ratio of Ф20 steel balls, Ф10 steel balls and Ф6 Fu steel balls is 1:6:25, the steel balls and kaolin The mass ratio is 8:1, and then sieved with an 80μm square hole sieve to make the specific surface area reach 20000cm 2 / g or more, and finally calcined in a high-temperature furnace for 2 hours to obtain metakaolin. The content of iron oxide in high-iron sulfoaluminate cement is 15%; the fineness modulus of iron slag balls is 3.0; the fineness modulus of quartz sand is 3.0; the superplasticizer is naphthalenesulfonate superplasticizer.

[0058] S2: According to the ratio of raw materials in Table 2, the high-iron sulfoaluminate cement, silica fume, metakaolin, steel fiber, iron slag balls, and quartz sand in S1 were fully mixed and evenly prepared to prepare premix A;

[0059] S3: Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com