Low-hardness high-tear-resistance self-lubricating addition type liquid silicone rubber, preparation method and application thereof

A technology of silicone rubber and silicone rubber composition, applied in the field of silicone rubber, can solve the problems of high hardness, inability to meet the requirements of cyclic plugging and use of automobile plug-in parts, damage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

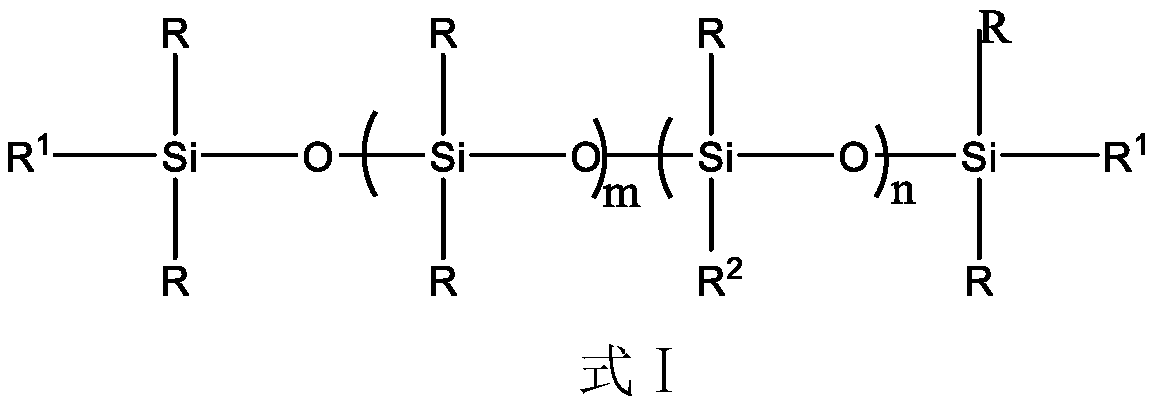

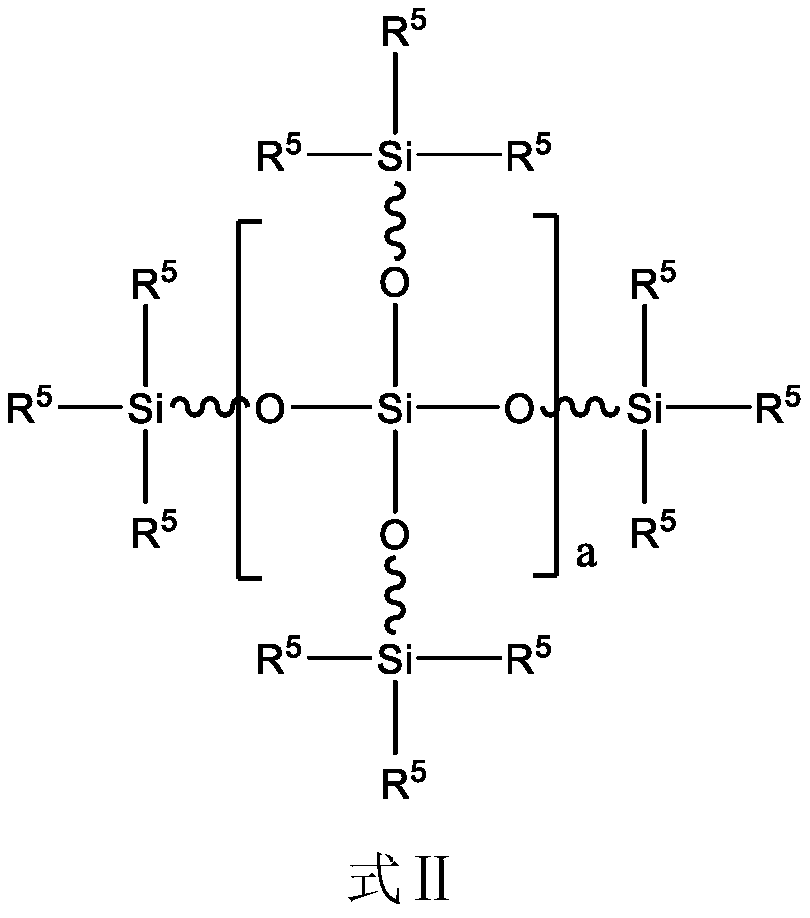

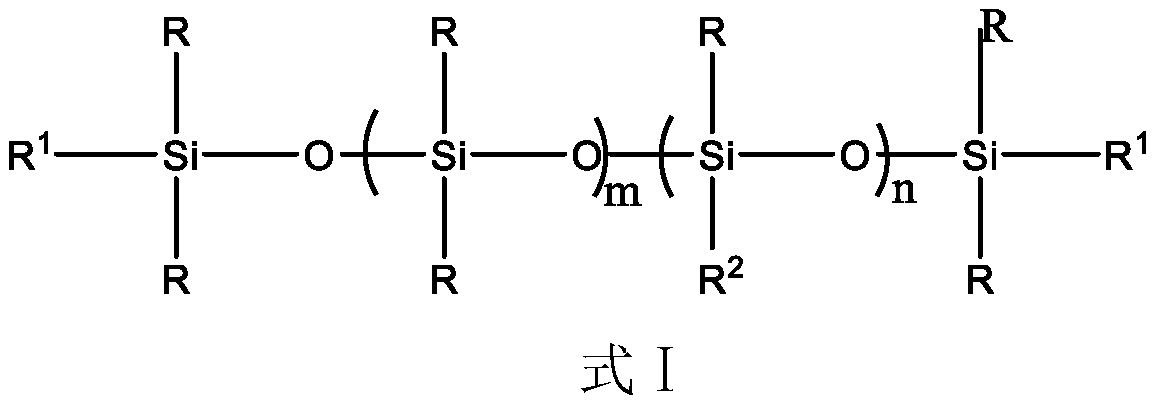

Method used

Image

Examples

preparation example 1

[0078] In a kneader or a planetary mixer, 37 parts by weight of vinyl-terminated polysiloxane with a viscosity of 100,000 mPa·s and an alkenyl content of 0.026 mmol / g, and 7.8 parts of vinyl polysiloxane with a viscosity of 60,000 mPa·s and an alkenyl content of 0.030 The vinyl-terminated polysiloxane of mmol / g, the specific surface area of 25 parts BET is 300m 2 / g of fumed silica and 7.05 parts of hexamethyldisilazane, 0.15 parts of tetramethyldivinylsilazane and 6.5 parts of deionized water were fully mixed under the protection of an inert atmosphere at 80°C for 1 ~ 2 hours, then heat up to 130 ~ 150 ° C and start vacuuming for 2 ~ 4 hours, keep the temperature at 150 ~ 170 ° C during vacuuming, then cool down to 110 ~ 140 ° C, add 16.5 parts of viscosity 20000mPa·s alkenyl content is 0.035mmol / g vinyl-terminated polysiloxane, and stir evenly to obtain liquid silicone rubber base rubber 1.

preparation example 2

[0080] In a kneader or a planetary mixer, 40 parts by weight of vinyl-terminated polysiloxane with a viscosity of 60,000mPa·s and an alkenyl content of 0.030mmol / g, and 2.5 parts of vinyl polysiloxane with a viscosity of 200,000mPa·s and an alkenyl content of 0.035 The specific surface area of mmol / g of vinyl-terminated polysiloxane and 27.5 parts of BET is 400m 2 / g of fumed silica and 8 parts of hexamethyldisilazane, 0.5 parts of tetramethyldivinylsilazane and 4.5 parts of deionized water were fully mixed under the protection of an inert atmosphere at 80°C for 1 ~ 2 hours, then heat up to 130 ~ 150 ° C and start vacuuming for 2 ~ 4 hours, keep the temperature at 150 ~ 170 ° C during vacuuming, then cool down to 110 ~ 140 ° C, add 17 parts of viscosity 60000mPa·s alkenyl content is 0.030mmol / g vinyl-terminated polysiloxane, stirred evenly to obtain liquid silicone rubber base rubber 2.

[0081] Example Preparation of liquid silicone rubber

Embodiment 1

[0083] Preparation and vulcanization of component AB: 85 parts of the above base rubber 1, 4.5 parts of vinyl-terminated polysiloxane with a viscosity of 3500mPa·s and an alkenyl content of 0.08mmol / g, 4 parts of a vinyl-terminated polysiloxane with a viscosity of 1000mPa·s, Side chain vinyl polysiloxane with a group content of 0.12mmol / g, 0.5 parts of vinyl polysiloxane with a viscosity of 400mPa·s and an alkenyl content of 0.9mmol / g in both terminal and side chains, 0.012 parts of cal Stir-type platinum catalyst, 6 parts of methylphenylpolysiloxane with a viscosity of 120mPa s and a refractive index of 1.49, stirred and dispersed in a planetary mixer for 30-40min, mixed evenly and then vacuumed and defoamed to obtain a self-lubricating low-pressure variable liquid Silicone rubber component A.

[0084] 85 parts of the above-mentioned gum base 1, 1.5 parts of vinyl-terminated polysiloxane with a viscosity of 3500 mPa·s and an alkenyl content of 0.08 mmol / g, and 4 parts of a vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com