Shape memory plugging agent as well as preparation method and application thereof

A plugging agent and memory technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low organic high elastic polymer foam structure support force, slow speed, poor plugging effect, etc., to achieve Better leakage prevention and/or plugging effect, uniform distribution and strong support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

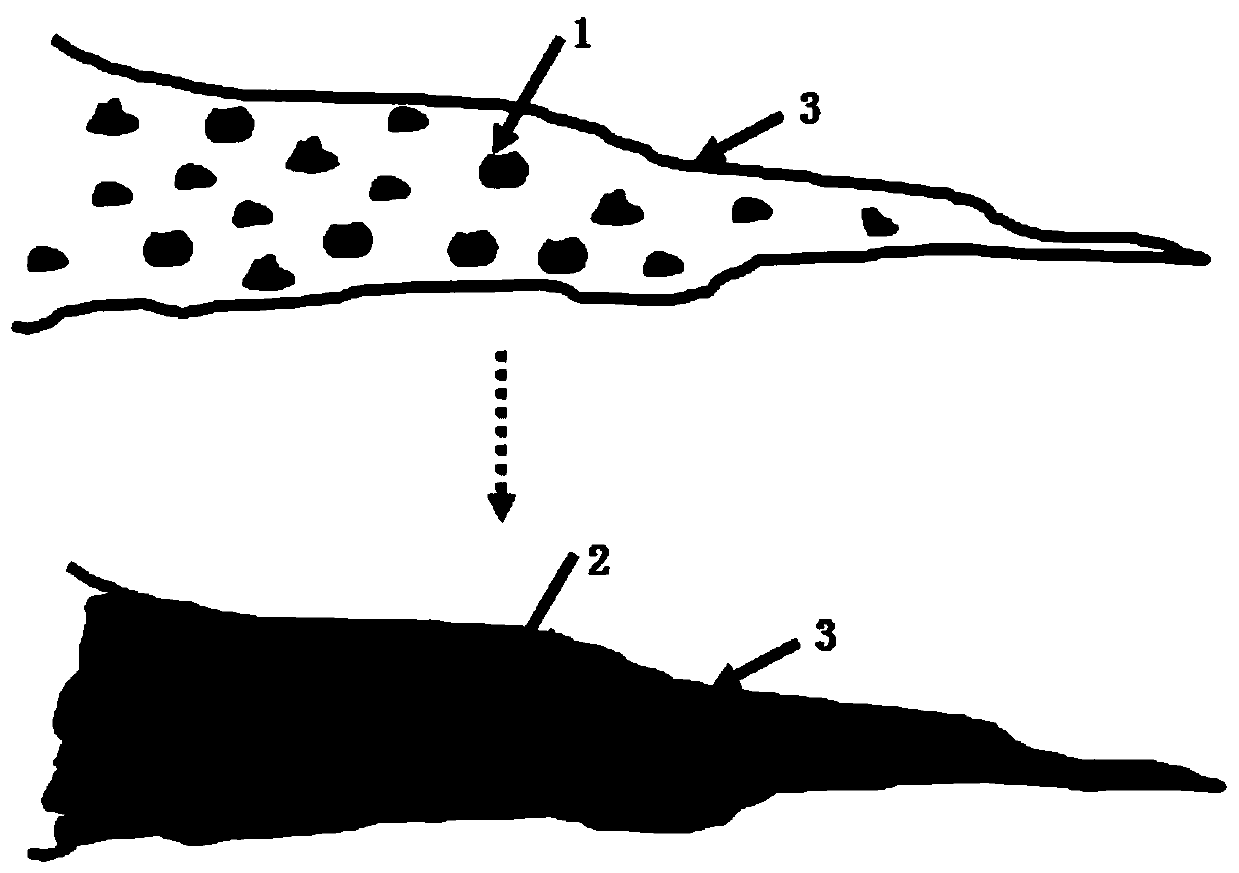

[0035] Another embodiment of the present invention also provides a method for preparing the above-mentioned shape memory plugging agent, which includes: pressing shape memory polymer particles or shape memory composite particles with a foam structure into a plate, cooling to room temperature, and cutting Shape memory plugging agent is obtained after granulation.

[0036] Preferably, in a preparation method of the above-mentioned shape memory plugging agent, granulation is performed at a temperature higher than or equal to the minimum value of the deformation temperature of the shape memory polymer particles or the shape memory composite particles to form a granular shape, which is convenient Mixed, and not easy to reunite. It should be pointed out that, generally speaking, the deformation temperature of temperature-sensitive shape memory polymers generally has a certain temperature range. Therefore, the two endpoints in the deformation temperature range are the lowest value of th...

Embodiment 1

[0044] This embodiment provides a shape memory polymer particle based on epoxy resin, including epoxy resin, curing agent, and accelerator. The epoxy resin is a low molecular weight epoxy resin, and the average value of n is less than 2. The softening point is lower than 50℃, the epoxy value is larger; the curing agent is selected from amine curing agent, and the ratio of curing agent and epoxy resin is adjusted to make the degree of crosslinking 60%-70%, Tg can be 50% It can be adjusted between ℃-100℃. Based on the above method, an epoxy resin shape memory polymer with a shape memory deformation temperature of 65-70℃ can be obtained. After foaming, an epoxy resin shape memory polymer with a foam structure can be prepared. Compress at 65-85°C to form a sheet, and cool down to room temperature.

[0045] The shape memory epoxy resin board was cut into a rectangular parallelepiped shape of 250mm×25mm×2.5mm for tensile testing. The shape memory epoxy resin board was cut into a recta...

Embodiment 2

[0048] This embodiment provides a shape memory polymer particle based on epoxy resin, including epoxy resin and curing agent, wherein the epoxy resin is an epoxy resin with a medium molecular weight, and the value is between 2 and 5, softening The point is between 50~95℃; the curing agent is selected from amine curing agent, and the ratio of curing agent to epoxy resin is adjusted so that the crosslinking degree is 90%-100%, and the curing process can be combined to make it The curing speed and curing temperature increase, and the curing time increases. The Tg can be adjusted between 100°C and 140°C. Based on the above method, an epoxy resin shape memory polymer with a shape memory deformation temperature of 110-115°C can be obtained. After foaming Prepared into an epoxy resin shape memory polymer with a foam structure, and compressed at 110-125°C to form a sheet. After cooling the temperature to room temperature, the compressed sheet is granulated by a cutting pelletizer. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com