Production process of modified polyester fiber electrostatic flocking fluff

A technology of polyester fiber and electrostatic flocking, which is applied in the field of preparation of electrostatic flocking fluff, can solve the problem of effectively ensuring the uniformity of cutting length of modified polyester, the influence of the flying properties of modified polyester fluff, and the difficulty of cutting modified polyester And other problems, to achieve the effect of improving soaring performance, smooth hand feeling and improving moisturizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

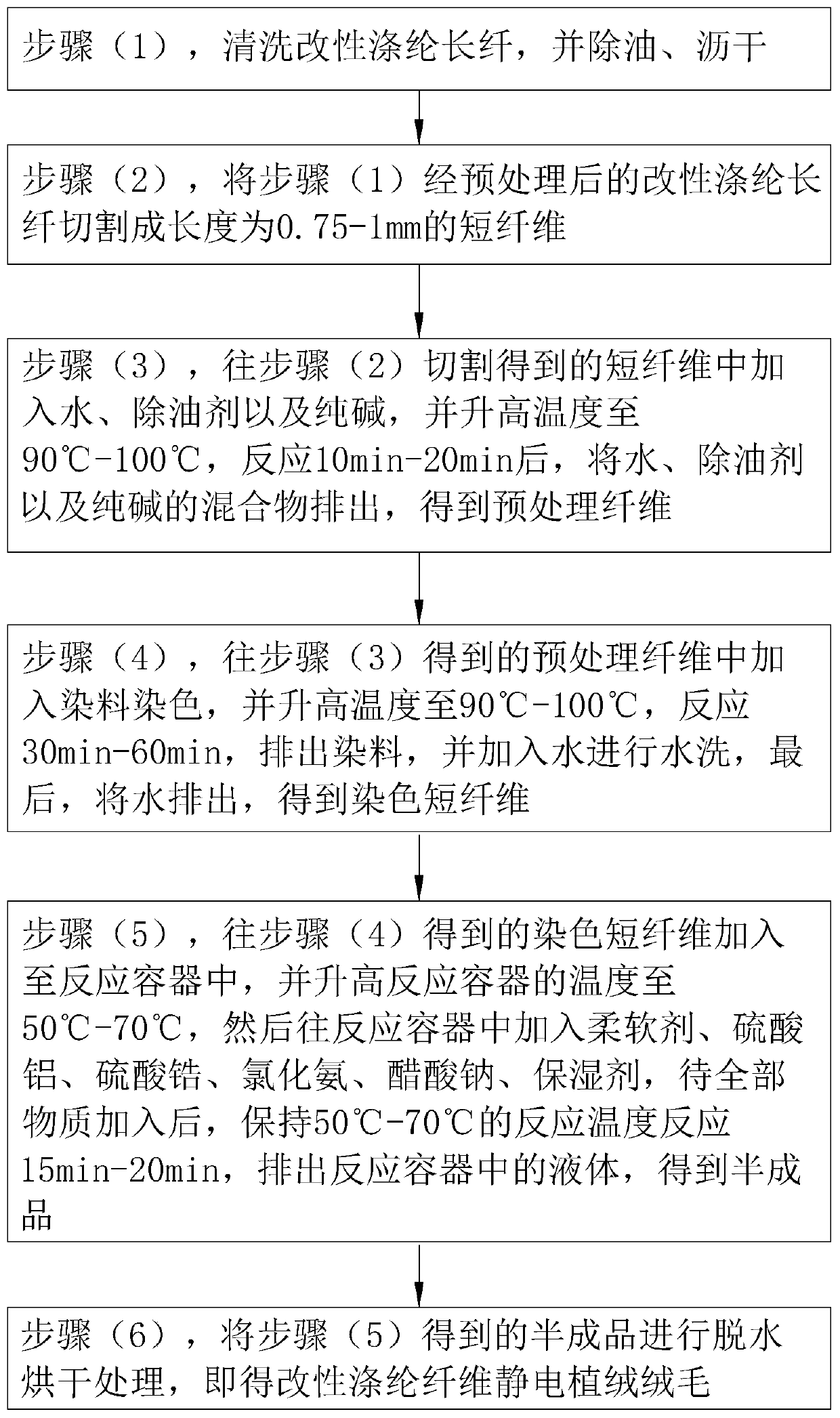

Method used

Image

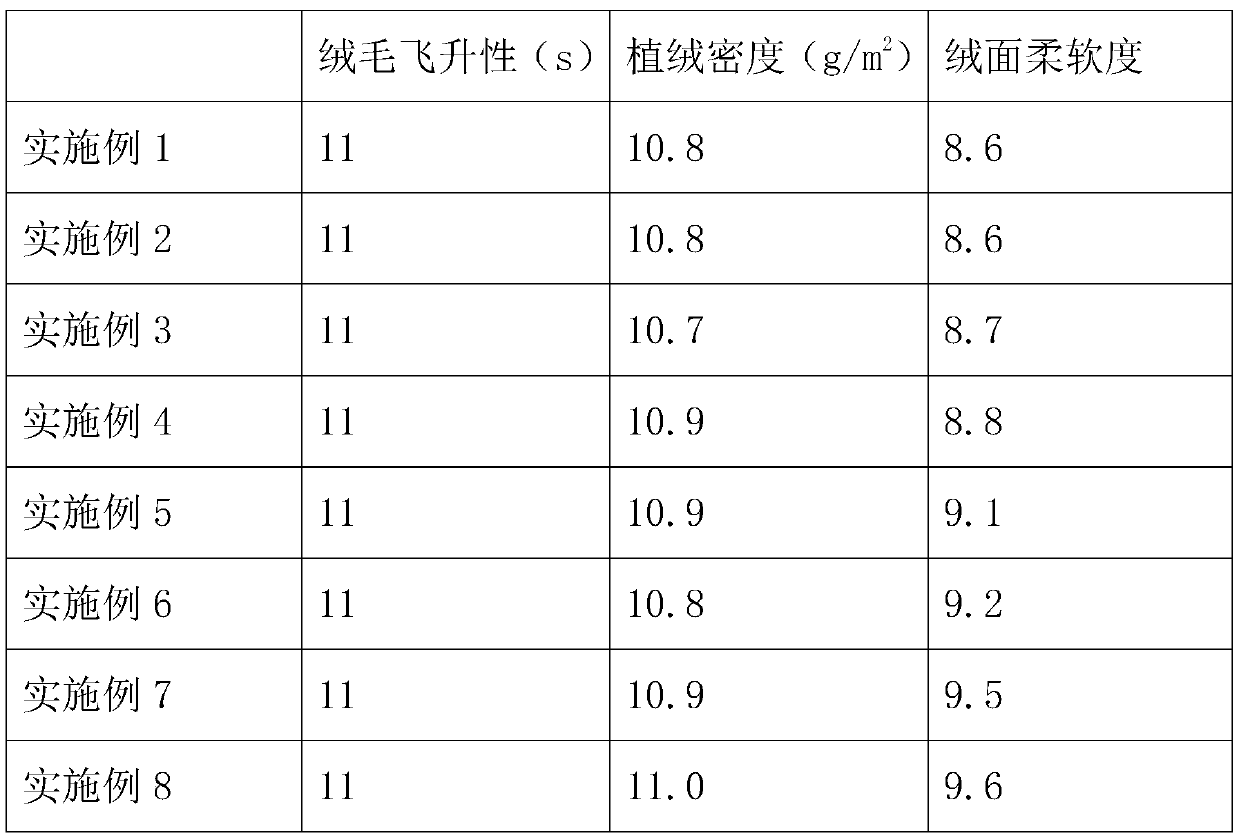

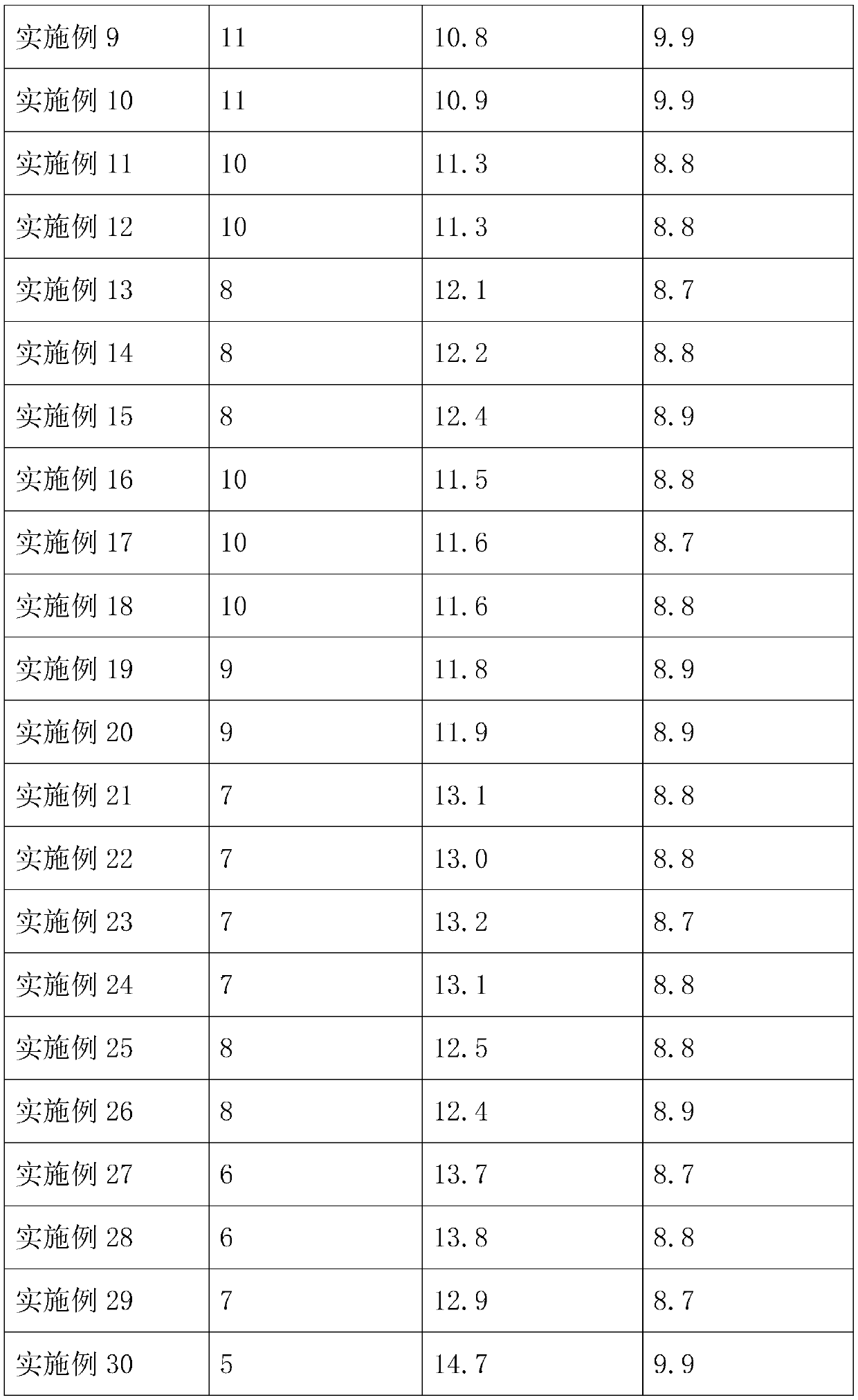

Examples

Embodiment 2

[0098] The difference with embodiment 1 is:

[0099] In the step (1), the cleaned modified polyester long fibers are added to the pressure roller and the moisture is squeezed out, so that the water content of the modified polyester long fibers is 33%.

[0100] In step (2), the modified polyester long fiber is cut into short fibers with a length of 0.88 mm.

[0101] In step (3), raise the temperature in the dye vat to 95° C., and keep it warm for 15 minutes.

[0102] The consumption of each component that adds in the step (3) is as follows:

[0103] 10kg of soda ash; 7.5kg of degreaser; 150kg of water. And the time interval between adding adjacent components is 4.5min.

[0104] In step (4), raise the temperature in the dye vat to 95° C., and keep it warm for 45 minutes.

[0105] In step (5), raise the temperature in the dye vat to 60° C., and keep it warm for 18 minutes.

[0106] The consumption of each component that adds in the step (5) is as follows:

[0107] Moisturiz...

Embodiment 3

[0110] The difference with embodiment 1 is:

[0111] In the step (1), the cleaned modified polyester long fibers are added to the pressure roller and the moisture therein is squeezed out, so that the water content of the modified polyester long fibers is 36%.

[0112] In step (2), the modified polyester long fiber is cut into short fibers with a length of 1 mm.

[0113] In step (3), raise the temperature in the dye vat to 100° C., and keep it warm for 10 minutes.

[0114] The consumption of each component that adds in the step (3) is as follows:

[0115] 6kg of soda ash; 5kg of degreaser; 200kg of water. And the time interval between adding adjacent components is 5min.

[0116] In step (4), raise the temperature in the dye vat to 100° C., and keep it warm for 30 minutes.

[0117] In step (5), raise the temperature in the dye vat to 70° C., and keep it warm for 15 minutes.

[0118] The consumption of each component that adds in the step (5) is as follows:

[0119]Moisturi...

Embodiment 4

[0122] The difference with embodiment 1 is:

[0123] In the step (1), the cleaned modified polyester long fibers are added to the pressure roller and the moisture is squeezed out, so that the water content of the modified polyester long fibers is 35%.

[0124] In step (2), the modified polyester long fiber is cut into short fibers with a length of 1 mm.

[0125] In step (3), raise the temperature in the dye vat to 98° C., and keep it warm for 15 minutes.

[0126] The consumption of each component that adds in the step (3) is as follows:

[0127] 7kg of soda ash; 8kg of degreaser; 180kg of water. And the time interval between adding adjacent components is 5min.

[0128] In step (4), raise the temperature in the dye vat to 98° C., and keep it warm for 40 minutes.

[0129] In step (5), raise the temperature in the dye vat to 60° C., and keep it warm for 20 minutes.

[0130] The consumption of each component that adds in the step (5) is as follows:

[0131] Moisturizing agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com