Remote control type hydraulic support electrohydraulic control system

An electro-hydraulic control system and hydraulic support technology, which is applied in the direction of pillars/supports, short-distance communication services, mining equipment, etc., can solve problems such as non-operation, jumping, and unstable operation of infrared receivers, so as to improve stability and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

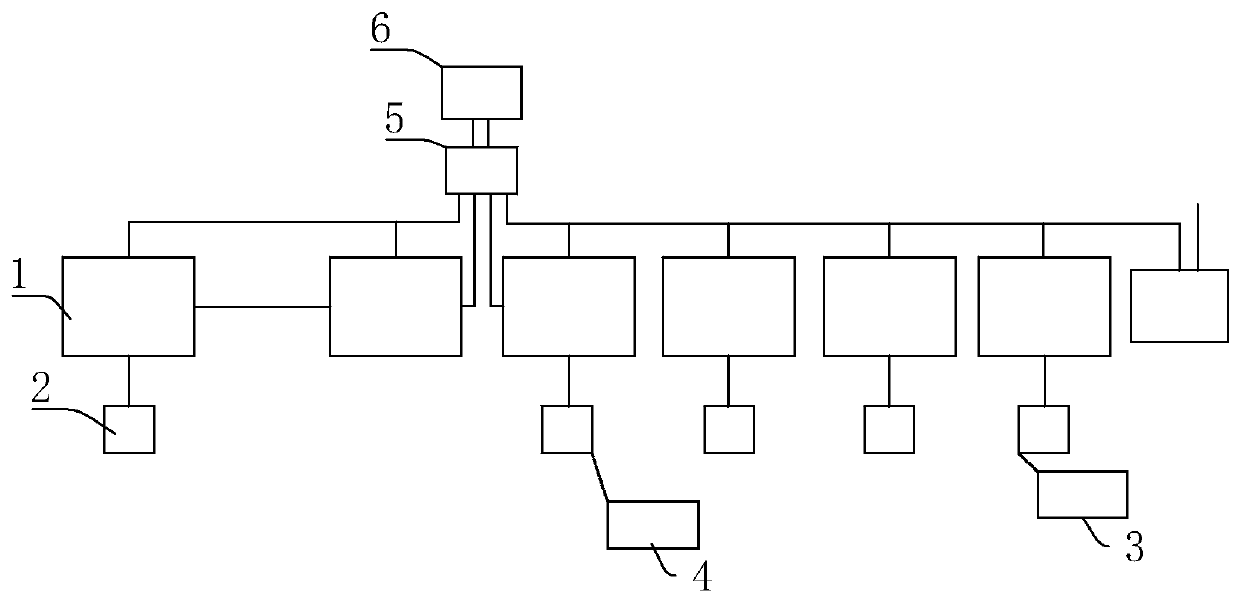

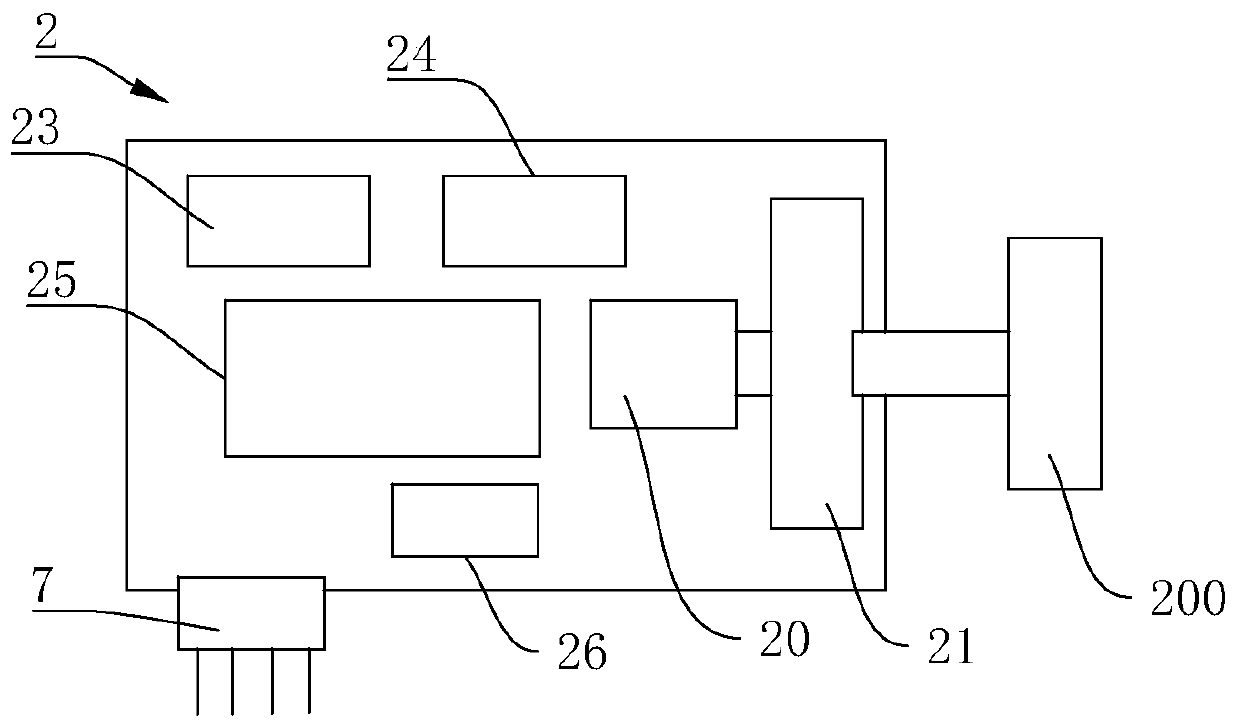

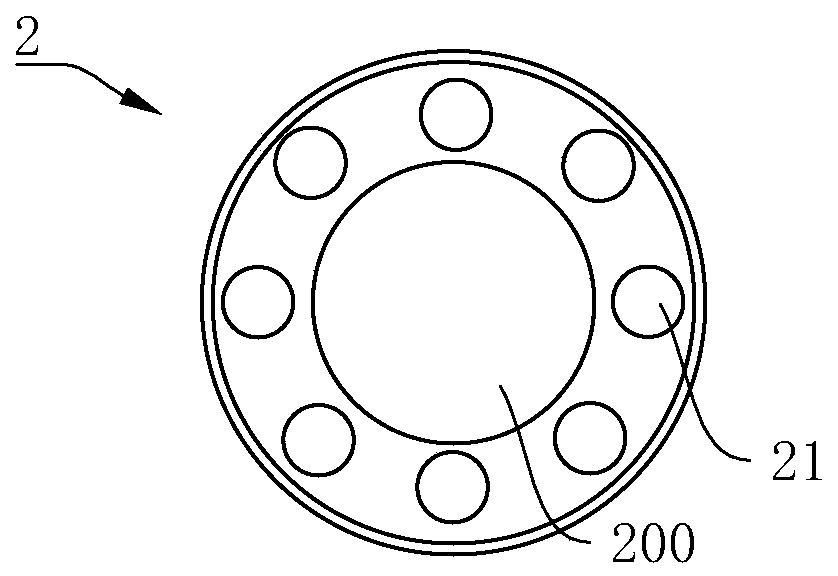

[0037] Such as Figure 1 to Figure 4 As shown together, a remote-controlled hydraulic support electro-hydraulic control system includes multiple hydraulic supports, a shearer position transmitting device 4, a coupler 5, and a power supply box 6. Each hydraulic support includes a support controller 1 and an electrically connected support. The multifunctional emergency stop switch device 2, the support controller 1 is sealed on the hydraulic support, and the multifunctional emergency stop switch device 2 is independently set.

[0038] The power supply box 6 supplies power to the rack controller 1, the multi-function emergency stop switch device 2 and the coupler 5;

[0039] Wherein the multifunctional emergency stop switch device is provided with an emergency stop switch 20 for emergency stop locking.

[0040] The system also includes at least one bracket remote controller 3, the bracket remote controller 3 is provided with a keyboard for human-computer interaction, the bracket...

Embodiment 2

[0068] Such as Figure 5 As shown, this embodiment is basically the same as Embodiment 1, the difference is:

[0069] The wireless communication adopts ZigBee wireless communication technology, that is, the first wireless communication module, the second wireless communication module and the third wireless communication module are all ZigBee wireless communication modules, and use ZigBee wireless communication to perform wireless distance measurement.

[0070] Zigbee is a 2.4GHz frequency band 250kb / s low-speed, low-power consumption, short-distance (10-75m), low-latency wireless communication technology. Zigbee ranging principle such as Figure 5 As shown, the ranging technology based on RSSI uses the principle that the radio signal decays regularly as the distance increases to measure the distance between nodes. The relationship between the received signal strength RSSI and the transmission distance d is as follows:

[0071] RSSI=-(10×n×lgd+A)

[0072] d=10^((abs(RSSI)-A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com