Non-fried composite potato chip and processing method thereof

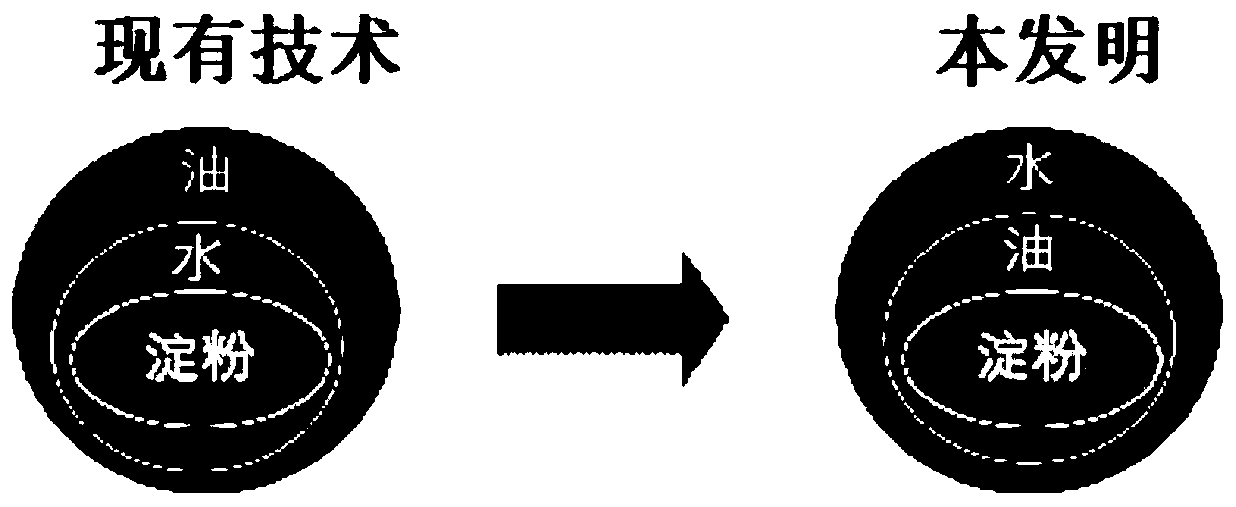

A processing method and a non-fried technology, which are applied to the non-fried composite potato chips and the processing field thereof, can solve the problems of easy stickiness, poor taste, and high oil content of potato chips, and achieve good taste, full aroma, and high melting point. good mouth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

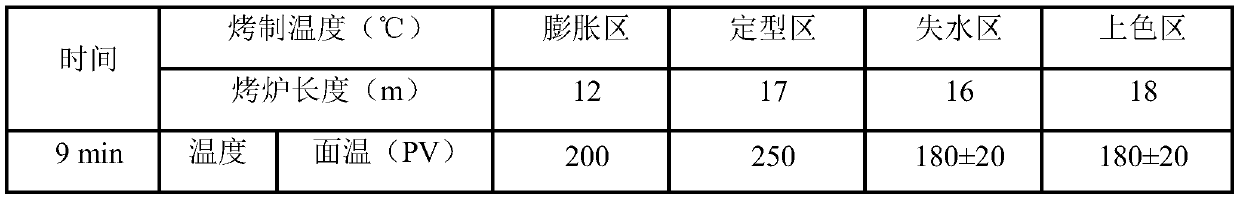

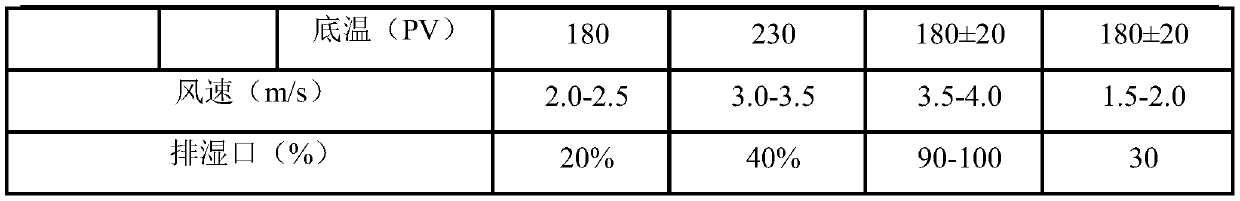

[0034] The present embodiment provides a kind of processing method of non-fried compound potato chips, and concrete steps are as follows:

[0035] Preparation before production:

[0036] (1) Production of mashed potatoes: Choose Dutch series potatoes without germination or rot. After cleaning, the machine peels and slices about 30mm, and puts them into continuous infrared baking. After the potatoes are baked, immediately put them into a mixing device with cooling function. Stir into mashed potatoes and put them in -18°C cold storage for later use; when baking, use infrared rays to penetrate the inside of the potato tissue, causing water molecules to vibrate to generate heat, so as to achieve the purpose of baking and full of fragrance; at the same time, it is different from steamed potatoes. The moisture content of mashed potatoes baked by infrared rays is relatively low;

[0037] (2) Preparation of seasoning liquid: select hen about 180 days old (not to use internal organs),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com