Fuel reaction device for producing hydrogen

A fuel reaction and reaction device technology, applied in hydrogen/syngas production, hydrogen, inorganic chemistry, etc., can solve the problems of high reaction temperature, complex structure, poor thermal conductivity, etc., and achieve high heat utilization, high integration, and thermal conductivity. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following non-limiting examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

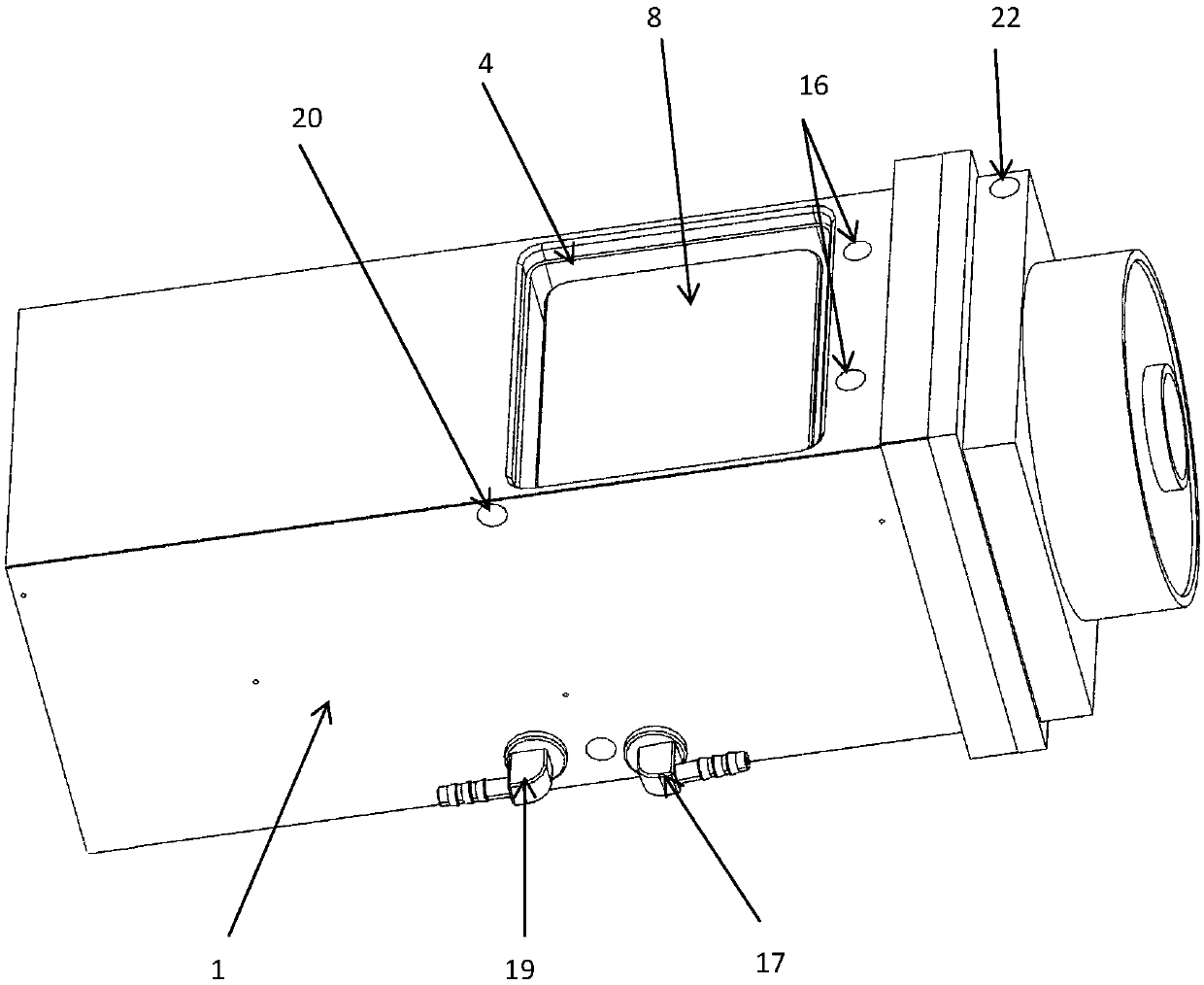

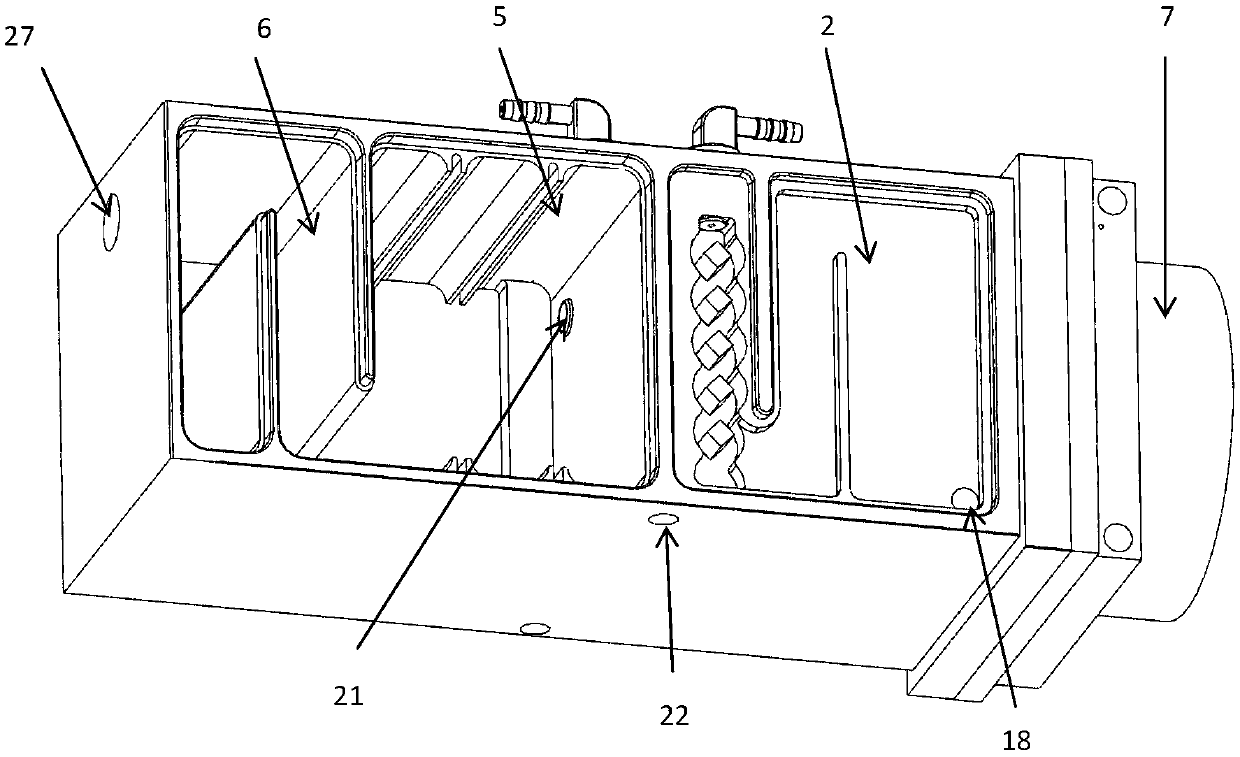

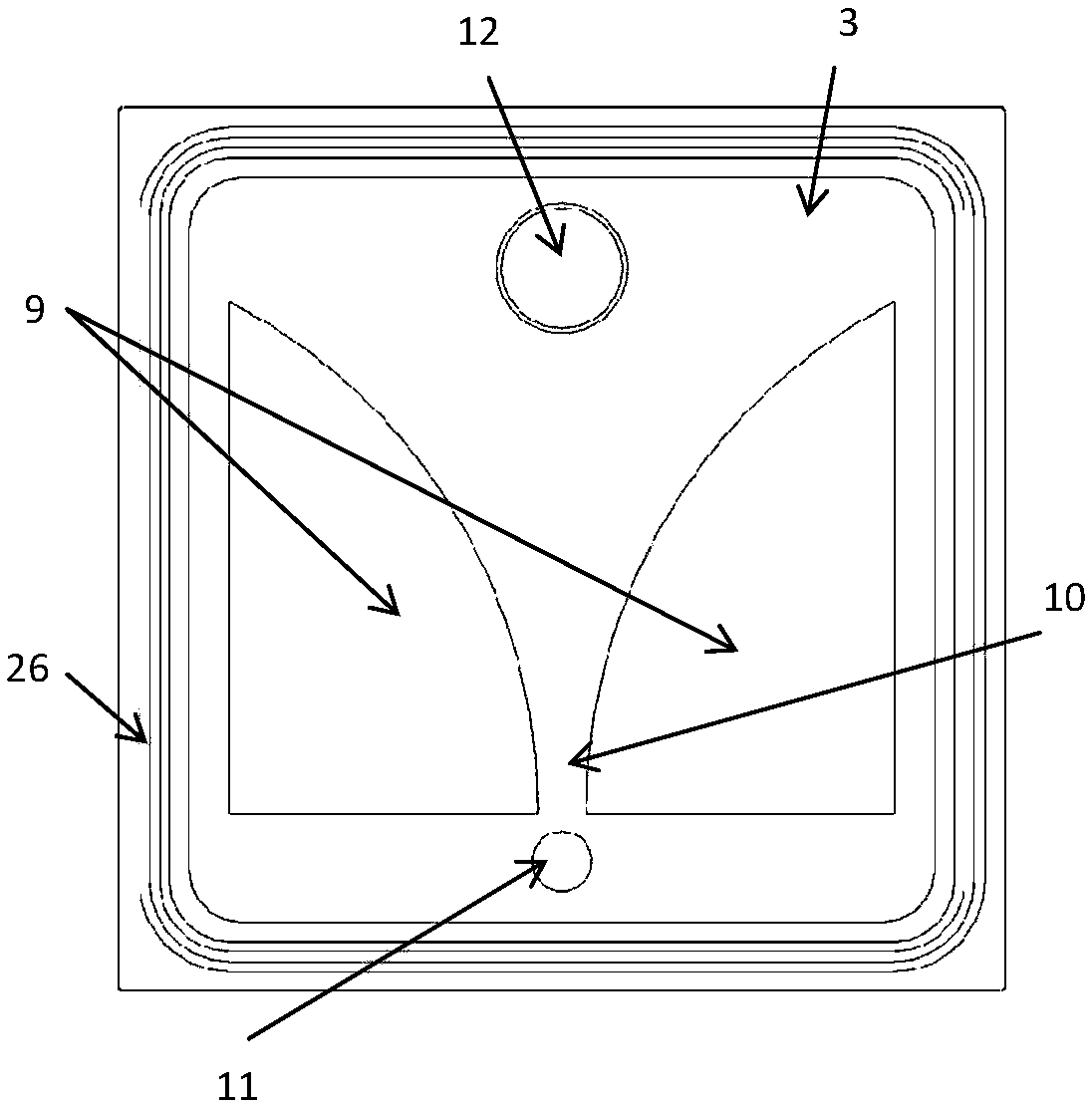

[0048] A fuel reaction device for producing hydrogen, comprising: a reaction device main body 1 with a hollow cavity, a heating element for heating the reaction device, a reaction catalyst, an inlet and outlet liquid and gas connection auxiliary parts; , Outlet liquid and gas connection auxiliary parts include liquid spectrum fuel inlet aluminum alloy joint and water vapor inlet aluminum alloy joint. The above two auxiliary parts are made of right-angle L-shaped aluminum alloy material. The internal threaded interface at the corresponding position is connected, and the other end is designed with a pagoda joint to connect with the hose.

[0049] The fuel reaction device is provided with a reaction device heating element for heating the reaction device, the inner cavity of the reaction device main body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap