Extraction method of alpinia zerumbet essential oil

An extraction method, ginger essential oil technology, applied in the direction of essential oil/spices, fat production, etc., can solve the problem of low extraction efficiency, achieve the effect of simple and convenient operation, strong practicability, and increase the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

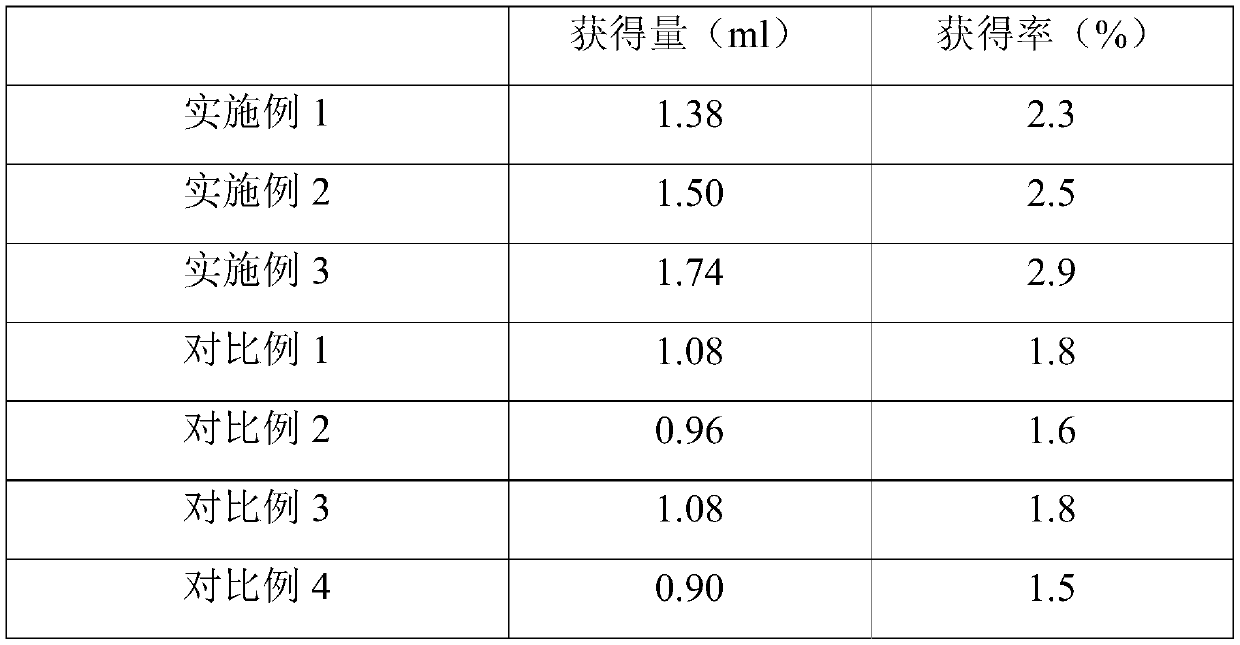

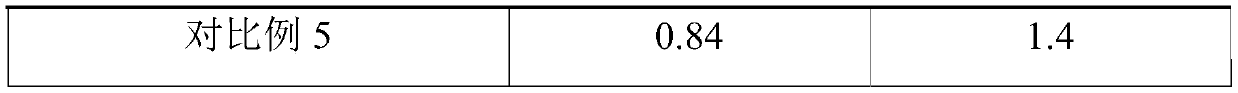

Examples

Embodiment 1

[0041] A method for extracting Yanshanjiang essential oil, comprising the following steps:

[0042] (1) Screening the dried fruit of Alpinia japonicus to remove impurities and mildewed fruit, then pulverize and pass through a 20-mesh sieve to obtain powder;

[0043] (2) Add water to the powder obtained in step (1) to make the ratio of material to liquid reach 1:4.5, mix well, soak at room temperature for 10 minutes, and then ultrasonicate for 5 minutes at 40°C with ultrasonic power of 15KHz;

[0044] (3) Distill and extract the treated mixed solution in step (2) for 200 min at 60° C. by steam distillation;

[0045] (4) Add sodium chloride powder to the mixed solution of step (3), make the mass concentration of sodium chloride in the solution reach 1.0%, continue distillation extraction 30min;

[0046] (5) Collect the distillate distilled in step (3) and step (4), let it stand, separate and obtain the upper layer oily liquid, add anhydrous sodium sulfate thereinto, shake, sepa...

Embodiment 2

[0048] A method for extracting Yanshanjiang essential oil, comprising the following steps:

[0049] (1) Screening the dried fruit of Alpinia japonicus to remove impurities and mildewed fruit, then pulverize and pass through a 40-mesh sieve to obtain powder;

[0050] (2) Add water to the powder obtained in step (1) to make the material-liquid ratio reach 1:7, mix well, soak at room temperature for 30 minutes, and then ultrasonically treat for 10 minutes at 60°C and ultrasonic power of 20KHz;

[0051](3) Distilling and extracting the treated mixed solution in step (2) for 300 min at 70° C. by means of steam distillation;

[0052] (4) Add sodium chloride powder to the mixed solution of step (3), make the mass concentration of sodium chloride in the solution reach 1.6%, continue distillation extraction 60min;

[0053] (5) Collect the distillate distilled in step (3) and step (4), let it stand, separate and obtain the upper layer oily liquid, add anhydrous sodium sulfate thereinto...

Embodiment 3

[0055] A method for extracting Yanshanjiang essential oil, comprising the following steps:

[0056] (1) Screening the dried fruit of Alpinia japonicus to remove impurities and mildewed fruit, then pulverize and pass through a 40-mesh sieve to obtain powder;

[0057] (2) Add water to the powder obtained in step (1) to make the ratio of material to liquid reach 1:6, mix well, soak at room temperature for 26 minutes, and then ultrasonicate for 7 minutes at 50°C with ultrasonic power of 16KHz;

[0058] (3) Distill and extract the treated mixed solution in step (2) for 180 min at 65° C. by means of steam distillation;

[0059] (4) Add sodium chloride powder to the mixed solution of step (3), make the mass concentration of sodium chloride in the solution reach 1.2%, continue distillation extraction 40min;

[0060] (5) Collect the distillate distilled in step (3) and step (4), let it stand, separate and obtain the upper layer oily liquid, add anhydrous sodium sulfate thereinto, shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com