Bridge construction stress detection system based on blockchain

A technology for bridge construction and stress detection, applied in force/torque/work measuring instruments, measuring force, measuring devices, etc., can solve problems such as the imbalance of the linear relationship of ultrasonic signals, the aging of stress sheet adhesives, and the reduction of stress resolution , to achieve the effects of good amplification gain regulation, high linearity, and reduced noise sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

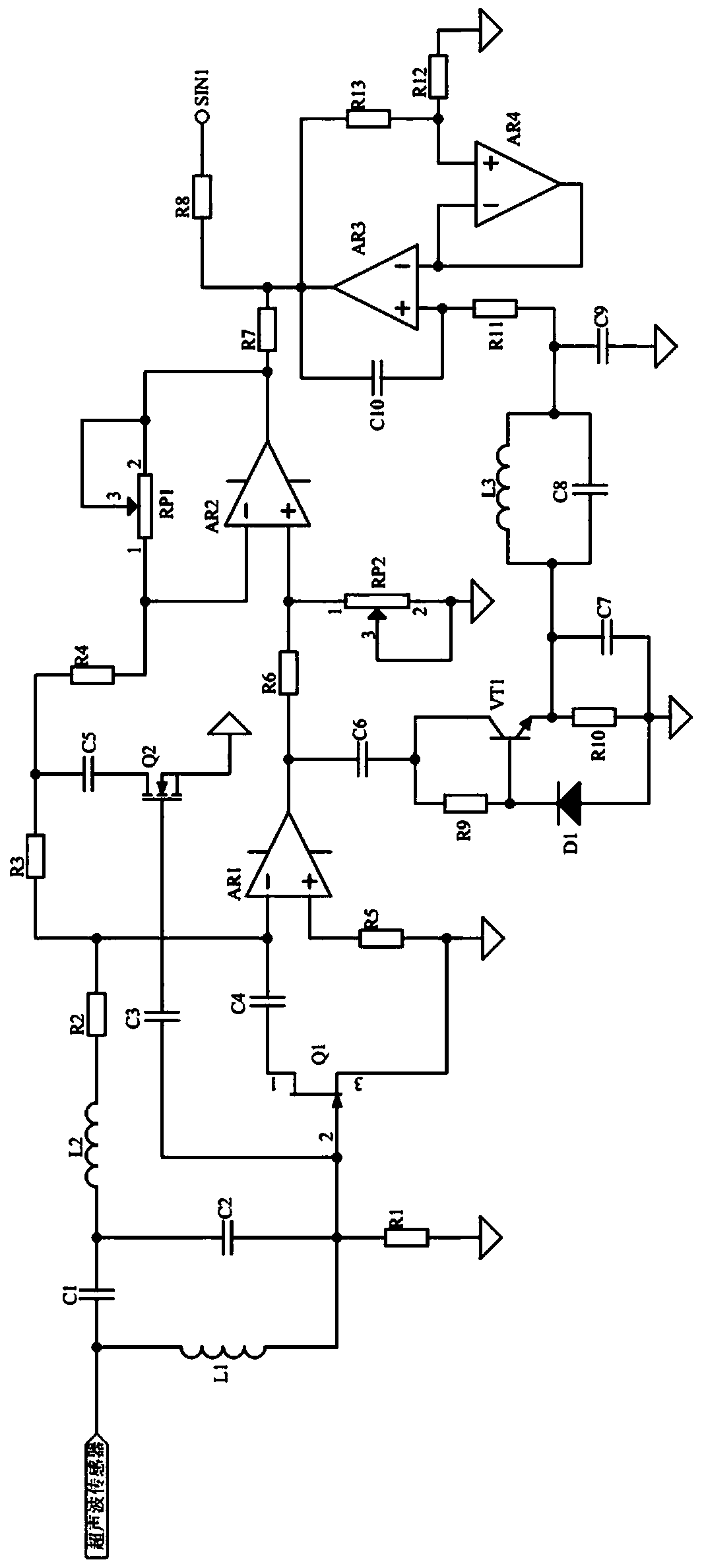

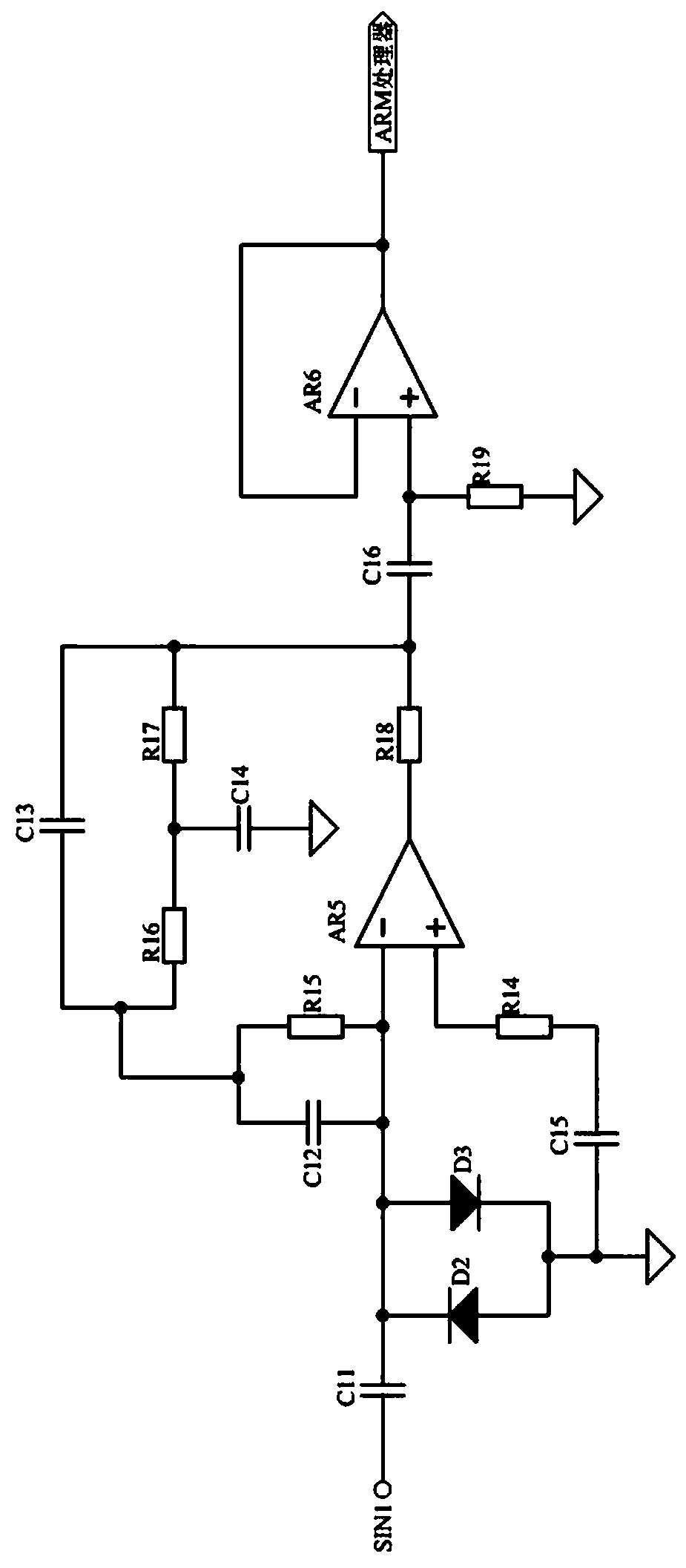

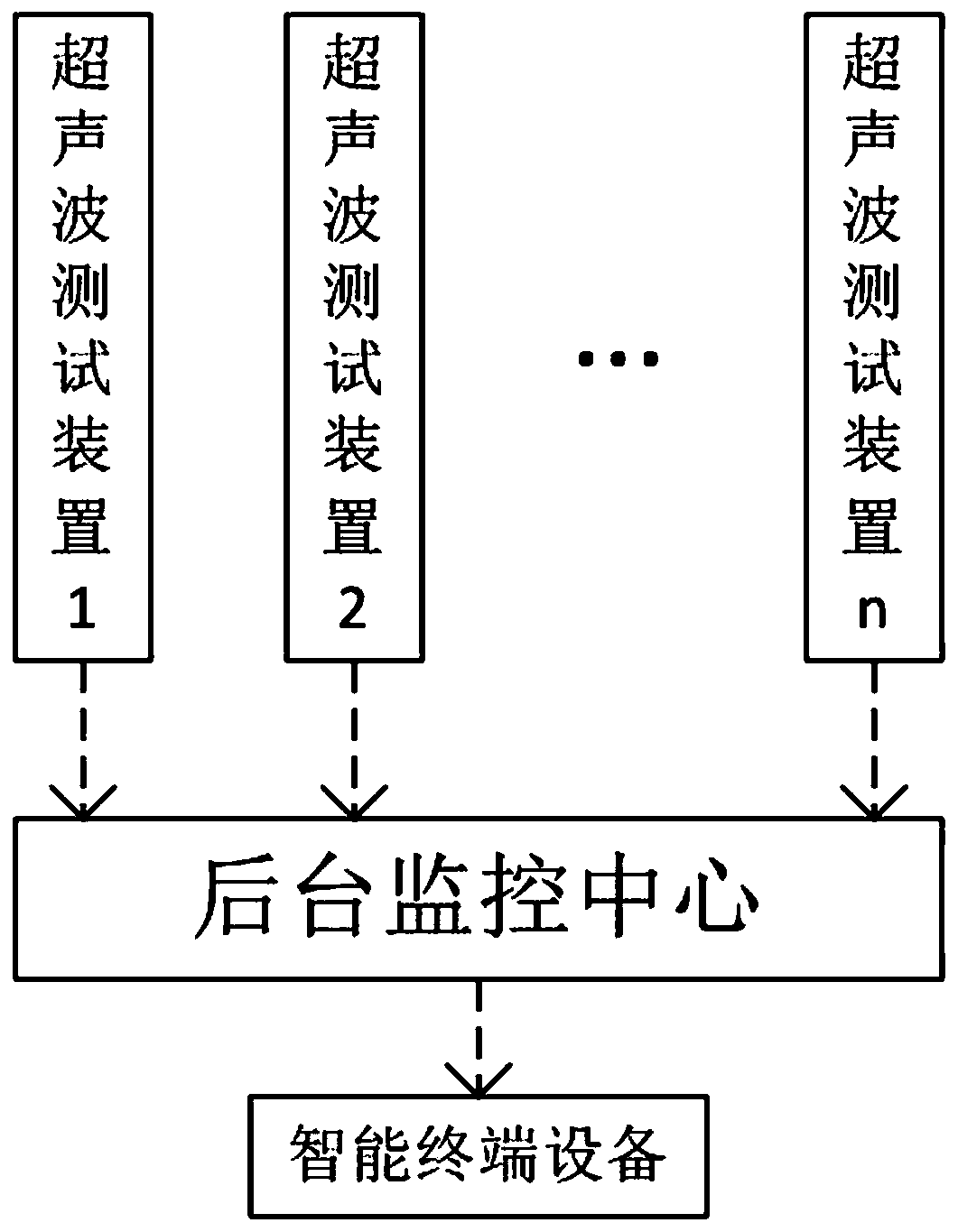

[0015] Regarding the aforementioned and other technical contents, features and effects of the present invention, refer to the appended figure 1 to attach image 3 It will be apparent from the detailed description of the embodiments. The structural contents mentioned in the following embodiments are all based on the accompanying drawings of the description.

[0016] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

[0017] A bridge construction stress detection system based on blockchain, including ultrasonic testing device, WIFI module and background monitoring center. The ultrasonic test device includes an ultrasonic sensor, a signal receiving and processing module and an ARM processor. The signal processing module includes an impedance matching circuit, an anti-interference amplifier circuit and a frequency selection output circuit. After the output signal of the ultrasonic sensor is processed by the impeda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com