A low-temperature-resistant seawater-resistant high-expansion foam fire extinguishing agent and its preparation and use method

A foam fire extinguishing agent, seawater-resistant technology, applied in the field of foam fire extinguishing agent, can solve the problems of complex components, short storage period, high cost, etc., and achieve the effect of simple preparation process, low manufacturing cost and better foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

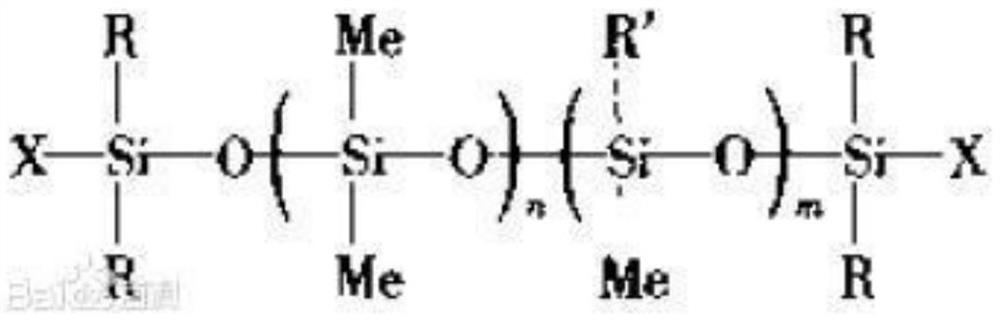

Method used

Image

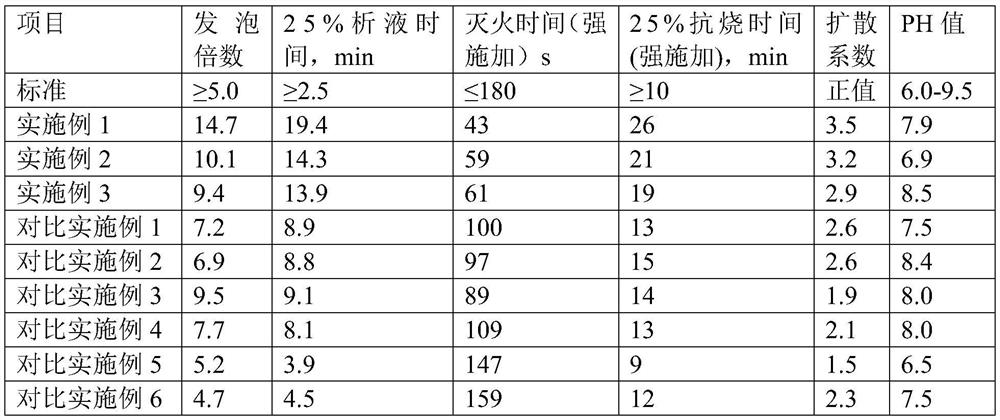

Examples

Embodiment 1

[0056] Heat the mixing reactor to 55-60°C, add 20kg of water, 65kg of fluorocarbon surfactant FC1157, 28kg of sodium methylcocoyl taurate, stir for 30min, and then add 18kg of diisooctyl succinate in sequence Sodium sulfonate, 5kg of a mixture of ethylene glycol and propylene glycol (the volume ratio of ethylene glycol and propylene glycol is 4:6) and 18kg of dodecyl ether, continued to stir for 30min to obtain component A.

[0057] Add polyether modified silicone oil DY-ET101 into water and stir evenly to form a solution with a mass percentage of 60 wt%, to obtain component B.

[0058] The volume ratio of component A and component B is 7.5:2.5, and component A and component B will be stored separately.

Embodiment 2

[0060] Component A and component B were prepared according to the same method as in Example 1, except that the volume ratio of component A and component B was 8:2.

Embodiment 3

[0062] Component A and component B were prepared in the same manner as in Example 1, except that the volume ratio of component A and component B was 7:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com